A kind of lathe with dust removal assembly

A technology of dust removal components and lathes, which is applied in the field of machine tools, can solve the problems of blowing everywhere, debris is not easy to control, and dust removal effect is not good, so as to achieve the effect of convenient fixing, convenient dust collection and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

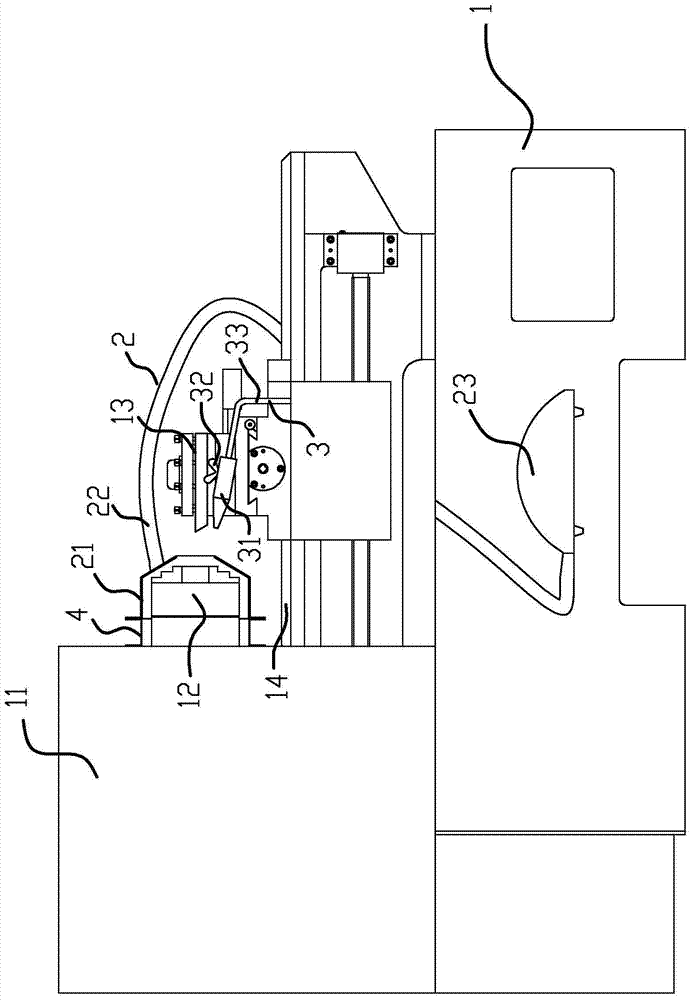

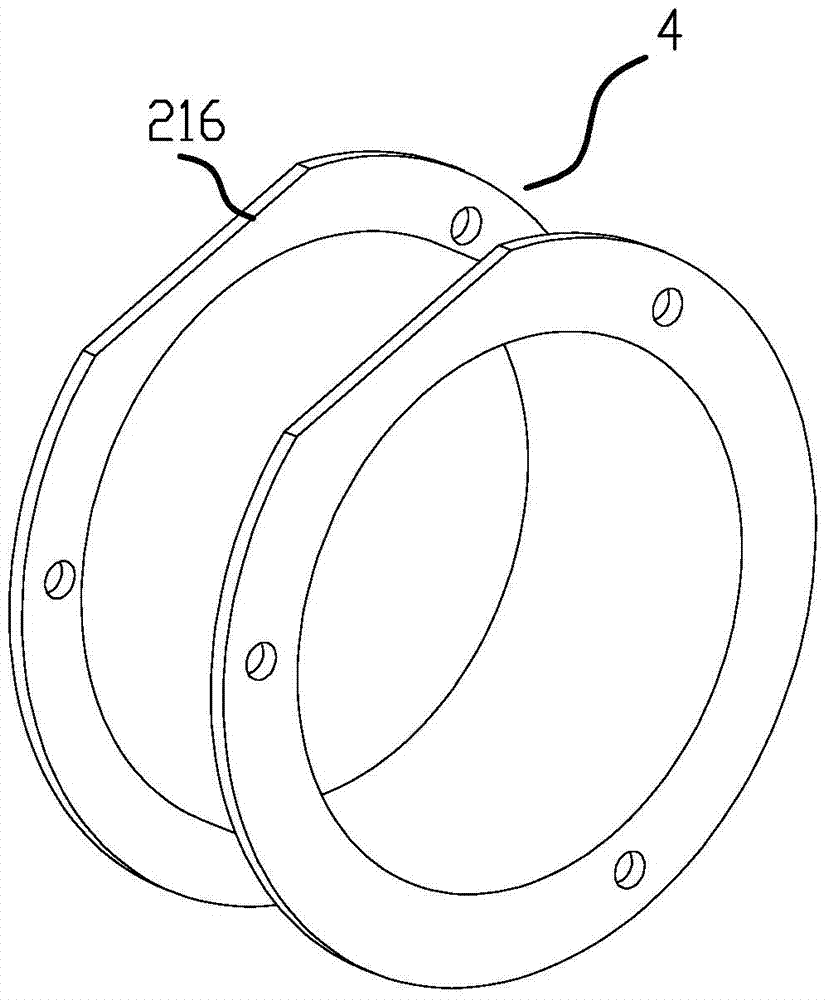

[0028] Such as figure 1 As shown, the lathe with the dust removal assembly includes a frame 1, a headstock 11 installed on the frame 1 and a tool rest assembly 13 slidingly arranged on the frame 1, and an automatic chuck is installed on the headstock 11 12. The automatic chuck 12 is connected to the spindle assembly on the bedside box 11. The automatic chuck 12 can clamp or loosen the workpiece. The spindle assembly can drive the automatic chuck 12 to rotate. A dust removal assembly is also installed on the frame 1 2. The dust removal assembly 2 includes a dust cover 21, a dust suction pipe 22 installed on the dust cover 21 and a vacuum cleaner 23 connected to the dust suction pipe 22. The dust suction pipe 22 is a round p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com