Cryogenic liquid cavitation experimental device

An experimental device and cryogenic liquid technology, applied in measuring devices, fluid dynamics tests, instruments, etc., can solve problems that affect the effect of cavitation experiments, poor heat insulation, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

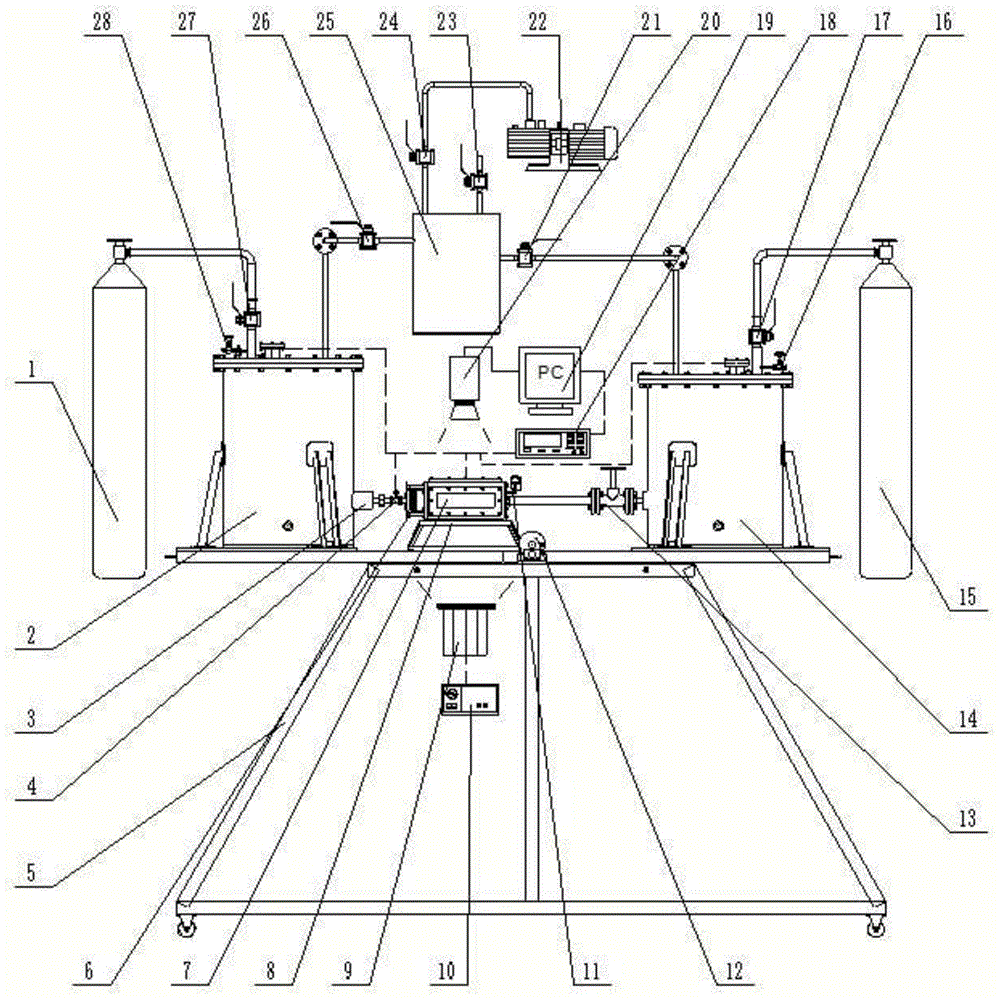

[0046] A low-temperature liquid cavitation experiment device is generally divided into five parts: a supply tank part, a test section part, a collection tank part, a pressure regulating tank part, and an auxiliary equipment part.

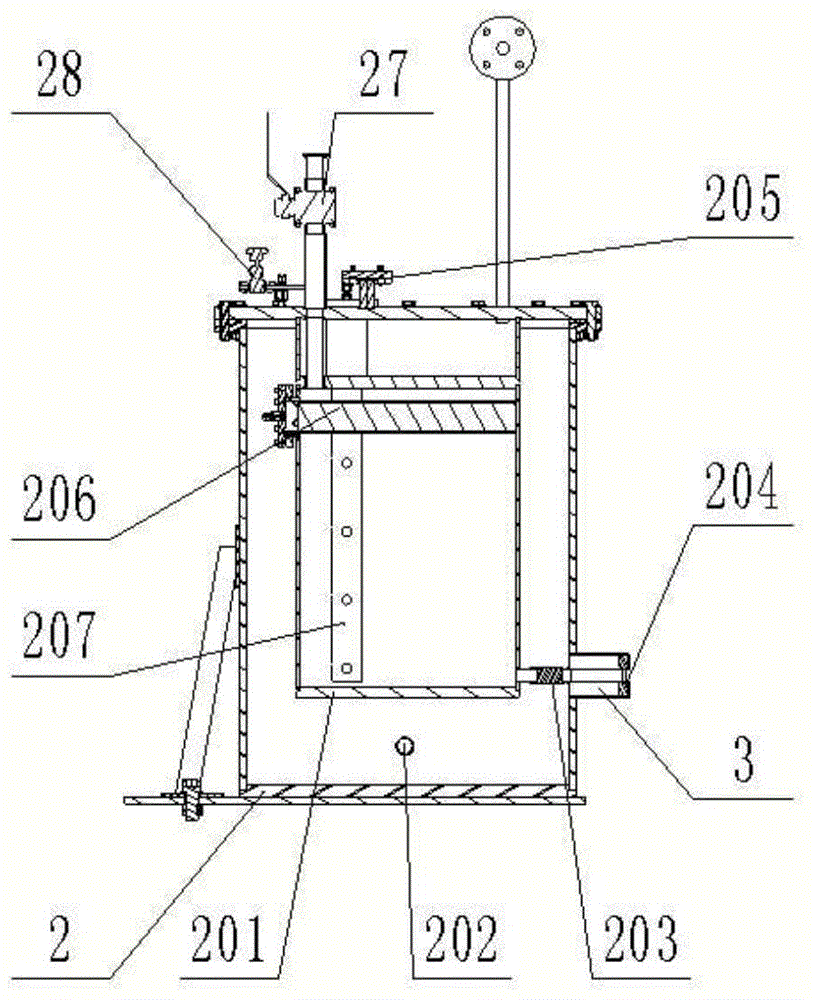

[0047] Supply tank parts such as figure 2As shown, it is used to store and provide cryogenic liquid, and the pressure and temperature of cryogenic liquid can be adjusted; it includes supply tank outer cover 2, supply tank liner 201, supply tank vacuum interface 202, filter joint 203, filter 3, supply tank Tank sealing ring 204, supply tank sensor interface 205, supply tank pressurization valve 27, supply tank pressure relief valve 28, supply tank horizontal level gauge 206, supply tank vertical level gauge 207, connection relationship: supply tank cover 2 upper welding There are 3 brackets, the supply tank bracket and the experimental device bracket 5 are connected by bolts, and the supply tank is fixed on the experimental device bracket 5; the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com