Preparation method of high-performance titanium dioxide photocatalyst

A titanium dioxide and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of weak chemical stability and poor activity, and achieve improved photocatalytic activity and charge mobility, good photocatalytic degradation efficiency, good photocatalytic activity and photocatalytic stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

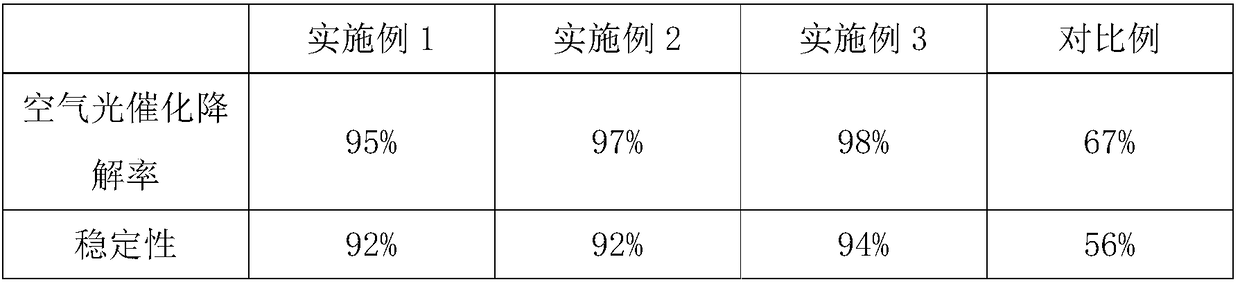

Examples

Embodiment 1

[0033] A kind of preparation method of high-performance titanium dioxide photocatalyst, comprises the steps:

[0034] Step 1, adding n-butyl titanate to absolute ethanol, then adding polyvinylpyrrolidone, and ultrasonically dispersing to obtain a titanium alcohol dispersion;

[0035] Step 2, adding the titanic acid dispersion into a vacuum reaction kettle for vacuum distillation for 60 minutes to obtain a titanium slurry;

[0036] Step 3, adding tourmaline powder into the titanium slurry and stirring evenly, then adding it to a ball milling reactor for constant temperature ball milling for 20 minutes to obtain a mixed dry powder;

[0037] Step 4, adding the mixed dry powder into the reaction kettle to pressurize and keep the temperature for 1 hour, and then quickly release the pressure and lower the temperature to obtain the prefabricated powder;

[0038] In step 5, the prefabricated powder is added to absolute ethanol for washing, filtered and then dried to obtain a high-per...

Embodiment 2

[0049] A kind of preparation method of high-performance titanium dioxide photocatalyst, comprises the steps:

[0050] Step 1, adding n-butyl titanate to absolute ethanol, then adding polyvinylpyrrolidone, and ultrasonically dispersing to obtain a titanium alcohol dispersion;

[0051] Step 2, adding the titanic acid dispersion into a vacuum reactor for vacuum distillation for 90 minutes to obtain a titanium slurry;

[0052] Step 3, adding tourmaline powder into the titanium slurry and stirring evenly, then adding it into a ball milling reactor for constant temperature ball milling for 30 minutes to obtain a mixed dry powder;

[0053] Step 4, adding the mixed dry powder into the reaction kettle to pressurize and keep the temperature for 3 hours, and then quickly release the pressure and lower the temperature to obtain the prefabricated powder;

[0054] In step 5, the prefabricated powder is added to absolute ethanol for washing, filtered and then dried to obtain a high-performa...

Embodiment 3

[0065] A kind of preparation method of high-performance titanium dioxide photocatalyst, comprises the steps:

[0066] Step 1, adding n-butyl titanate to absolute ethanol, then adding polyvinylpyrrolidone, and ultrasonically dispersing to obtain a titanium alcohol dispersion;

[0067] Step 2, adding the titanic acid dispersion into a vacuum reaction kettle for vacuum distillation for 80 minutes to obtain a titanium slurry;

[0068] Step 3, adding tourmaline powder into the titanium slurry and stirring evenly, then adding it into a ball milling reactor for constant temperature ball milling for 25 minutes to obtain a mixed dry powder;

[0069] Step 4, adding the mixed dry powder into the reaction kettle to pressurize and keep the temperature for 2 hours, and then quickly release the pressure and lower the temperature to obtain the prefabricated powder;

[0070] In step 5, the prefabricated powder is added to absolute ethanol for washing, filtered and then dried to obtain a high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com