Forced air cooling general machine housing assembly

A technology of forced air cooling and outer cover, which is applied in the direction of engine components, mechanical equipment, machines/engines, etc., can solve problems such as the lack of cooperation between the shroud and the fan cover, the impact of the airtightness of the cooling space, and the impact on the heat dissipation effect, etc., to achieve Compact structure, guaranteed airtightness, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

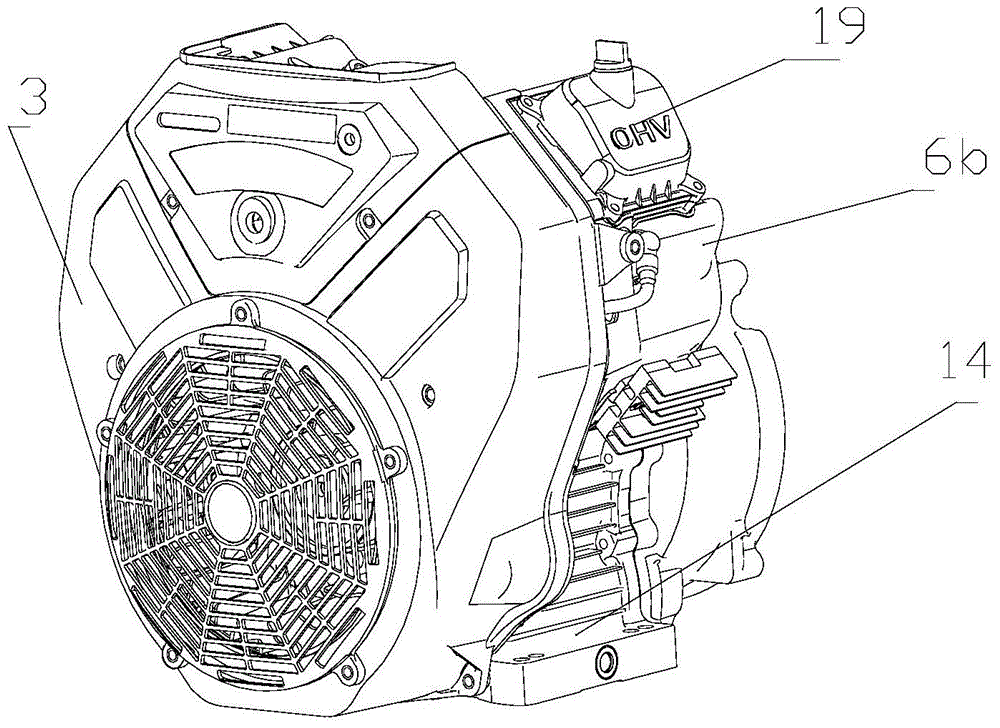

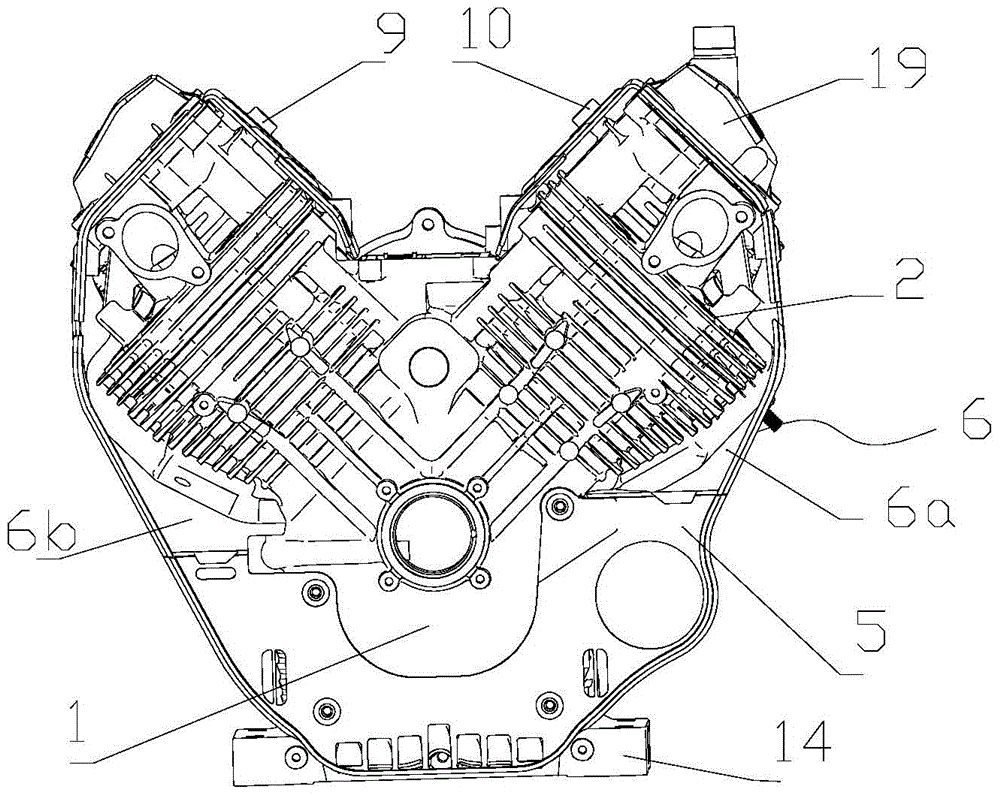

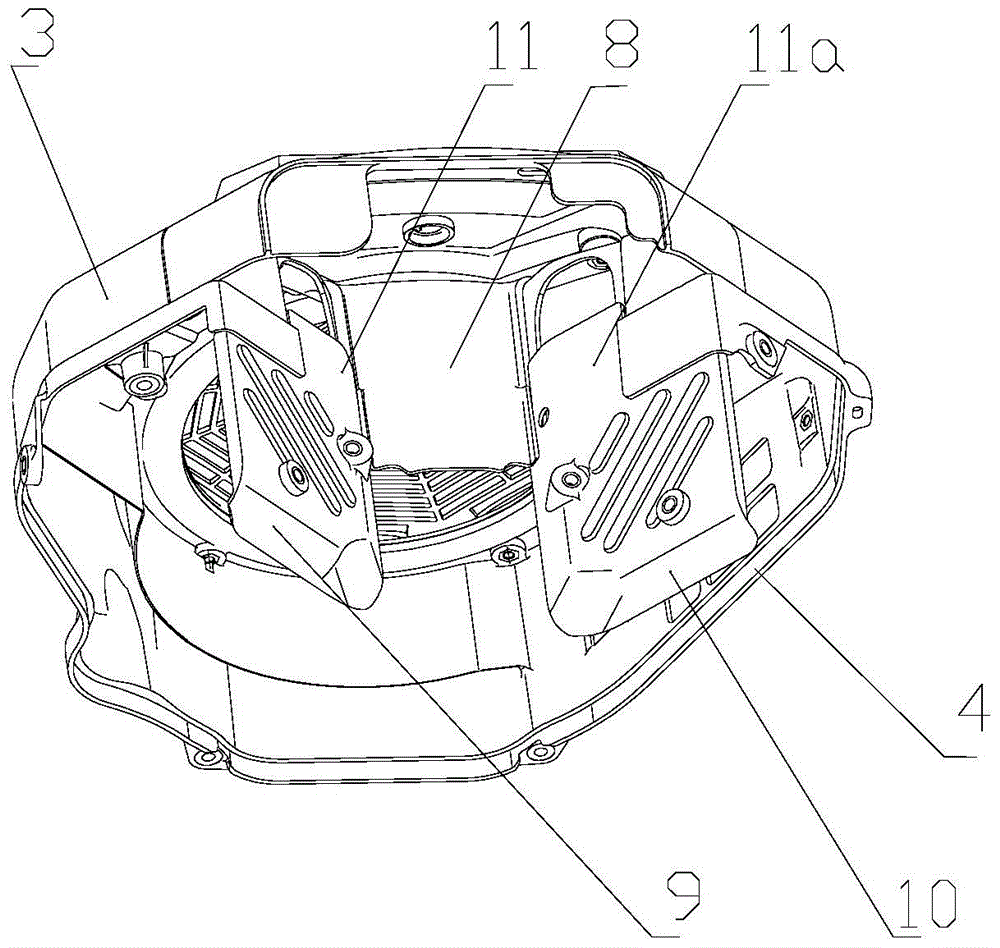

[0024] As shown in the figure: the ventilator with a close-fitting windshield in this embodiment of this embodiment includes a fan casing 3 and a penetrating airtight air passage closely attached to the edge of the fan casing in the circumferential direction for cooling the ventilator The wind guide cover assembly; the structure of the present invention is suitable for forced air cooling ventilation machines, wherein the fan cover 3 is used to cover the impeller, and the fan cover 3 and the wind guide cover assembly are used to form the casing 1 (crankcase) of the ventilation machine The air duct for cooling with the cylinder head 2. In this embodiment, the fan cover 3 is approximately circular in structure, and its rear end surface is an irregular edge structure. The airtightness of the internal cooling space is high by means of close fit, preventing the loss of cooling airflow, so as to achieve the purpose of ensuring the heat dissipation effect; in addition, the general mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com