Pass design method for producing seamless steel tubes by utilizing five-rack continuous rolling mill

A technology for seamless steel pipe and pass design, which is applied in rolling mill control devices, metal rolling, metal rolling, etc. It can solve the problem of not considering the metal flow rate, affecting the mechanical properties, geometric dimensions and residual stress of the pipe, and a large amount of calculation. And other issues

Active Publication Date: 2015-04-29

重庆万创无缝钢管制造有限公司

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] It is obvious that it is difficult to obtain the optimized result by empirically designing the roll pass; the calculation amount of the computer optimization design method is large, and the metal flow velocity is not considered, so the mechanical properties, geometric dimensions and residual stress of the pipe are affected.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 2

[0222] Tube blank diameter: 430 Blank tube diameter: 383 Rack number: 5

[0223]

[0224] Diameter reduction γ i

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

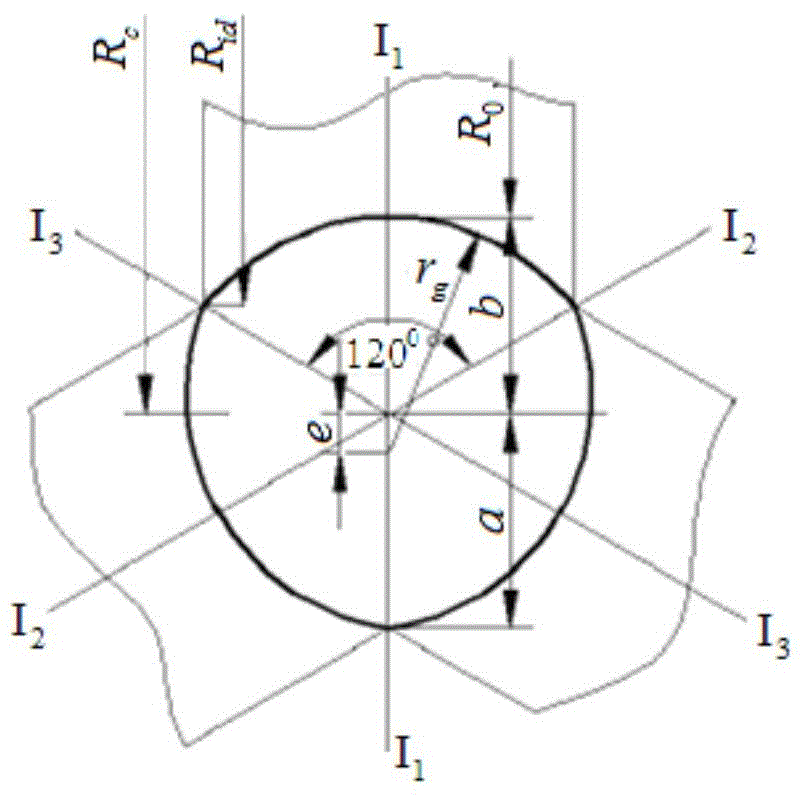

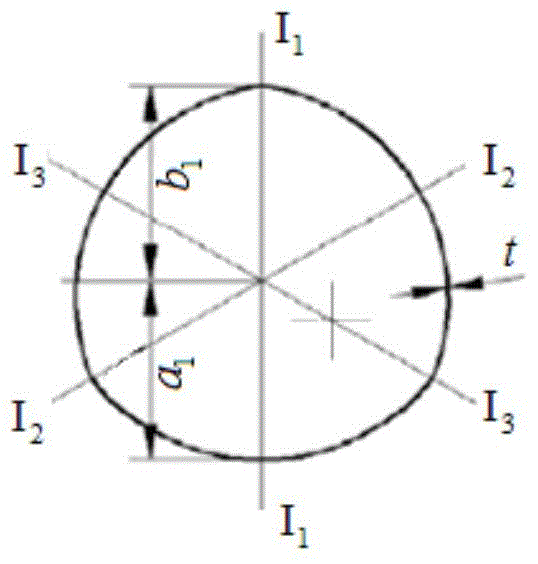

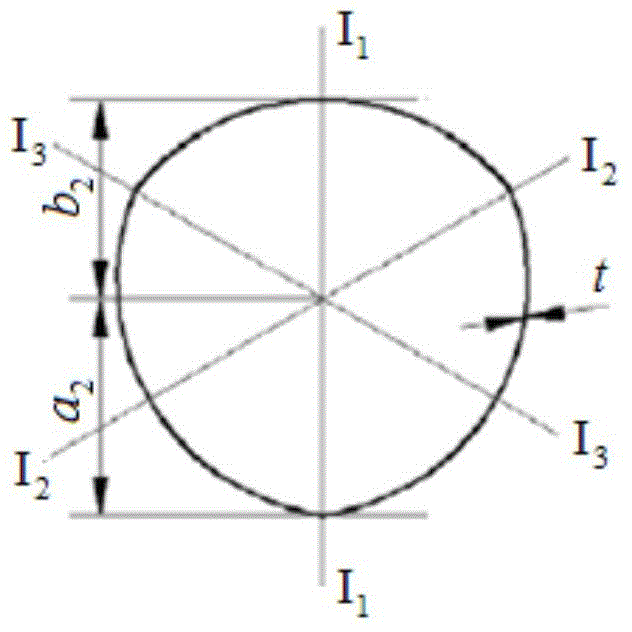

The invention discloses a pass design method for producing seamless tubes by utilizing a five-rack continuous rolling mill. The pass design method comprises the steps of determining the total diameter reduction rate of a continuous rolling mill set, and distributing diameter reduction rates of all racks; then, sequentially calculating pass parameters of each rack; calculating the diameter of a billet tube at the outlet end of each rack; calculating the distance from the pass axis of a roll at the roll outlet side of the continuous rolling mill to the bottom of a pass groove, the distance from the pass axis of a roll at the roll outlet side to the top of the pass groove and the arc radius of roll passes; calculating the ellipticity of each roll pass, calculating the length of each distribution curve, regulating and controlling the ellipticity of a second rack and a third rack within a 10% range, increasing by 1% every time, and finding out the length of the distribution curve with the smallest ellipticity; changing the position of a contact point, which is in contact with the billet tube, of the roll in a rolling deformation area, changing the position within a + / -15% range, increasing by 1% every time, calculating a group of contact arc length values, and obtaining a minimum value of a contact arc length differential value; calculating a longitudinal-horizontal flowing speed ratio of metal deformation of the billet tube. According to the method disclosed by the invention, the mechanical performance of products can be ensured.

Description

technical field [0001] The invention relates to the technical field of steel rolling, in particular to a pass design method for producing seamless steel pipes using a seven-stand continuous rolling mill. Background technique [0002] Seamless steel pipe is a kind of economic cross-section steel, which is widely used in the manufacture of structural parts and mechanical parts, and is widely used as a pipeline for transporting fluids such as oil, natural gas, gas and water. With the development of science and technology, the user's requirements for the quality of seamless steel pipes are constantly improving. The mechanical properties and shape error control of seamless steel pipes have become the main indicators for measuring product quality, which prompts enterprises to continue to pay attention to the mechanical properties and shape errors of products. Develop advanced production equipment and technology. [0003] In the production process of seamless steel pipes, the roll...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B37/78

CPCB21B37/78B21B2265/22

Inventor 李连进王惠斌王明贤张海军宗卫兵李牧丛萌

Owner 重庆万创无缝钢管制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com