Production method for preparing dioctyl terephthalate by virtue of alcoholysis and esterification of polyester wastes

A technology of dioctyl terephthalate and its production method is applied in the field of alcoholysis and esterification of polyester waste to prepare dioctyl terephthalate, which can solve the problems of high price and high cost, and achieve high price, high production cost, The effect of complete response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

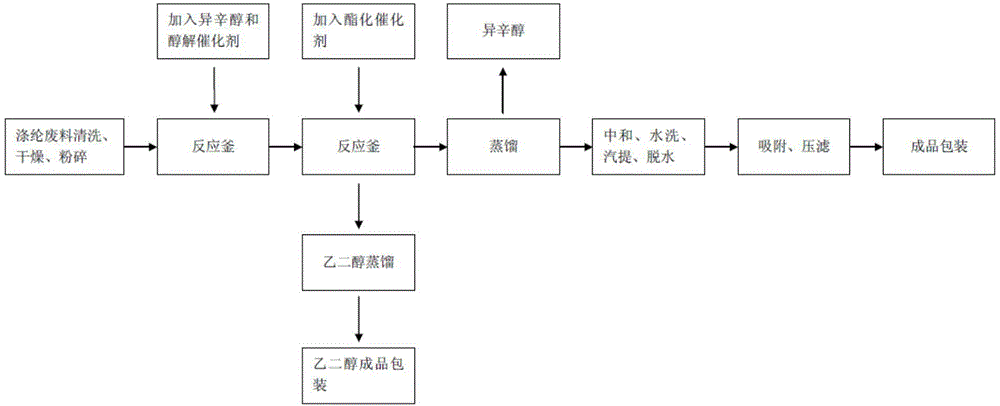

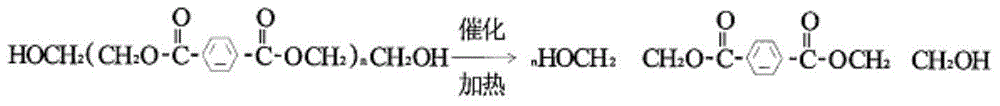

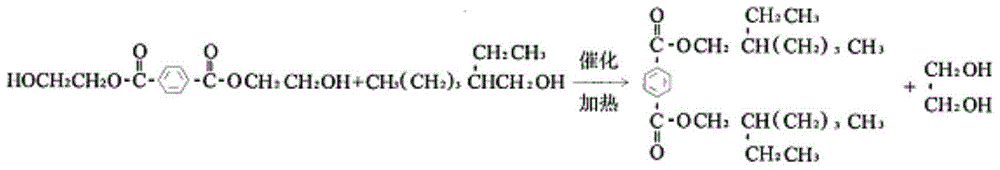

Method used

Image

Examples

Embodiment 1

[0024] A production method for preparing dioctyl terephthalate through alcoholysis and esterification of polyester waste, comprising the steps of:

[0025] (1) Rinse the polyester waste with water, put it into an oven at a temperature of 100-110° C. and dry it for 1 hour; pulverize the dried polyester waste into powder with a pulverizer;

[0026] (2) Accurately weigh 400g of polyester waste powder and 680g of isooctyl alcohol in step (1), add them to a 2000mL high-temperature and high-pressure reactor, add 1.08g of zinc acetate and zinc oxide composite catalyst, and heat up to 180°C for alcoholysis for 1 hour ;

[0027] (3) After the alcoholysis reaction is completed, the temperature is lowered to 135°C, 1.08g of tetraisopropyl titanate is added, and the temperature is raised to 220°C for esterification reaction for 20 hours;

[0028] (4) After the reaction is finished, use a vacuum pump to evacuate, and carry out vacuum distillation on the reaction product of step (3). The t...

Embodiment 2

[0031] (1) Rinse the polyester waste with water, put it into an oven at a temperature of 100-110° C. to dry for 1 hour, and grind the dried polyester waste into powder with a pulverizer;

[0032] (2) Accurately weigh 400g of polyester powder, put 720g of isooctyl alcohol into a 2000mL high-temperature and high-pressure reactor, add 1.12g of zinc acetate and zinc oxide composite catalyst, and heat up to 185°C for alcoholysis for 2 hours;

[0033] (3) The alcoholysis reaction is completed, the temperature is lowered to 145°C, 1.12g of tetraisopropyl titanate is added, the temperature is raised to 230°C, and the esterification reaction is carried out for 24 hours;

[0034] (4) After the reaction, use a vacuum pump to evacuate and carry out vacuum distillation. The temperature rises with 230°C as the cut-off point, and extracts separately: the isooctyl alcohol collected before 230°C is for later use; 230-270°C is extracted and collected What is crude dioctyl terephthalate; the eth...

Embodiment 3

[0037] (1) Rinse the polyester waste with water, put it into an oven at a temperature of 100-110° C. to dry for 1 hour, and grind the dried polyester waste into powder with a pulverizer;

[0038] (2) Accurately weigh 400g of polyester powder, put 700g of isooctyl alcohol into a 2000mL high-temperature and high-pressure reactor, add 1.1g of zinc acetate and zinc oxide composite catalyst, and heat up to 182°C for alcoholysis for 1.5h;

[0039] (3) After the alcoholysis reaction, the temperature was lowered to 140°C, 1.1g of tetraisopropyl titanate was added, the temperature was raised to 225°C, and the esterification reaction was carried out for 22 hours;

[0040] (4) After the reaction, use a vacuum pump to evacuate and carry out vacuum distillation. The temperature rises at 230°C as the cut-off point, and extracts respectively: the isooctyl alcohol collected before 230°C is for later use; 230-270°C for extraction What is collected is crude dioctyl terephthalate; the ethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com