Production control method for ethylene plant based on heuristic algorithm

A production control method and heuristic algorithm technology, applied in computing, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings.

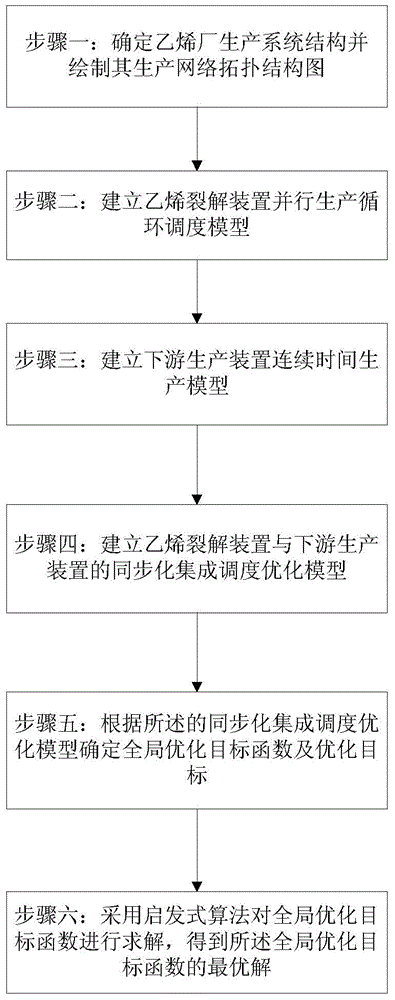

[0070] Such as figure 1 As shown, an ethylene plant scheduling optimization method based on a heuristic algorithm, which specifically includes the following steps:

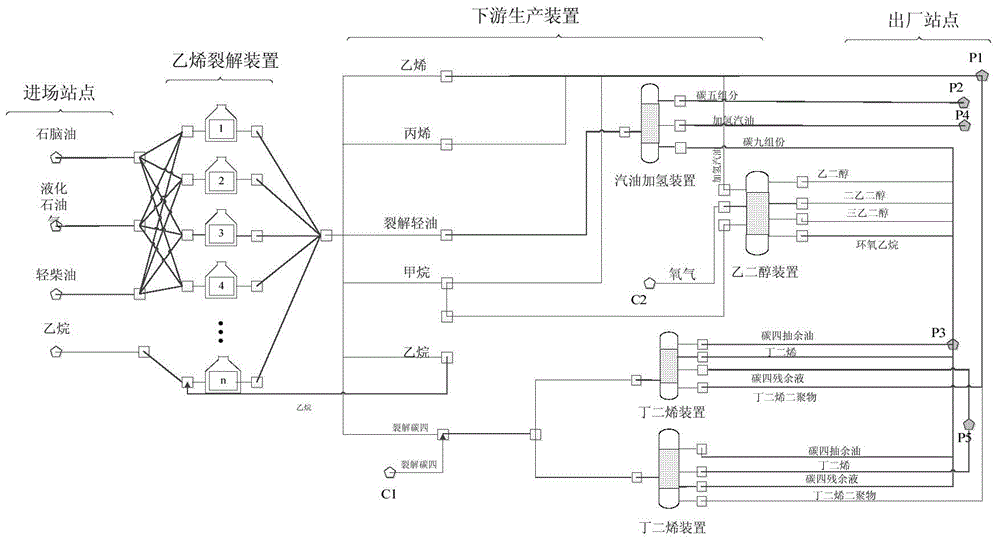

[0071] (1) Divide the production system of the ethylene plant into raw material entry site, product delivery site, ethylene cracking unit and downstream production unit, and draw the corresponding production network topology diagram;

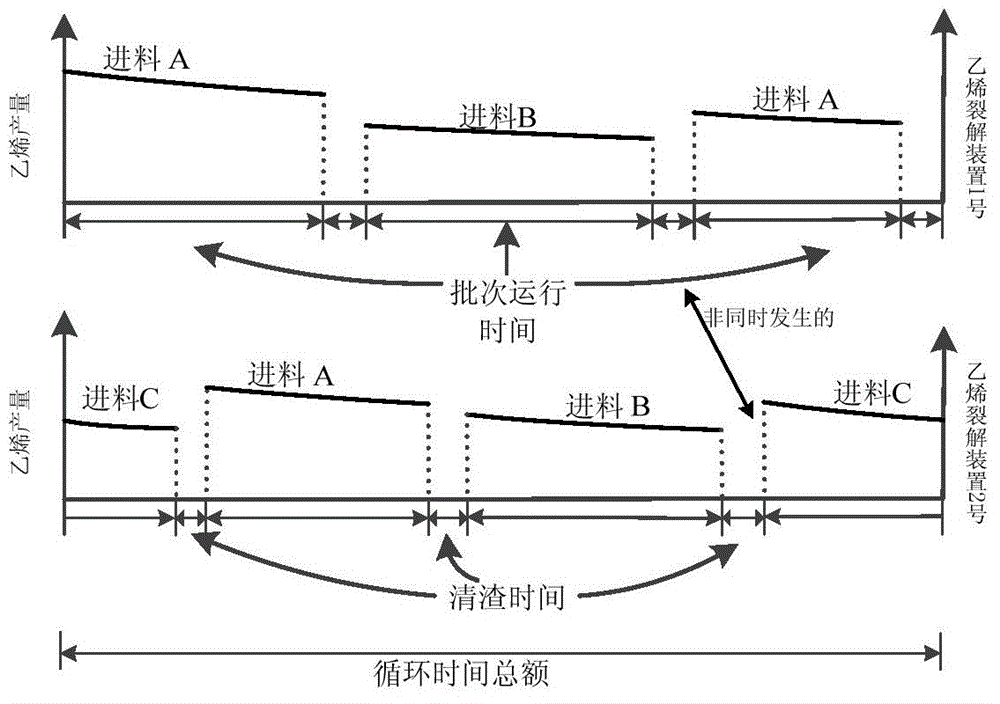

[0072] Firstly, the production system of the ethylene plant is divided into four components, namely: raw material incoming site, product outgoing site, ethylene cracking unit, and downstream production unit; at the same time, the type, ratio and physical property conditions of the raw material incoming site are determined ; To determine the product production site, it is necessary to clarify the type, yield and physical properties of the product; to determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com