A Micro Thrust Measuring Device with Thermal Protection System

A measuring device and heat protection technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as engine interference, high thruster power, and changes in beam elastic coefficient, so as to facilitate movement and ensure reliability Good performance and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

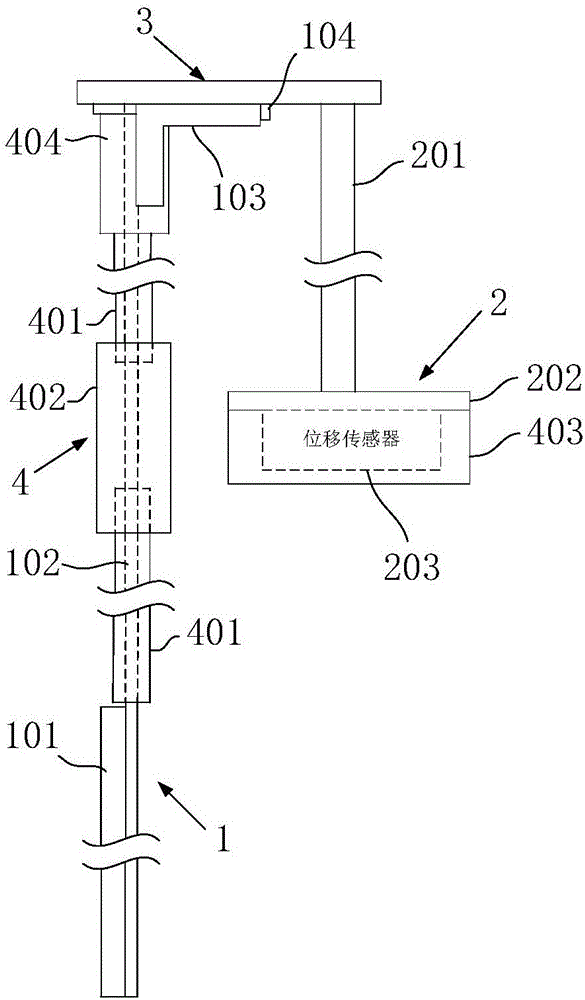

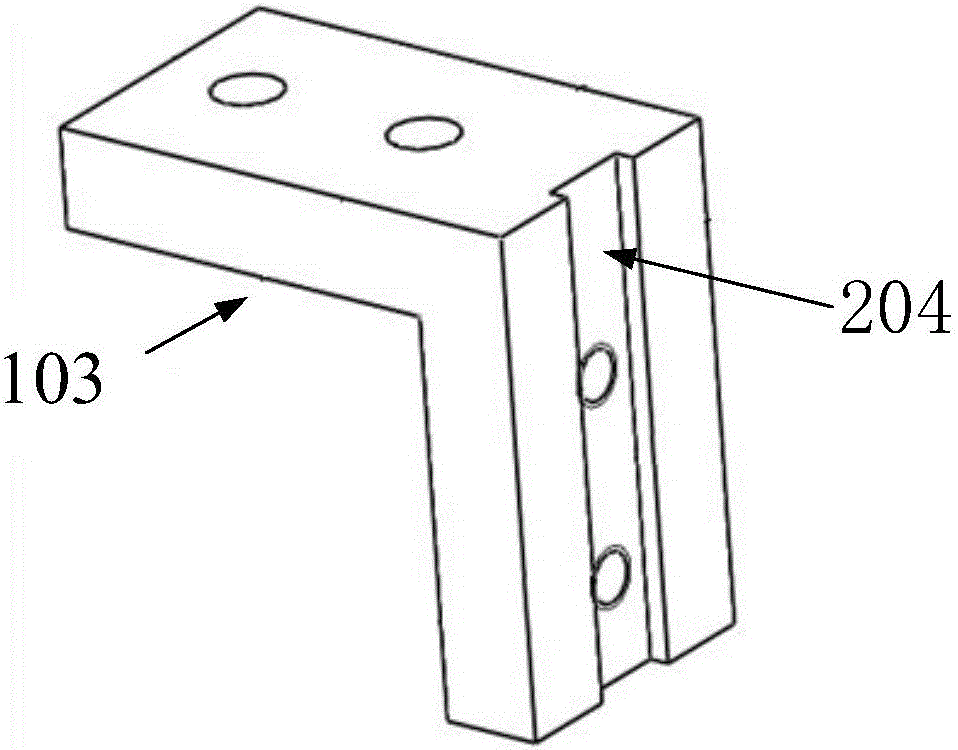

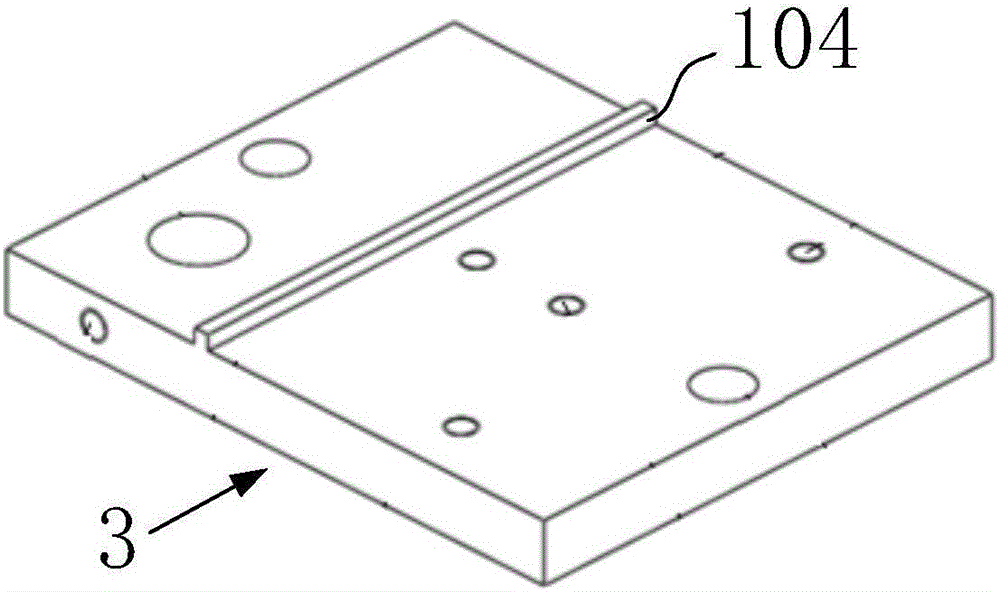

[0035] The measuring device used for micro-thrust measurement of the present invention includes a target system 1, a displacement sensor system 2 and a target mounting block 3, such as figure 1 As shown; Among them, the target system 1 includes the target 101, the elastic beam 102 and the vertical angle aluminum 103; the displacement sensor system 2 includes the sensor installation rod 201, the sensor installation plate 202 and the displacement sensor 203; the target installation block 3 is the target system 1 and the sensor The installation base of the system 2 is used to realize the fixation between the target system 1 and the sensor system 2 and the mobile platform of the external displacement mechanism.

[0036] In the target system 1, the vertical angle aluminum 103 is an L-shaped aluminum piece with a cross-section consisting of a horizontal plate and a vertical plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com