High-purity iron pearlescent pigment and manufacturing method thereof

A pearlescent pigment and a production method technology, which are applied in the directions of inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., to achieve the effects of improving vividness, simple operation method and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

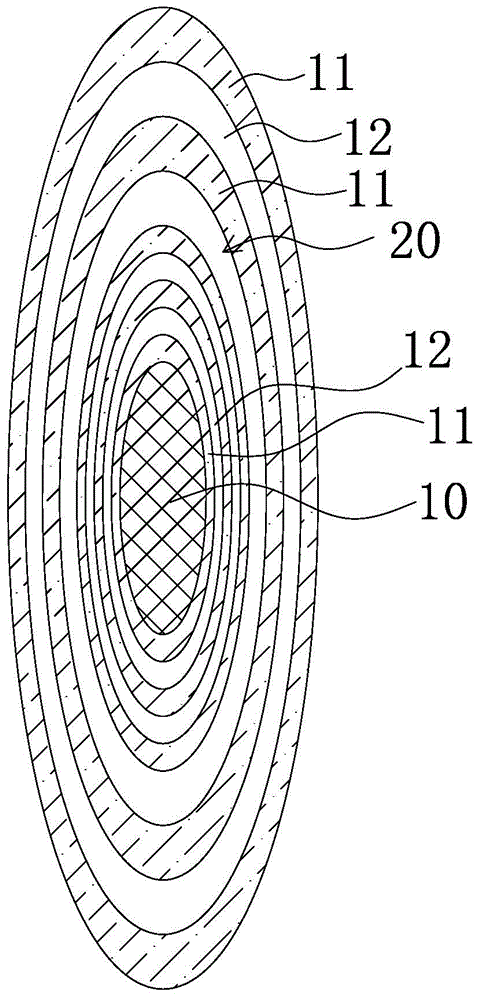

[0036] A high-purity iron pearlescent pigment, comprising a pearlescent pigment substrate 10, the outer surface of the pearlescent pigment substrate 10 is coated with Fe 2 o 3 cladding layer 11, the Fe 2 o 3 Between the cladding layer 11 and the pearlescent pigment substrate 10, several layers of composite layers 20 capable of reflecting and refracting light are coated, and the composite layers 20 are made of Fe 2 o 3 The cladding layer 11 and the auxiliary metal oxide layer 12 containing metal oxides of non-ferrous elements are composed, and the auxiliary metal oxide layer 12 is located between two layers of Fe 2 o 3 Between the cladding layers 11.

[0037] The aforementioned pearlescent pigment substrate 10 is one or more of natural mica, synthetic mica and glass. The metal oxide in the auxiliary metal oxide layer 12 is TiO 2 , ZrO 2 and one or more of ZnO.

[0038] Preferably, the composite layer 20 has four layers in total, and the metal oxide in the auxiliary met...

Embodiment 2

[0040] A preparation method of high-purity iron pearlescent pigment, comprising the following steps:

[0041] A. Feeding, add pearlescent pigment base material in the reaction vessel, add water, stir and heat up, add acid solution to adjust pH to acidic;

[0042] B. Add FeCl to the reaction vessel 3 solution, and add alkali solution to adjust the pH to be alkaline, and stir at constant temperature;

[0043] C. Add TiCl dropwise 4 or ZrCl 4 or ZnCl 2 solution into the reaction vessel, and stir;

[0044] D. Repeat steps B-C several times;

[0045] E. Add FeCl to the reaction vessel 3 solution, and adjust the pH to alkaline with alkali solution, and continue stirring at constant temperature;

[0046] F, washing the solid material in the reaction vessel with water, separating, drying and roasting to obtain high-purity iron pearlescent pigment.

[0047] Preferably, in step A, the temperature is raised to 80° C., and an acid solution is added to adjust the pH to 3; in step B, ...

Embodiment 3

[0051] Preparation of High Purity Bronze Pearlescent Pigment CR7500

[0052] 1. Put 30g of 10-60μm mica powder into a 1000ml beaker;

[0053] 2. Add water to 500ml, stir and heat up to 80°C;

[0054] 3. Control the speed at 350 rpm, and adjust the pH to 3.0;

[0055] 4. Begin to add 10ml of FeCl with a concentration of 1mol / L 3 solution, while maintaining a constant pH with 4mol / L NaOH solution, and stirring at constant temperature for 10 minutes after the addition;

[0056] 5. Drop 1ml of TiCl with a concentration of 2mol / L into the beaker 4 solution. Stir for 10 minutes after addition;

[0057] 6. Repeat steps 4 and 5 three times to complete 4 layers of TiO 2 the covering;

[0058] 7. Continue to drop about 270ml of FeCl with a concentration of 1mol / L 3 solution, while maintaining a constant pH with 4mol / L NaOH solution until the color reaches bronze, and continue to stir at constant temperature for 30 minutes;

[0059] 8. Wash and separate the materials in the beak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com