Belt material measuring system based on laser ranging

A measurement system, laser scanning ranging technology, applied in measurement devices, optical devices, instruments, etc., can solve problems such as low precision, unformed products, and safety management of radioactive sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

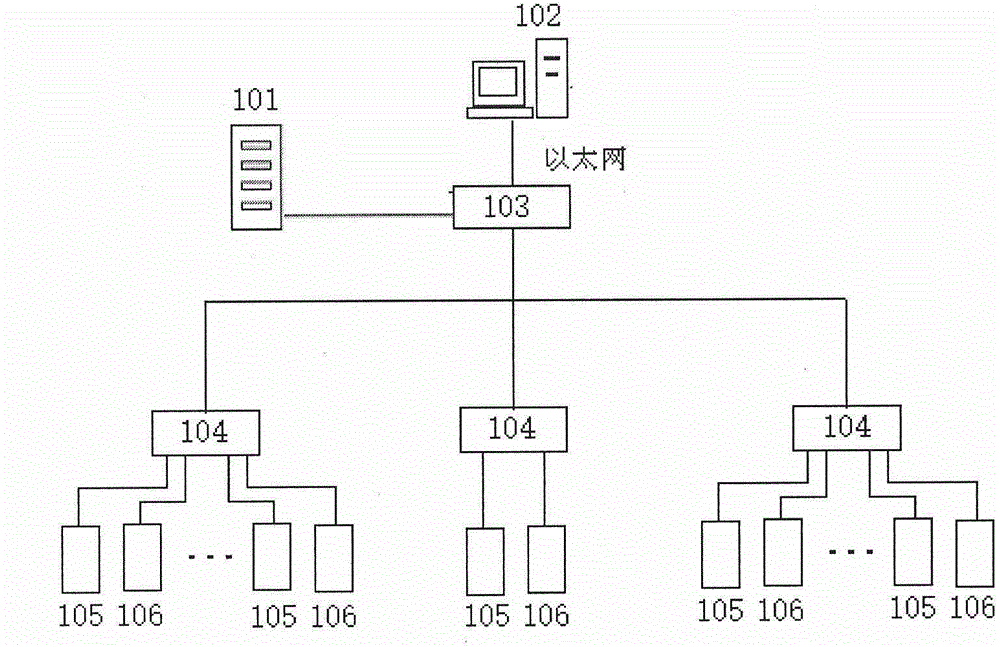

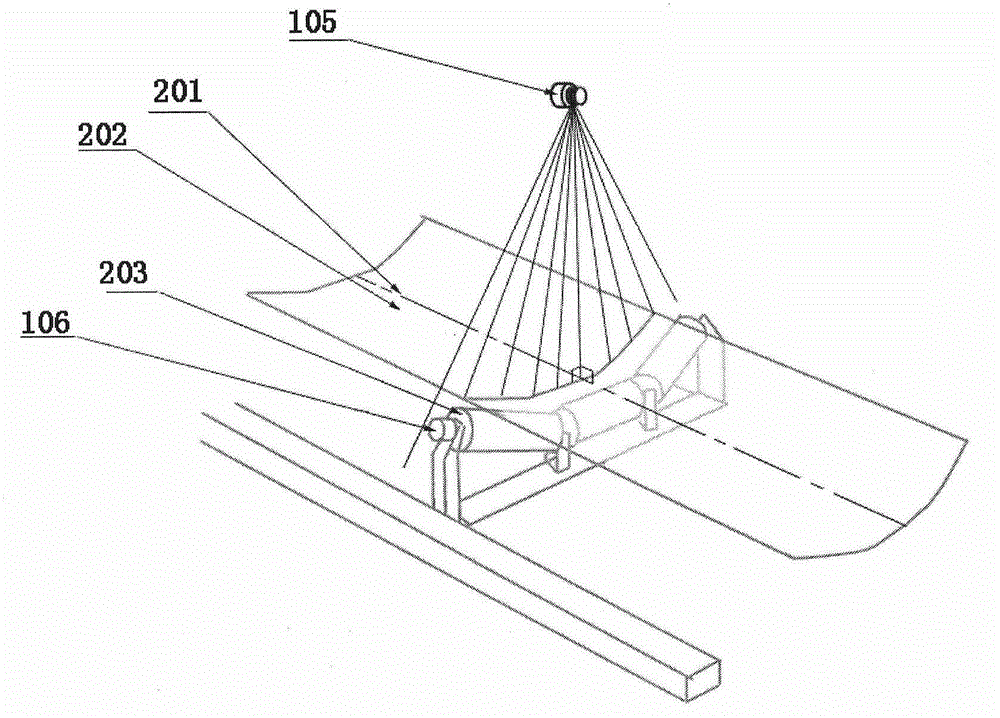

[0019] Such as figure 1 In the implementation example shown, the measurement system includes:

[0020] 1. The statistics server (101) is responsible for receiving the data uploaded by all laser scanning distance measuring equipment and belt speed measuring equipment in the system, and processing the data to obtain the volume and quality of materials conveyed by each belt.

[0021] 2. The monitoring host (102), the production management personnel can check the belt running and the transportation of materials through the monitoring terminal, and can connect the belt control equipment to realize the control of the belt.

[0022] 3. The core switching equipment (103), the core management and switching equipment of the data network, is responsible for the management and data exchange of all equipment connected to the wired network. If the network range is large, use Ethernet networking, if the network is within a certain range, You can also use fieldbus to build a network.

[0023] 4. Acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com