Directional solidification device for multi-spoke aluminum alloy wheel

A technology of directional solidification and aluminum alloy, which is applied in metal processing equipment, casting molding equipment, casting molds, etc., can solve the problems of low product yield, more aluminum solution, and heavy blank weight, etc., and achieve high stability, stable production, The effect of high casting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

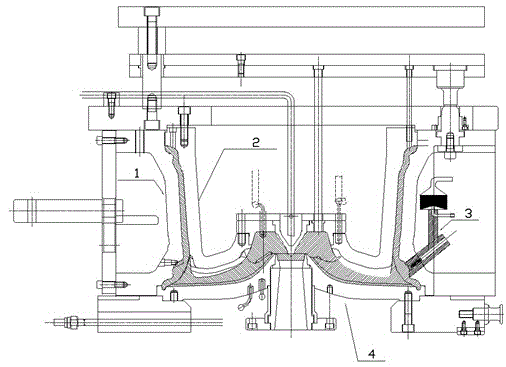

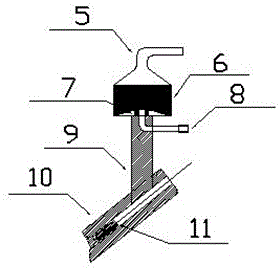

[0011] Such as figure 1 847-2210 shown is a ten-spoke aluminum alloy wheel directional solidification device, which includes a side mold 1, a top mold 2, a cooler 3, and a bottom mold 4. The cooler consists of a directional exhaust hood 5, a cylindrical louver heat sink 6. Connecting plug 7, air inlet duct 8, heat conduction copper rod 9, cooling rod 10 and thermocouple 11. Drill 10 holes with a diameter of 25mm in the area corresponding to the cavity of side mold 1 where there are hot nodes that are difficult to directional solidify, and assemble 10 coolers 3 in the corresponding holes of side mold 1; cylindrical louver fins 6 adopt heat dissipation Made of LF21 anti-rust aluminum alloy with good anti-rust performance, the directional exhaust cover 5 is wrapped on the cylindrical louver heat sink 6, and the directional exhaust cover 5 can discharge the heat of the louver heat sink 6 according to the set direction. The discharge process does not affect the non-thermal node a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com