Apparatus for manufacturing membrane electrode assembly

An equipment and electrode technology, applied in the field of equipment for manufacturing membrane electrode assemblies, can solve the problems of increased product inferiority and exclusion, and achieve the effects of reducing defective products, improving productivity, and solving the increase in manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

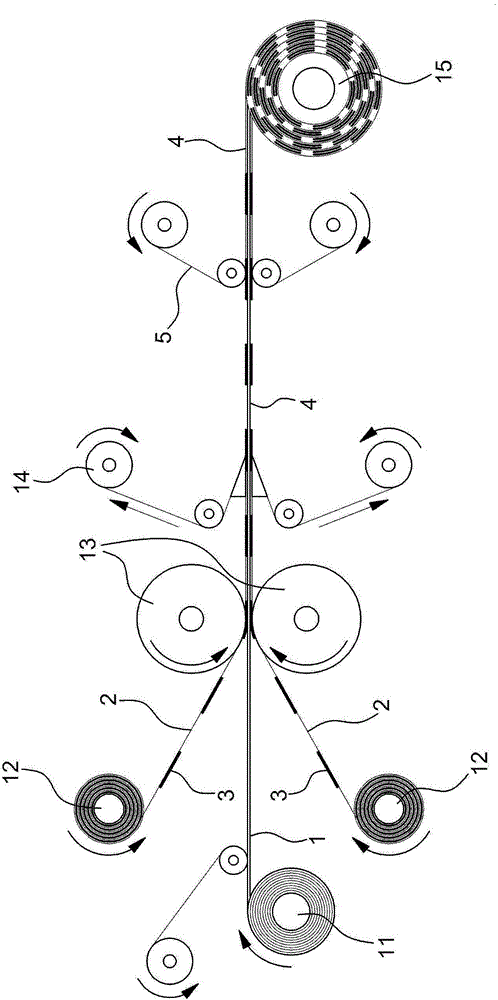

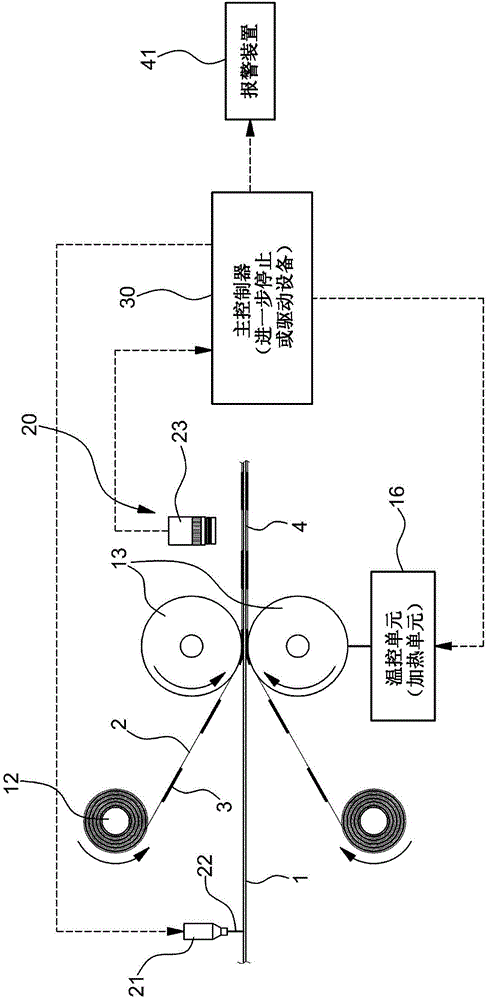

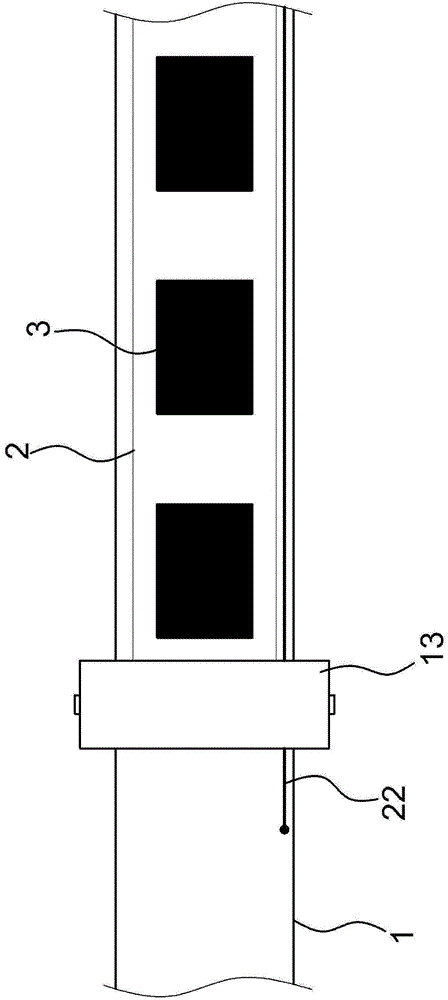

[0043] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0044] The invention provides a device for manufacturing a membrane electrode assembly by checking whether the temperature control of the transfer roller is abnormal, so as to select the driving mode / stop mode.

[0045] More specifically, the present invention provides an apparatus for manufacturing a membrane electrode assembly, including monitoring and checking whether there is a failure of temperature control, so that the temperature of the transfer roller exceeds the temperature limit in the manufacturing process, thereby automatically selecting the drive mode / stop mode, Or when the temperature of the transfer roller exceeds a predetermined temperature, that is, an appropriate temperature range, a system that continues the manufacturing process by taking necessary follow-up measures to prevent the MEA from being inferior.

[0046] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com