External protection system for silicon cutting machine tool

A protection system, silicon cutting technology, applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problems of inconvenient installation and operation, laborious opening and closing of doors, and large protective body, so as to achieve the effect of convenient observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Note: The direction word "front" proposed in this paper refers to the end of the machining area of the machine tool, that is, the front of the axial direction of the spindle, "rear" is the opposite end to "front", and "left" and "right" are the main Left and right in the view.

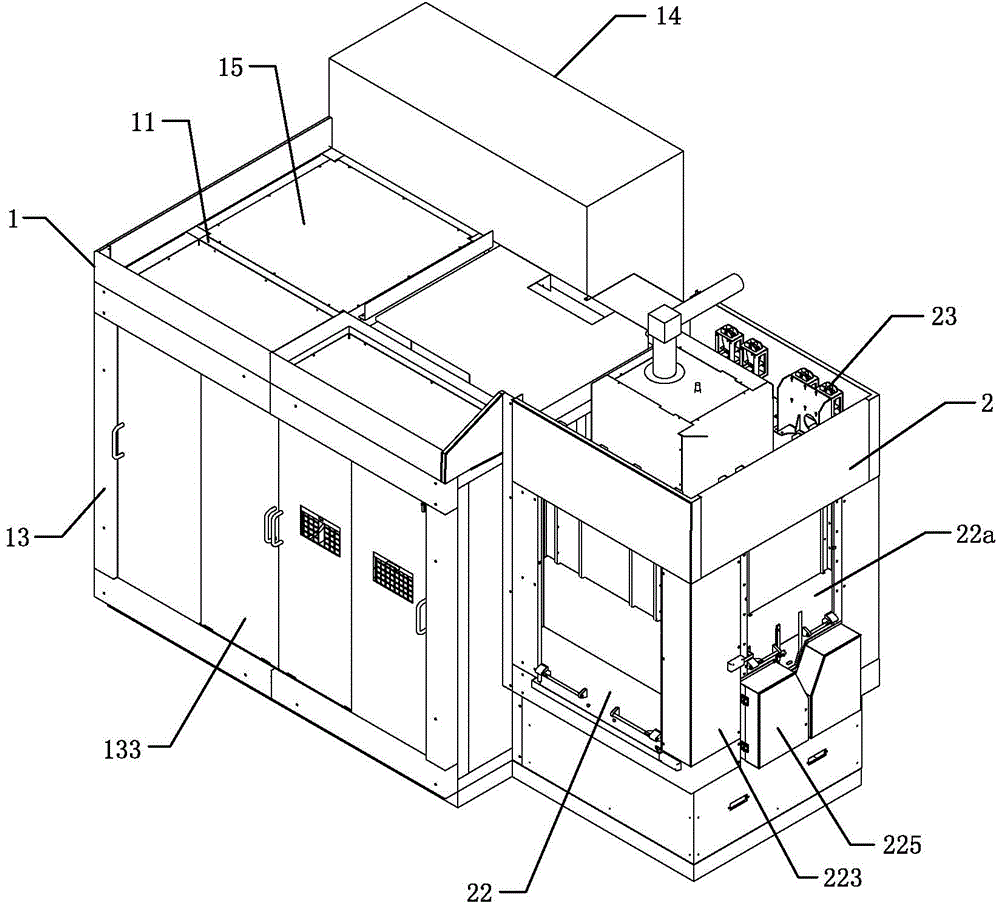

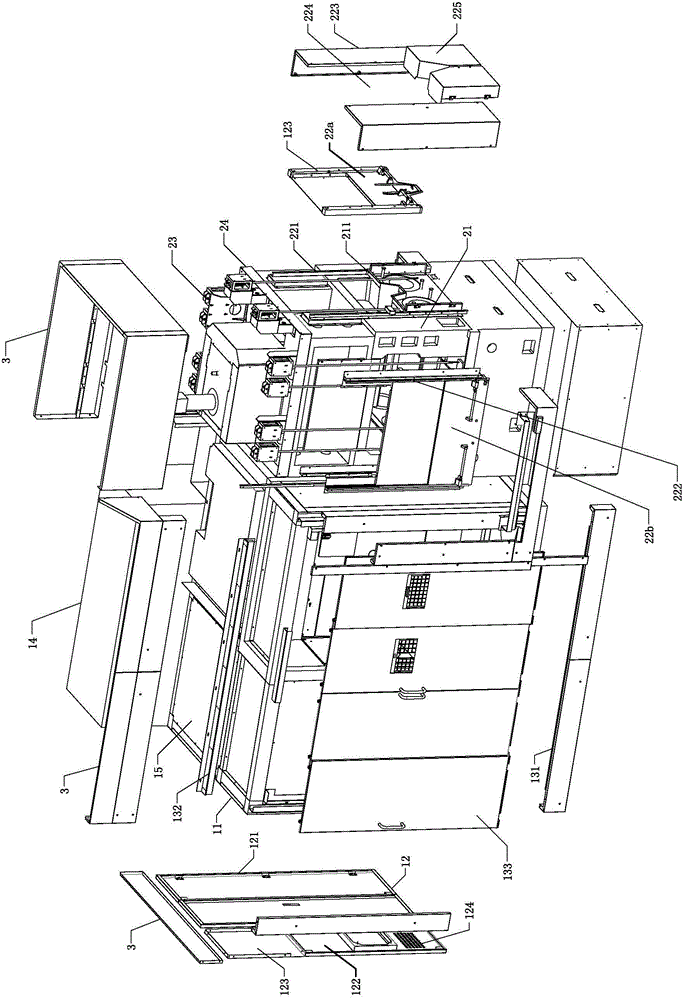

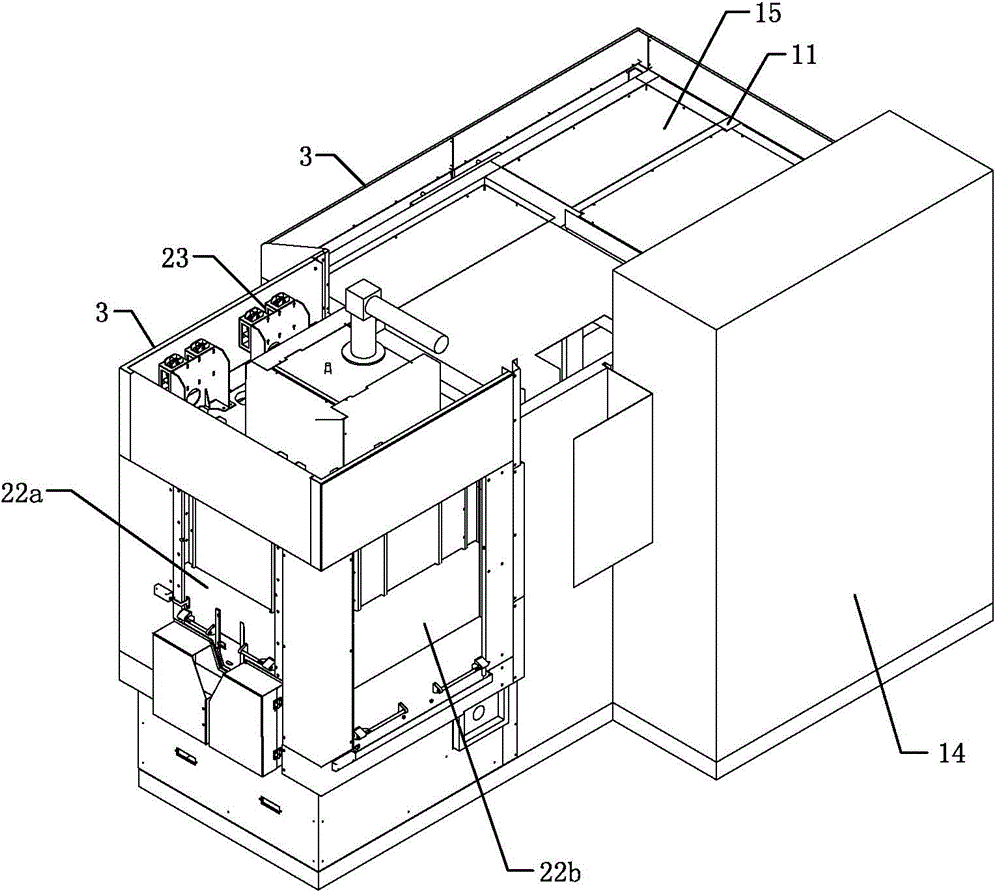

[0030] Such as figure 1 , figure 2 , image 3 with Figure 4 The external protective system for the silicon cutting machine tool shown includes the machine bed protective cover 1 and the machine tool processing area protective cover 2;

[0031] Machine tool bed protective cover 1 comprises: cover as the machine bed external frame 11 outside the machine bed, be fixed on the rear end protection mechanism 12 of bed external frame 11 rear ends, left side protection mechanism 13, right side protection mechanism 14 and be fixed on The top sealing plate 15 at the top of the outer frame 11 of the bed, wherein the structure of the top sealing plate 15 is selectively assembled according to the actu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com