Powder Manufacturing Equipment

A technology for manufacturing equipment and powder, which is applied in the field of powder manufacturing equipment, can solve problems such as difficult heating, uneven temperature distribution, and uneven thermal process, etc., and achieve the effect of suppressing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a powder manufacturing apparatus according to a first embodiment of the present invention will be described based on the drawings. In addition, in the following description, although terms indicating directions and positions (for example, "one end" and "another end", "upstream" and "downstream", etc.) are used for convenience, this is to make the invention easier to understand. The meanings of terms do not limit the technical scope of the present invention. In addition, the following description is merely an illustration of one embodiment of the present invention, and is not intended to limit the present invention and its application objects or uses.

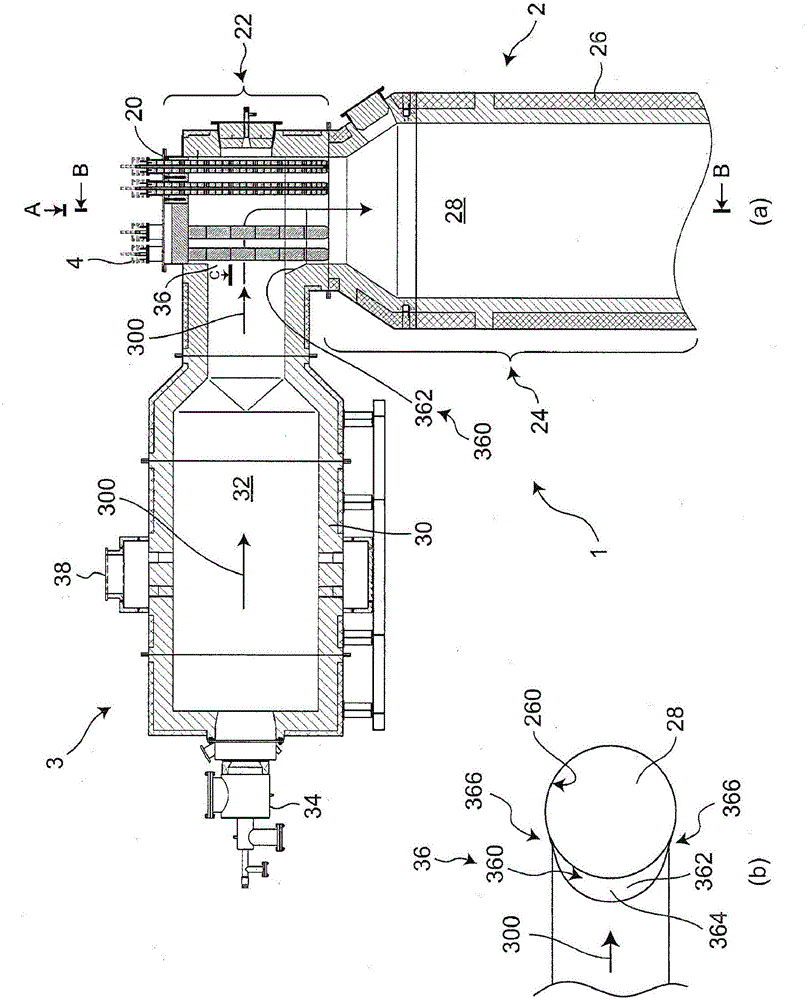

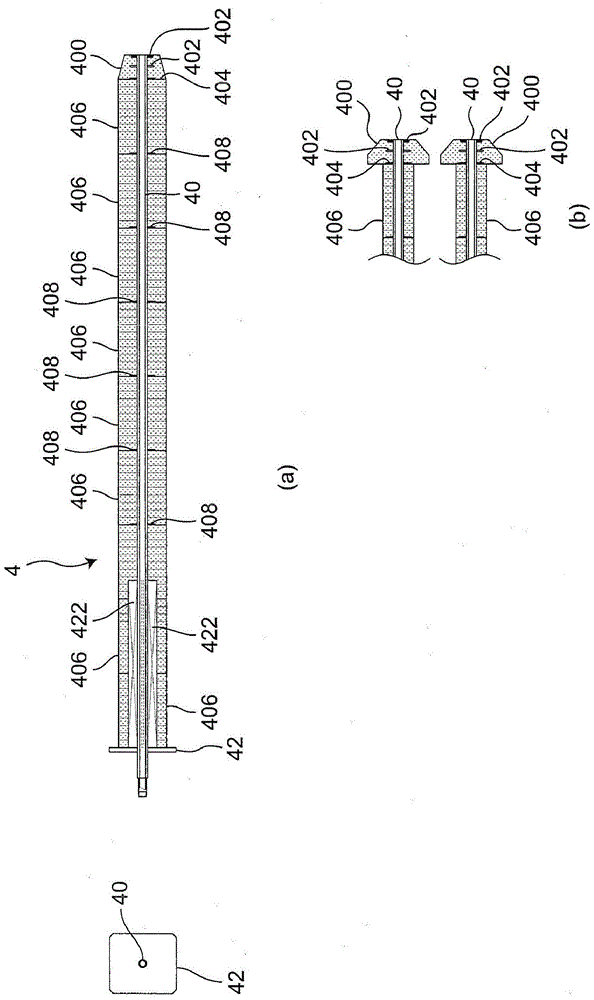

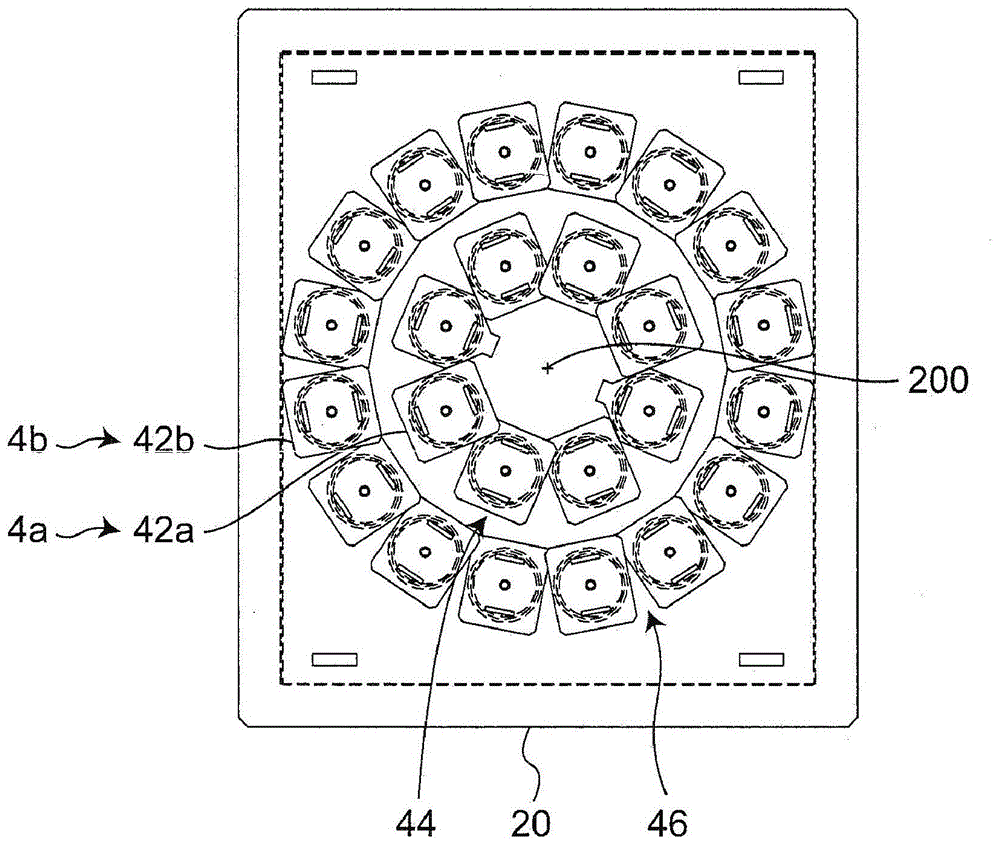

[0035] Such as figure 1 As shown in (a), the powder manufacturing device 1 includes a vertical cylindrical furnace 2, a horizontal cylindrical combustion device 3, and a raw material nozzle 4, and the raw material nozzle 4 is arranged vertically downward in the vertical furnace 2. The top 20 of the furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com