A heat-resistant and stable polyethylene composition

A heat-resistant stability and composition technology, applied in the field of polyethylene resin composition, can solve the problems of insufficient long-term thermal aging performance, achieve good high-temperature oxidation resistance, high long-term heat-resistant stability, and improve thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

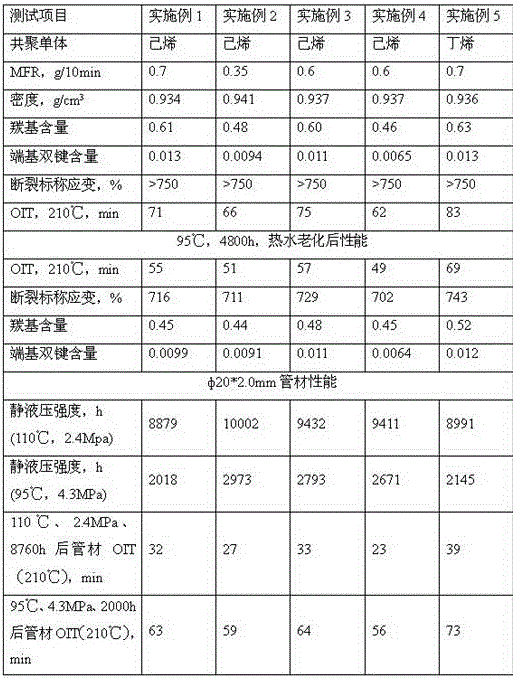

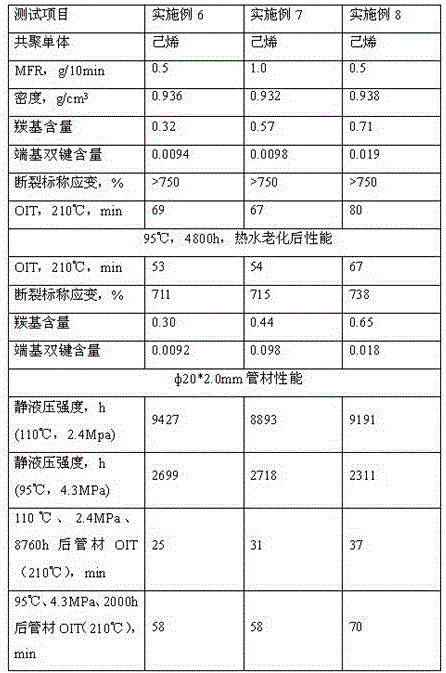

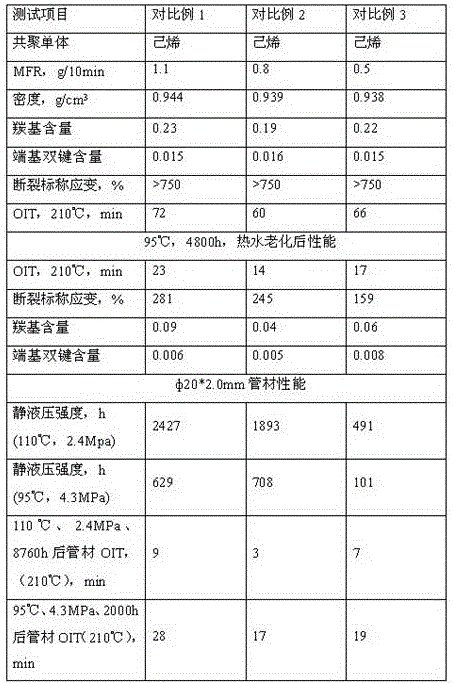

[0022] A heat-resistant and stable polyethylene composition of the present invention will be further described below through specific examples, wherein Example 1 is the best example.

[0023] The proportioning components of the polyethylene resin composition for hot water pipes are shown in Table 1 and Table 2.

[0024] Density is tested according to GB / T 1033.2-2010, using method D, and tested after boiling for 30 minutes; melt mass flow rate (MFR) is tested according to GB / T 3682-2000, with a load of 2.16kg; the amount of double bonds at the end of the composition And the test method of carbonyl content is: use a hot-pressed film machine to sample, the sample thickness is 250µm, the tablet temperature is 170°C, the pressure is 2MPa, the preheating is 30s, the pressure holding time is 0.5min, and the pressure is released and directly cooled to below 50°C; infrared spectrum collection The condition is to scan 32 times and the resolution is 4; -1 The area between the carbonyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com