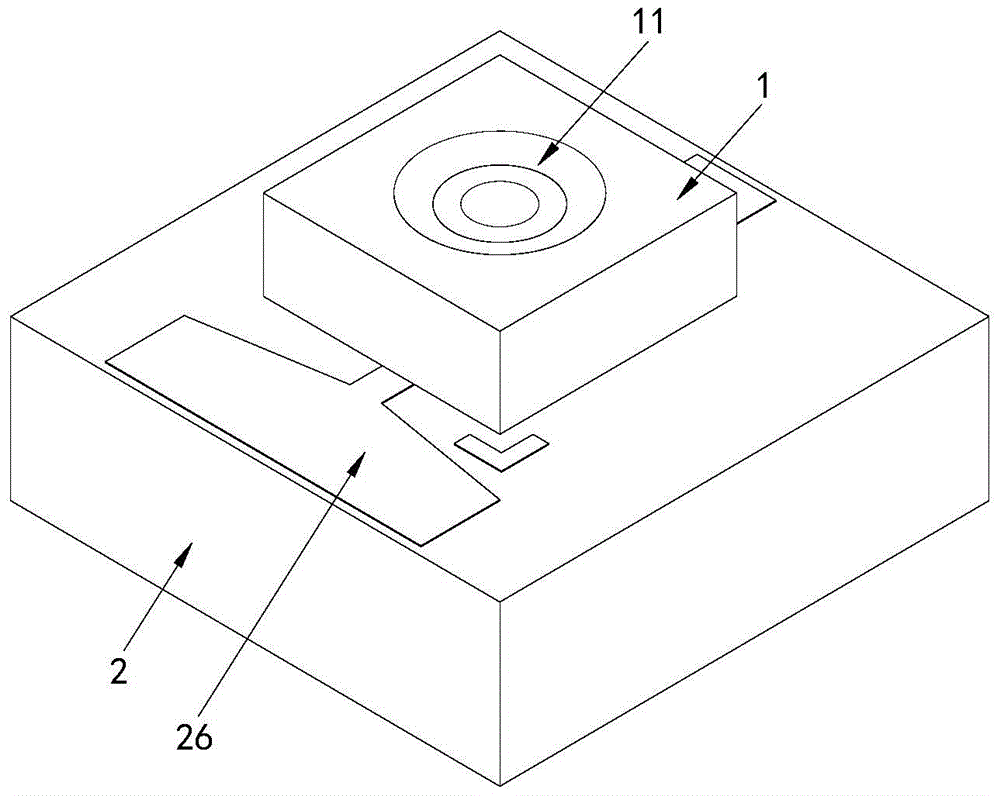

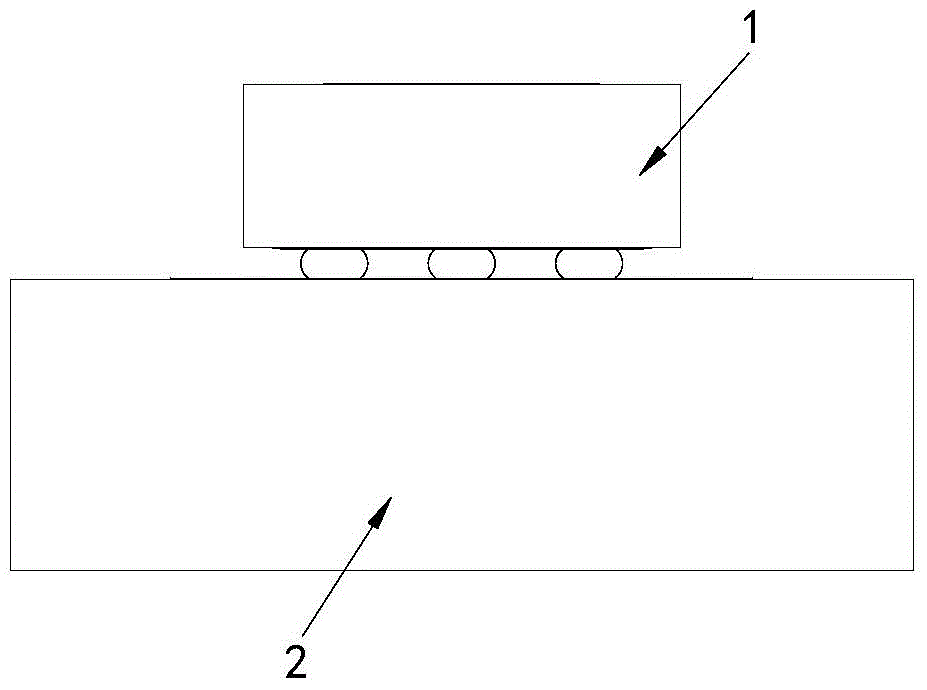

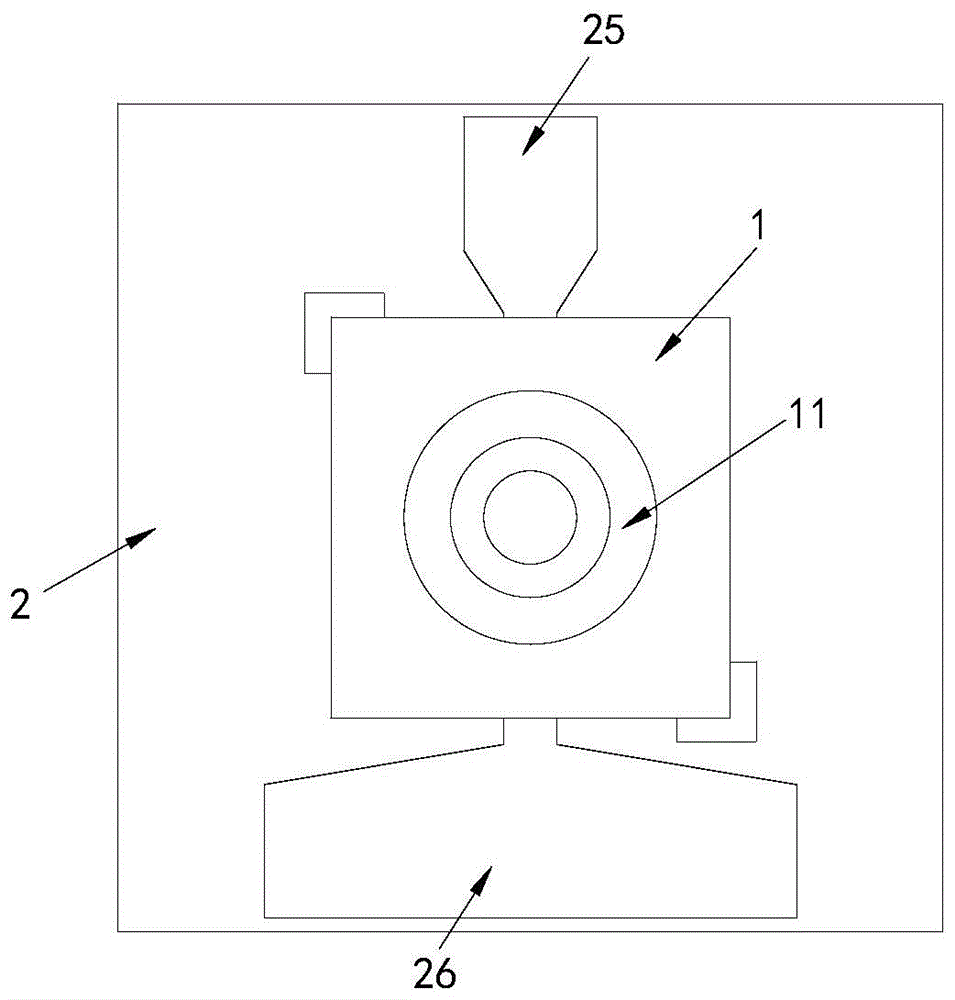

High-speed ingaas photodetector chip flip-chip integration structure and manufacturing method

A technology of photodetector and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., to achieve the effect of increasing the light receiving aperture, simple and applicable structural design, and reducing the influence of parasitic inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0048] As an implementation, the manufacturing process of the first metal pad, the second metal pad, the P electrode bonding pad and the N electrode bonding pad, that is, the P and N metal electrode patterns on the carrier includes: firstly adopt The magnetron sputtering method grows the TiW / Au metal film layer in sequence, with a thickness of 100nm / 500nm; and then adopts the photolithography lift-off process to define the evaporation area of the P and N metal electrodes on the sapphire substrate. Methods Thicken the Au layer to 3 microns; then remove the TiW / Au metal film layer outside the P and N metal electrode patterns by wet etching; finally complete the sapphire substrate with P and N metal electrode patterns. Specifically, on the sapphire substrate (thickness 250 microns), the TiW / Au metal film layer is sequentially grown by magnetron sputtering to form an initial seed (seed) layer, and the thickness requirement is 100 nanometers / 500 nanometers; Then use high-resoluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com