In-MOF material based on tricarboxylic acid ligand as well as preparation method and application of In-MOF material

A technology of tricarboxylic acids and ligands, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc. For problems such as easy closure, it can achieve the effects of good photocatalytic degradation efficiency, easy recyclability and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] organic ligand H 3 The preparation method of L specifically follows the steps:

[0057] Step a, dissolving 4-amino-2-methylbenzoic acid in DMF, and continuously magnetic stirring in an ice-water bath until completely dissolved to obtain a mixed solution;

[0058] Every 1mol of 4-amino-2-methylbenzoic acid corresponds to 65mL of DMF;

[0059] Step b, dissolve trimesoyl chloride in DMF, stir until dissolved, and slowly add dropwise to the mixture in step a within 15 minutes, then add triethylamine dropwise within 10 minutes, react in an ice-water bath for 3 hours, and then React at room temperature for 24h to obtain a reaction solution;

[0060] Every 1mol of trimesoyl chloride corresponds to 100mL of DMF and 0.36mol of triethylamine

[0061] Step c, adding distilled water to the reaction solution under continuous magnetic stirring, and removing DMF and distilled water with a Buchner funnel after 30 min under reduced pressure suction filtration, that is, washing with d...

Embodiment 1

[0065] The organic ligand H 3 L (0.02mmol, 12.22mg), In(NO 3 ) 2 ·3H 2 O (0.04mmol, 12.75mg) and hexamethylenetetramine (0.004mmol, 0.56mg) were mixed in 6.5mL of N,N-dimethylformamide, and concentrated nitric acid with a mass fraction of 65% was added dropwise solution, adjust the pH value of the reaction system to 5.0, and seal it in a 25mL small glass bottle. The solvothermal reaction was carried out at 115°C for 72 hours, and then naturally cooled to room temperature to obtain a colorless and transparent long In-MOF material.

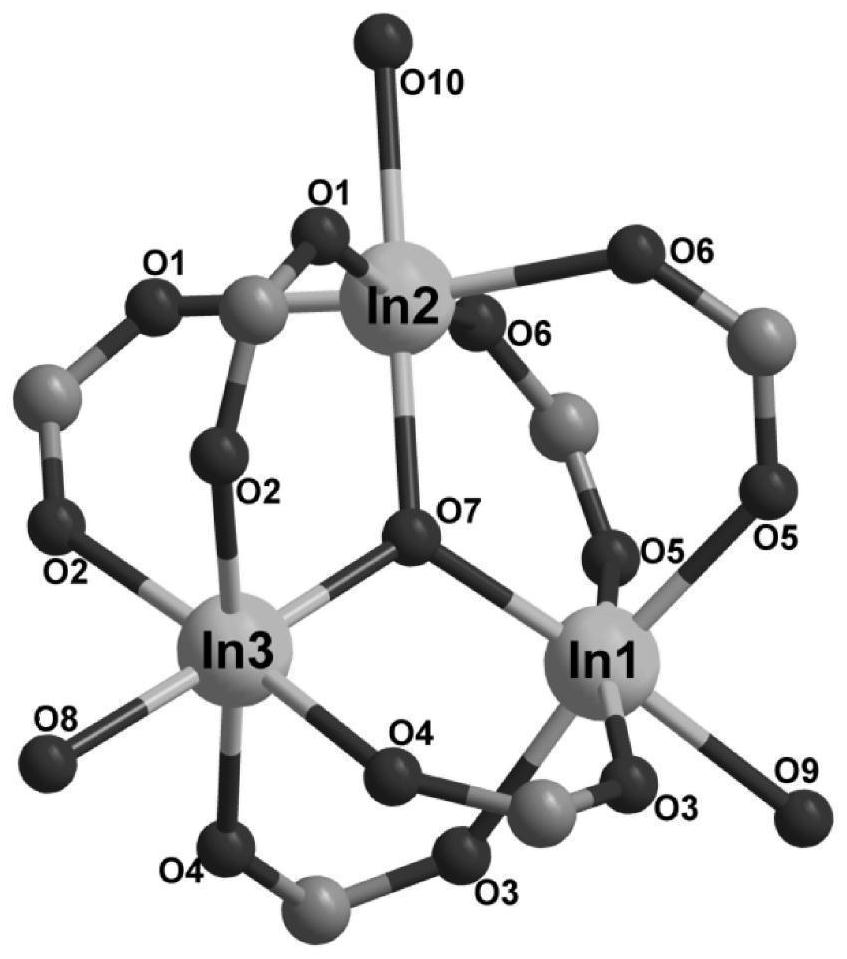

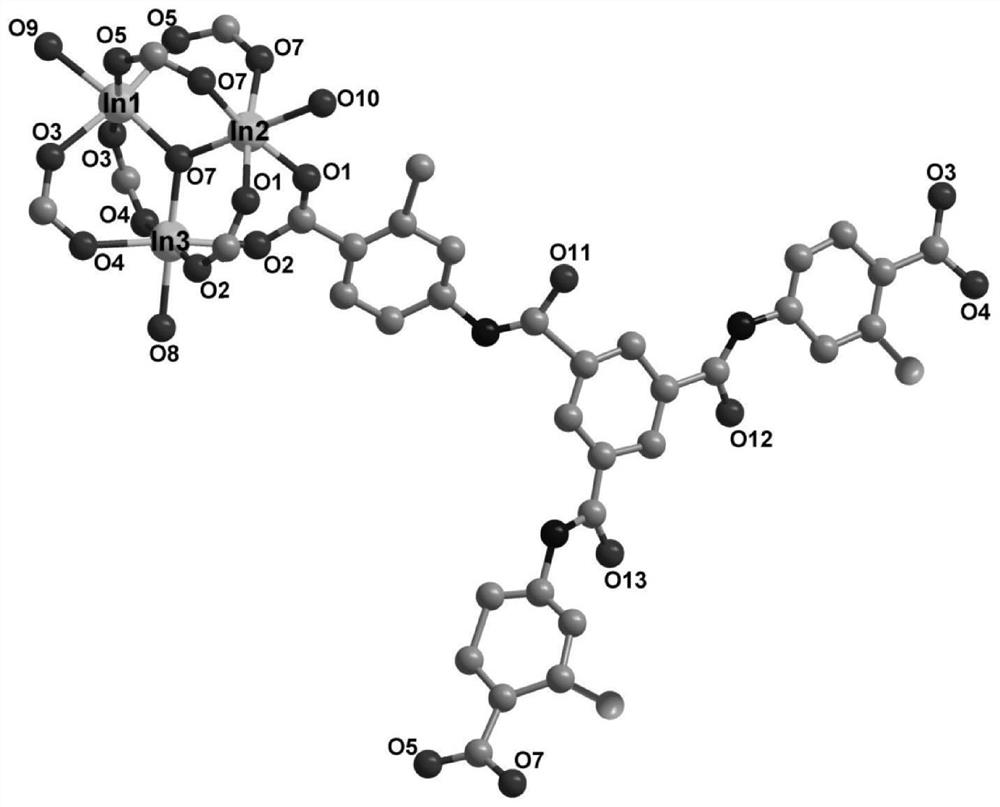

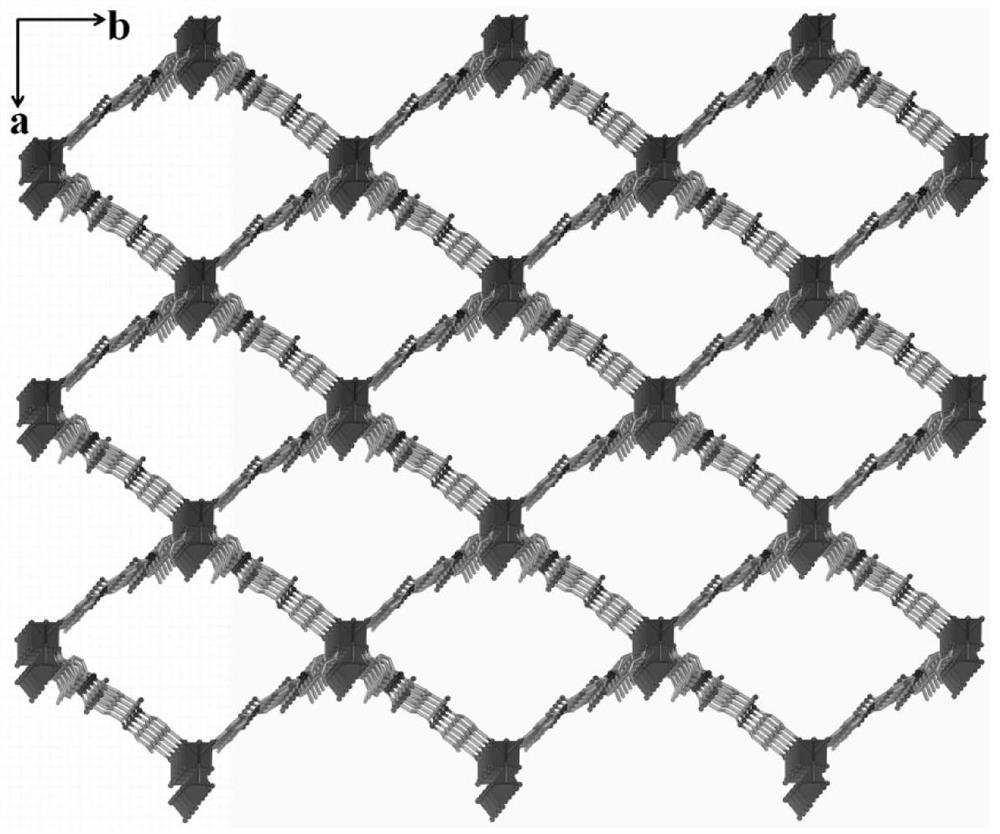

[0066] The method for testing the crystal structure of the In-MOF material obtained in the above examples is the same as the structure, see the following for details:

[0067] Determination of the crystal structure:

[0068] Select a single crystal of the transparent and crack-free In-MOF material, and use the Bruker Aper II CCD single crystal X-ray diffractometer of Bruker, Germany at room temperature (about 296K) to perform single crystal str...

Embodiment 2

[0085] A method for preparing an In-MOF material based on a tribasic carboxylic acid ligand, specifically:

[0086] Under closed conditions, indium nitrate trihydrate In(NO 3 ) 2 ·3H 2 O and organic ligand H 3 L. The template agent hexamethylenetetramine is dissolved in N,N-dimethylformamide, and concentrated nitric acid solution is added dropwise to adjust the pH of the reaction system to 4.0, and react under solvothermal conditions to obtain the above crystal structure In-MOF materials.

[0087] The temperature of the solvothermal reaction is 100°C, and the required reaction time is 72 hours;

[0088] Indium nitrate trihydrate, organic ligand H 3 L. The molar ratio of hexamethylenetetramine and N,N-dimethylformamide is 2:1:0.2:300; the mass fraction of concentrated nitric acid solution is 65%;

[0089] organic ligand H 3 The preparation method of L specifically follows the steps:

[0090] Step a, dissolving 4-amino-2-methylbenzoic acid in DMF, and continuously magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com