Biological modification method for inhibiting starch retrogradation

A technology of biomodification and starch, which is applied in food science, food preservation, application, etc., can solve the problems of increased branching of starch, achieve the effects of reducing hardness, improving digestibility, and inhibiting starch retrogradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

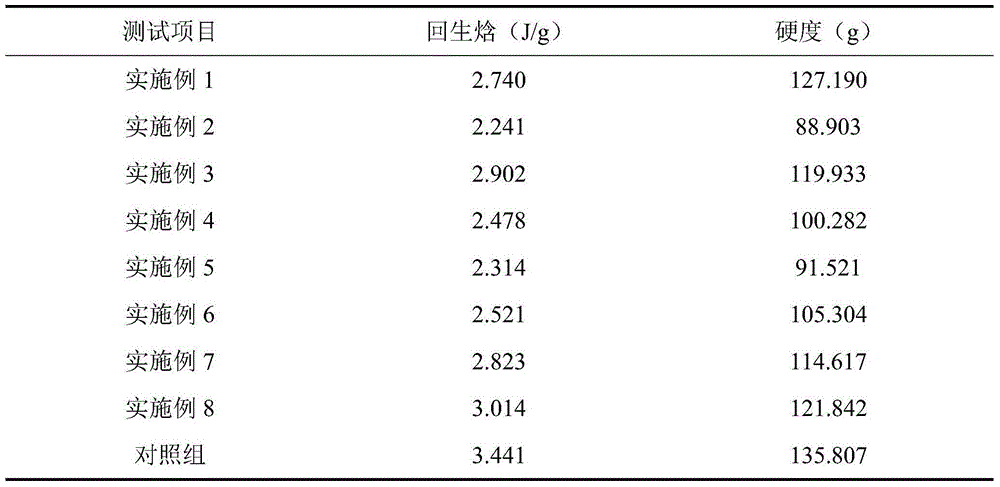

[0026] Dissolve cornstarch in 100mL water to obtain 30% (w / v) cornstarch milk, adjust the pH to 7.5 with 2.5% NaOH solution, add starch branching enzyme at 300U / g starch on a dry basis, and treat at 50°C for 4h, The reaction solution was washed with 5 times the volume of deionized water, the solid matter was collected, and vacuum-dried at 45° C. for 12 hours to obtain modified starch. Taking corn starch without starch branching enzyme treatment as a control, after refrigerated at 4°C for 7 days, the retrogradation enthalpy and hardness were compared, and the results are shown in Table 1.

Embodiment 2

[0028] Dissolve cornstarch in 100mL water to obtain 30% (w / v) cornstarch milk, adjust the pH to 7.5 with 2.5% NaOH solution, add starch branching enzyme at 300U / g starch on a dry basis, and treat at 50°C for 10h. The reaction solution was washed with 5 times the volume of deionized water, the solid matter was collected, and vacuum-dried at 45° C. for 12 hours to obtain modified starch. Taking corn starch without starch branching enzyme treatment as a control, after refrigerated at 4°C for 7 days, the retrogradation enthalpy and hardness were compared, and the results are shown in Table 1.

Embodiment 3

[0030] Dissolve cornstarch in 100mL water to obtain 30% (w / v) cornstarch milk, adjust the pH to 7.5 with 2.5% NaOH solution, add starch branching enzyme at 300U / g starch on a dry basis, and treat at 50°C for 6h, The reaction solution was washed with 5 times the volume of deionized water, the solid matter was collected, and vacuum-dried at 45° C. for 12 hours to obtain modified starch. Taking corn starch without starch branching enzyme treatment as a control, after refrigerated at 4°C for 7 days, the retrogradation enthalpy and hardness were compared, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com