Preparation method and application of magnetic Cu-MOF-based photocatalyst

A photocatalyst and magnetic technology, applied in the field of photocatalytic materials, can solve problems such as low utilization rate of visible light, easy agglomeration failure, heavy metal pollution, etc., and achieve good photocatalytic degradation efficiency, easy recycling, and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] triangular organic ligand H 3 The preparation method of L specifically follows the steps:

[0036]Step a, dissolving 4-amino-2-methylbenzoic acid in DMF, and continuously magnetic stirring in an ice-water bath until completely dissolved to obtain a mixed solution;

[0037] Every 1mol of 4-amino-2-methylbenzoic acid corresponds to 65mL of DMF;

[0038] Step b, dissolve trimesoyl chloride in DMF, stir until dissolved, and slowly add dropwise to the mixture in step a within 15 minutes, then add triethylamine dropwise within 10 minutes, react in an ice-water bath for 3 hours, and then React at room temperature for 24h to obtain a reaction solution;

[0039] Every 1mol of trimesoyl chloride corresponds to 100mL of DMF and 0.36mol of triethylamine

[0040] Step c, adding distilled water to the reaction solution under continuous magnetic stirring, and removing DMF and distilled water with a Buchner funnel after 30 min under reduced pressure suction filtration, that is, wash...

Embodiment 1

[0051] The organic ligand H 3 L (0.04mmol, 24.44mg), Cu(NO 3 ) 2 ·3H 2 O (0.08mmol, 14.36mg), piperazine hexahydrate (0.008mmol, 1.56mg) and 0.04mmol (9.26mg) Fe 3 o 4 , in 8.0mL of N,N-dimethylformamide and absolute ethanol mixed solution (volume ratio is 5:3), after uniform mixing, dropwise add a concentrated nitric acid solution with a mass fraction of 65%, to adjust the reaction system The pH value is 5.0, and it is sealed in a 25mL vial. Solvothermal reaction was carried out at 75 °C for 48 h, and then cooled to room temperature naturally to obtain the magnetic Cu-MOF-based photocatalyst.

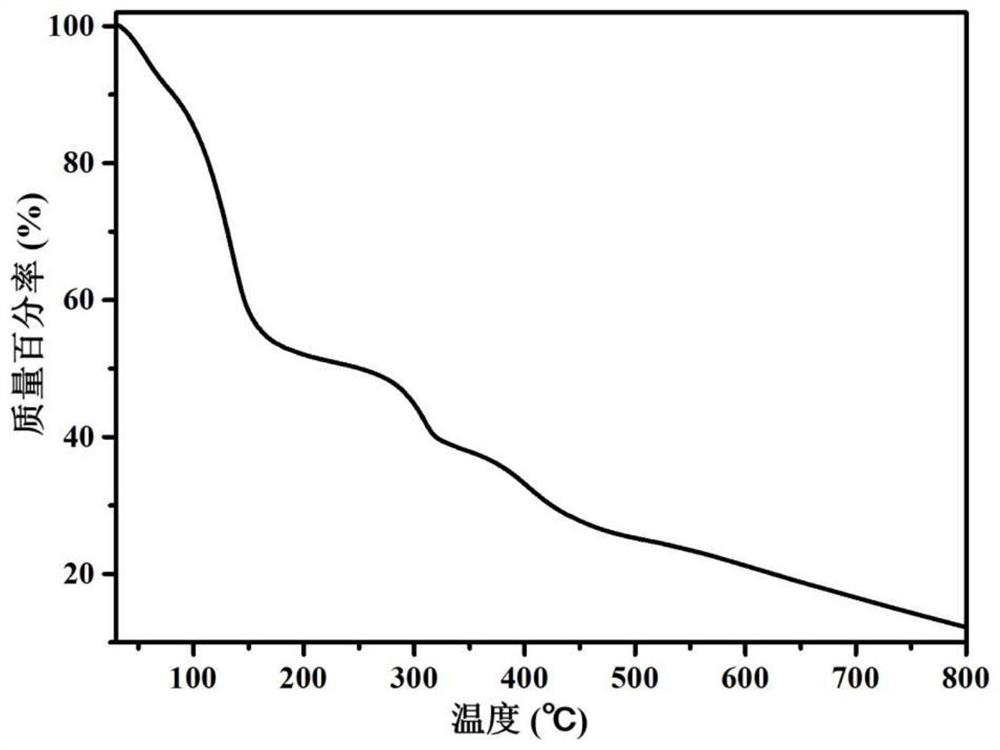

[0052] figure 1 It is the thermal weight loss curve of the prepared magnetic Cu-MOF-based photocatalyst. It can be seen from the figure that the magnetic Cu-MOF-based photocatalyst in the range of 30-800℃ has experienced two The main weight loss stage; about 47.63% weight loss rate between 30-190 °C, from the departure of small guest molecules and coordinated DMF molecules in th...

Embodiment 2

[0063] The preparation method of a kind of magnetic Cu-MOF based photocatalyst of the present invention is specifically:

[0064] Under closed conditions, copper nitrate trihydrate Cu(NO 3 ) 2 ·3H 2 O and organic ligand H 3 L. Fe 3 o 4 Mix magnetic nanoparticles, template agent piperazine hexahydrate, N,N-dimethylformamide and absolute ethanol evenly, keep stirring, and add concentrated nitric acid solution dropwise to adjust the pH of the reaction system to 4.0, under solvothermal conditions Reaction, obtain above-mentioned magnetic Cu-MOF base photocatalyst;

[0065] Copper nitrate trihydrate, organic ligand H 3 L, piperazine hexahydrate and Fe 3 o 4 The molar ratio of nanoparticles is 2:1:0.2:1; the volume ratio of N,N-dimethylformamide and absolute ethanol is 5:1; the mass fraction of concentrated nitric acid solution is 65%; the temperature of solvothermal reaction 65°C, the required reaction time is 24 hours;

[0066] triangular organic ligand H 3 The preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com