Bone drill with stopping function

A bone drill and functional technology, which is applied in the field of bone drills with self-stop function, can solve the problems of increasing operation time and strength, reducing the service life of high-precision bone drills, and prolonging the time of patients in bed, so as to facilitate treatment and reduce medical treatment. Risk, effectiveness of reducing operational difficulty and risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

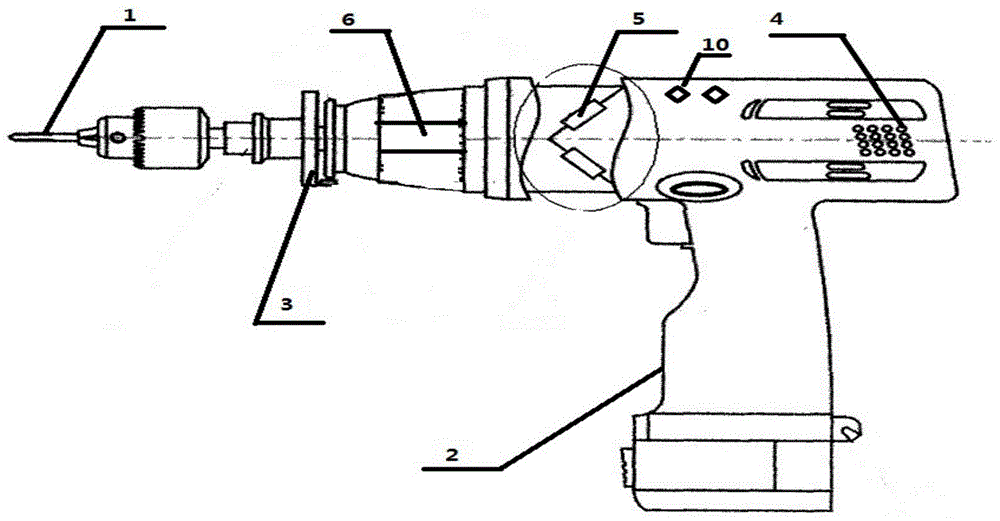

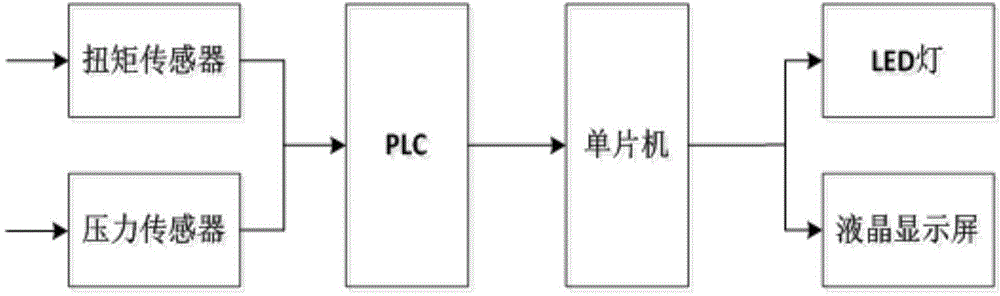

[0025] Such as figure 1 , 2 As shown, in a preferred embodiment of the present invention, the bone drill with self-pause function of the present invention includes a pressure sensor 6, a torque sensor 5, a PLC, a single-chip computer, a relay, an LED 10, a liquid crystal display, and a key board 4.

[0026] Among them, the pressure sensor 6 and the torque sensor 5 constitute the sensor module of the bone drill with self-stop function of the present invention, which is used to obtain the pressure and torque received by the drill bit 1 and to obtain the first electrical signal and the first electrical signal corresponding to the pressure and torque. The second electrical signal is output to the intelligent control module. In this embodiment, three strain gauges are arranged on the same section of the ring member of the motor 3, and the angle with the center axis of the ring member is ±60°, see figure 1 The position of the strain gauge drawn as a square in the circle at the middle to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com