Desulfurization device and desulfurization method

A desulfurization device, a square technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor combustion stability of boilers, unfavorable implementation, impact and damage of reaction gas flow balance, etc., to avoid insufficient desulfurization efficiency, The effect of improving the gas-solid separation efficiency and reducing the ash powder escape rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

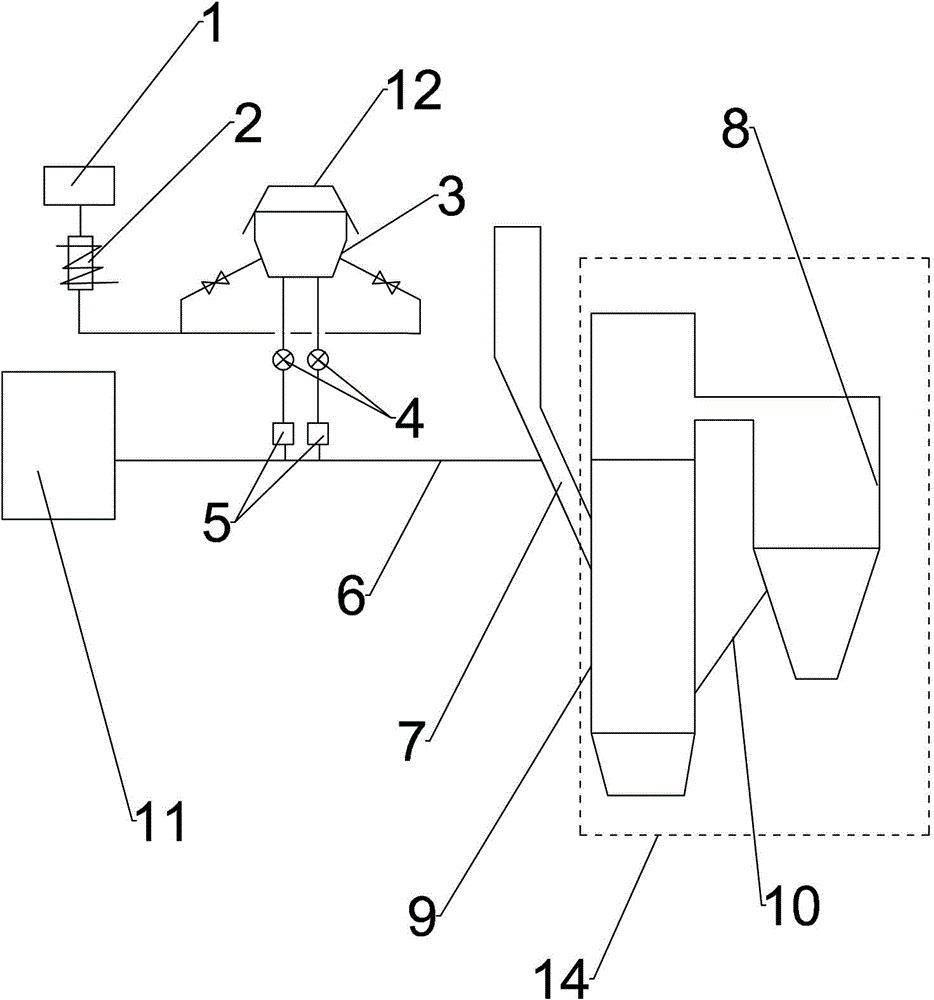

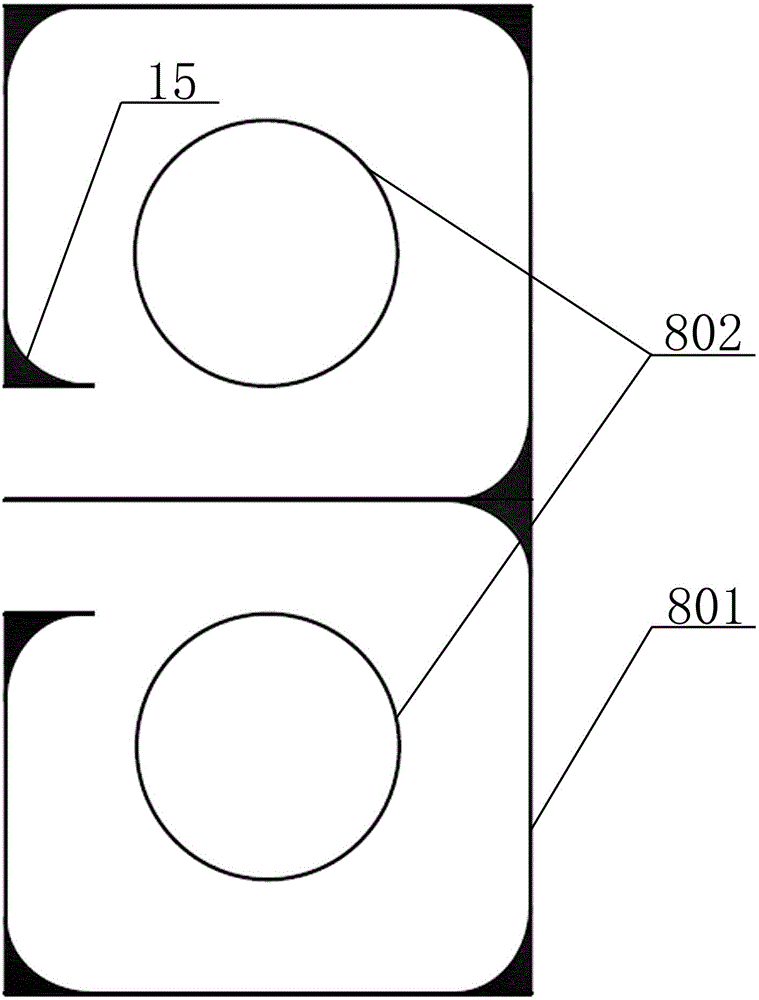

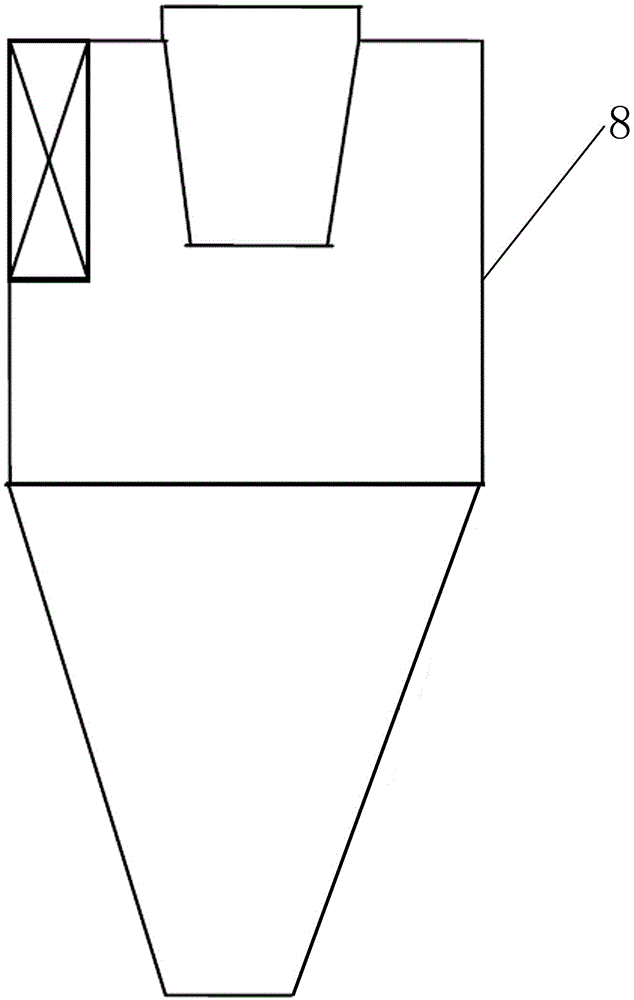

[0027] Such as figure 1 As shown in -5, a desulfurization device includes a fan 1, a limestone bin 3, a gas storage tank 11 and a circulating fluidized bed boiler 14, and the circulating fluidized bed boiler 14 includes a furnace 9, a return pipe 10 and a square separator 8, The upper part of the square separator 8 communicates with the upper part of the furnace 9; the inside and outside of the square separator 8 are respectively a central cylinder 802 and a square water cooling screen 801, the upper part of the central cylinder 802 is a cylindrical structure, and the lower part is a top-to-bottom The frustum of a cone structure that closes downwards (the diameter ratio of the upper and lower parts of the frustum of the cone structure is 10:7, and the height ratio of the upper and lower parts of the central tube is 1:7); the right-angled surfaces of the inner surface of the square water-cooling screen 801 are respectively fastened A wear-resistant material layer (made of corun...

Embodiment 2

[0033] The difference between the desulfurization device used in embodiment 2 and embodiment 1 is that: the angle between the feed pipe 4 and the coal drop pipe 7 is 50°, the diameter ratio of the upper and lower sides of the frustum of conical structure is 10:6, and the center The height ratio of the upper and lower parts of the cylinder is 1:10.

[0034] The desulfurization method in Example 2 is different from the desulfurization method used in Example 1 in that: keep the temperature inside the circulating fluidized bed boiler at 950°C, desulfurize and denitrify the coal fired; the S content of the incoming coal is 0.91% , the particle size of limestone is 1.5-2.5mm, the effective CaCO 3 The content is 60%, and the bulk density is 1.25t / m 3 , the conveying speed of limestone is 14m / s, the gas-solid ratio is 1:3, the original emission of flue gas is SO 2 Concentration 4137mg / m 3 , SO in flue gas emission after desulfurization 2 Concentration 82mg / m 3 , the achieved des...

Embodiment 3

[0038] The difference between the desulfurization device used in Example 3 and Example 1 is that the angle between the feed pipe 4 and the coal drop pipe 7 is 45°, the diameter ratio of the upper and lower sides of the frustum of conical structure is 10:8, and the center The height ratio of the upper and lower parts of the cylinder is 1:3.

[0039] The desulfurization method of embodiment 3 is different from the desulfurization method used in embodiment 1 in that: the temperature in the furnace 9 of the circulating fluidized bed boiler is kept at 900 ° C, and the coal is desulfurized and denitrified; the S content of the coal entering the furnace is 0.39%, the particle size of limestone is 1.5-2.5mm, and the bulk density is 1.2t / m 3 , effective CaCO 3 The content is 50%. The conveying speed of limestone is 14m / s, the gas-solid ratio is 1:6, and the original emission of SO 2 Concentration 2313mg / m 3 , SO in flue gas emission after desulfurization 2 Concentration 43mg / m 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com