Composite photocatalyst-In2O3/CNB and preparation method and application thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problems of low catalytic efficiency, limited application, and unsatisfactory photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1In

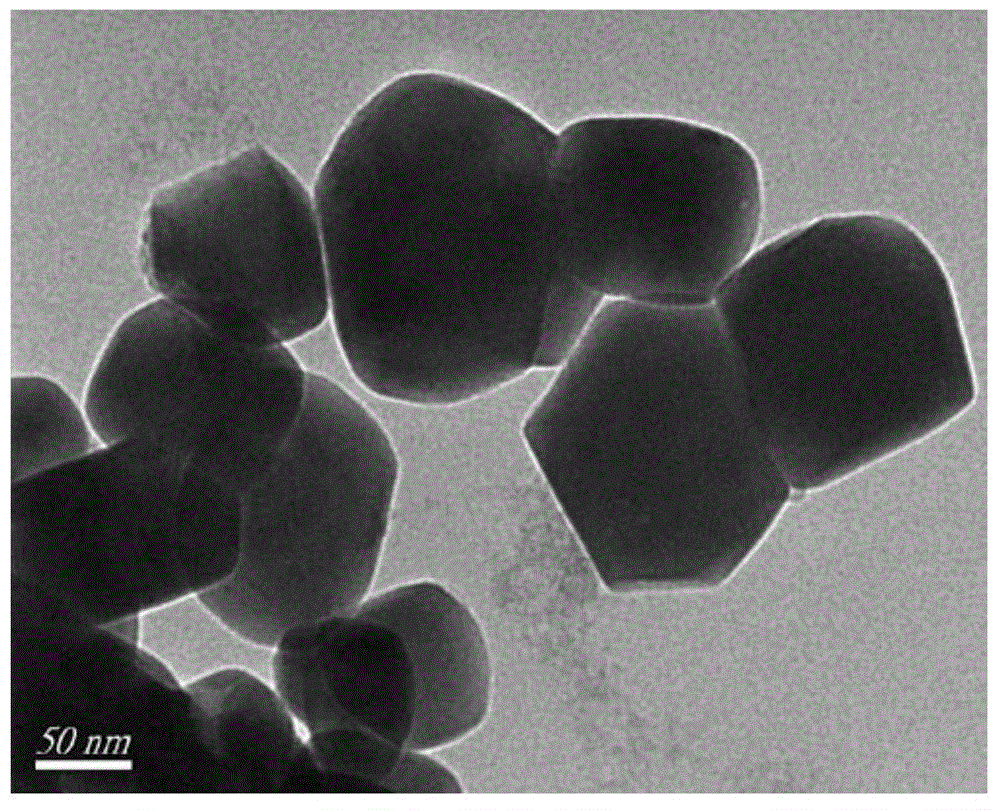

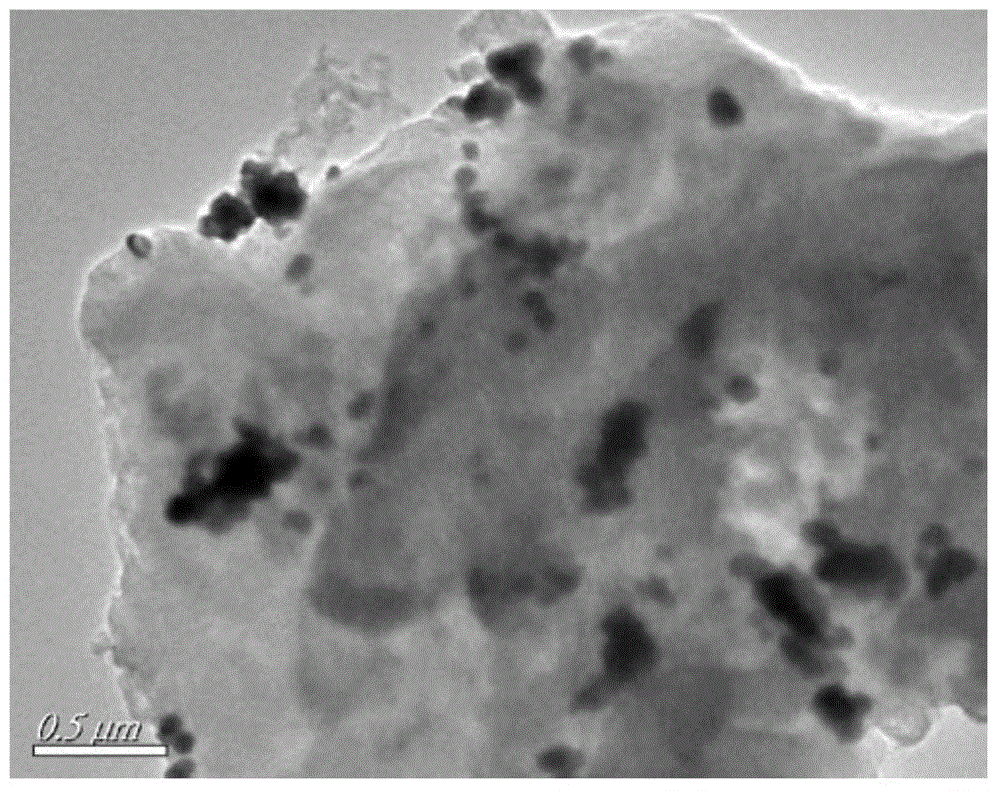

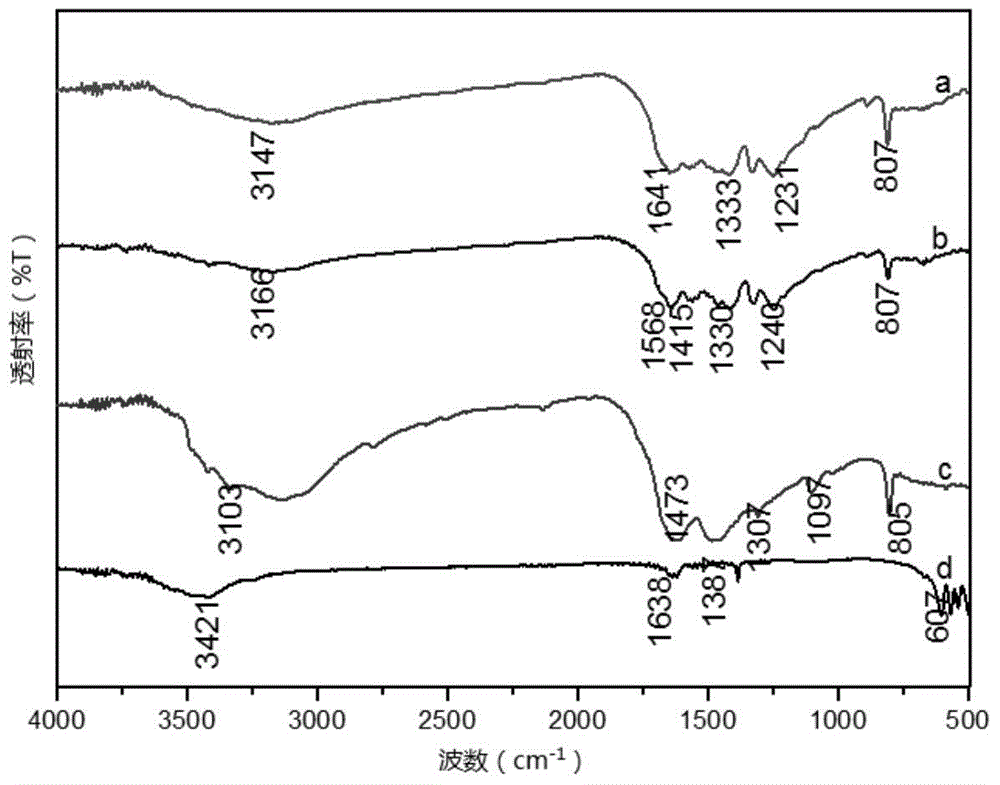

[0079] Example 1In 2 O 3 Preparation of / CNB (0.01)

[0080] (1) Weigh 1.0g cyanamide and 50.0mg boron oxide respectively, dissolve them in water after mixing, remove the water in the mixture at 120°C, and calcinate the solid obtained after removing the solvent water at 400°C for 1 hour, Cooling to obtain CNB;

[0081] (2) Weigh the product CNB 1.0g and 0.01g In 2 o 3 , mixed and ground, calcined and cooled at 900 °C to obtain the composite photocatalyst In 2 o 3 / CNB.

Embodiment 2In

[0082] Example 2In 2 O 3 Preparation of / CNB (0.05)

[0083] (1) Weigh 3.0g of dicyandiamide and 0.5mg of boric acid respectively, dissolve them in water after mixing, remove the water in the mixture at 100°C, and calcinate the solid obtained after removing the solvent water at 800°C for 5 hours, Cooling to obtain CNB;

[0084] (2) Weigh the product CNB1.0g and 0.05g In 2 o 3 , mixed and ground, calcined and cooled at 300 °C to obtain the composite photocatalyst In 2 o 3 / CNB.

Embodiment 3In

[0085] Example 3In 2 O 3 Preparation of / CNB (0.1)

[0086] (1) Weigh 10.0g melamine and 20.0mg sodium tetraphenylborate respectively, mix them and dissolve them in water, remove the water in the mixture at 80°C, and calcinate the solid obtained after removing the solvent water at 550°C for 4 hours , cooled to obtain CNB;

[0087] (2) Weigh the product CNB1.0g and 0.10g In 2 o 3 , mixed and ground, calcined and cooled at 400 °C to obtain the composite photocatalyst In 2 o 3 / CNB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com