Single-point multi-view meter-hanging posture error detecting method of mobile industrial robot

An industrial robot and error detection technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems that affect the grasping and placing accuracy of manipulators, the position error of edge workpieces, and the accuracy of grasping and placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

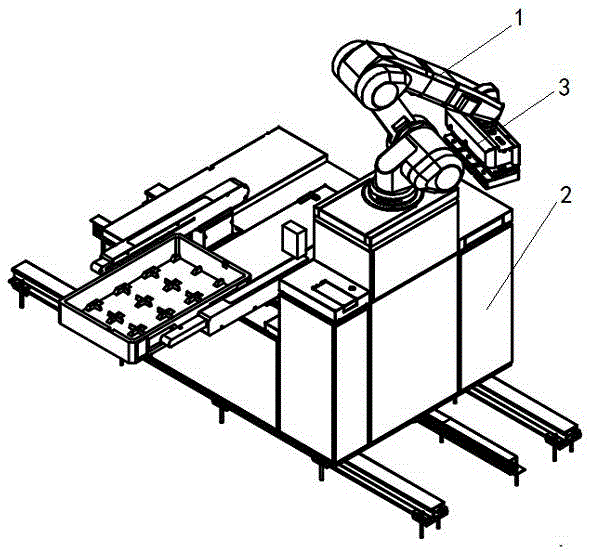

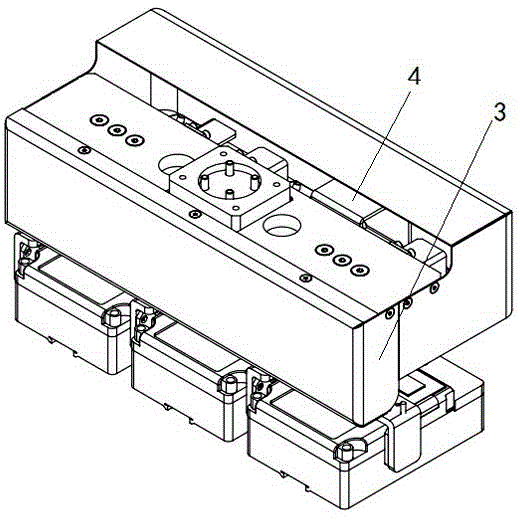

[0023] like figure 1 As shown, the mobile industrial robot 1 is guided by the AGV or RGV2, and the programming of the pick-and-place operation is realized through the teaching method. Since the base of the robot is not fixed, it is easy to be disturbed by the outside world, and the position reached by the end effector 3 is not exactly It is the teaching position, which affects the pick-and-place accuracy. The present invention determines the position error and the attitude angle error through a single-point multi-view method, so as to minimize the compensation of the attitude error caused by the mobile platform or other external uncertain factors. like figure 2 As shown, the end effector 3 is installed on the flange of the mobile industrial robot 1, and the camera 4 is installed at the end of the mobile industrial robot 1. Such a struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com