Mixed molten salt heat storage and heat transfer material and preparation method thereof

A technology of mixing molten salt and heat storage, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of narrow operating temperature range, inability to meet high demand, general thermal stability, etc., and achieve a wide operating temperature range. , the preparation process is simple and easy, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

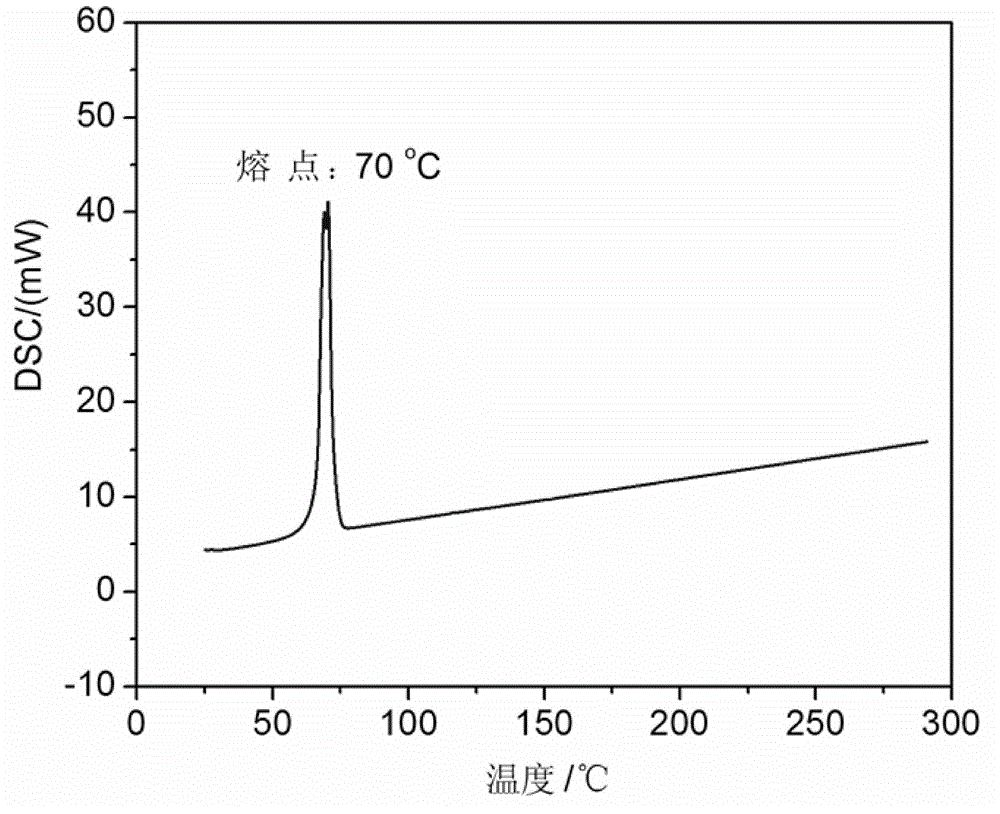

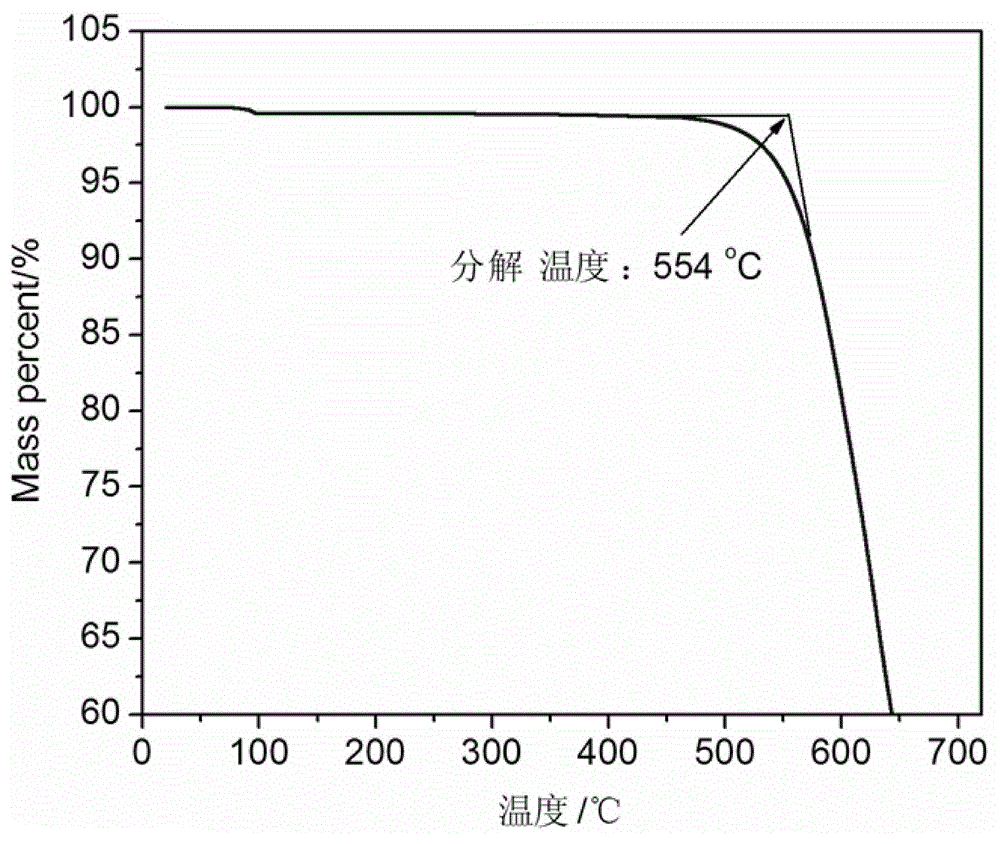

[0055] The mixed molten salt heat storage and heat transfer material provided in this embodiment is composed of 30wt% LiNO 3 , 1.5wt% NaNO 3 , 2.5wt% KNO 3 , 16wt%NaNO 2 , 50wt% KNO 2 After testing and analysis, it has a melting point of 70°C and a thermal decomposition temperature of 554°C. After testing, such as figure 1 Shown is the DSC curve of the sample; figure 2 Is the TG curve of the sample.

[0056] Compared with Solar Salt, the product's melting point has been reduced by nearly 150°C, and its use temperature range is 70-554°C, and a wider use temperature range has been obtained.

Embodiment 2

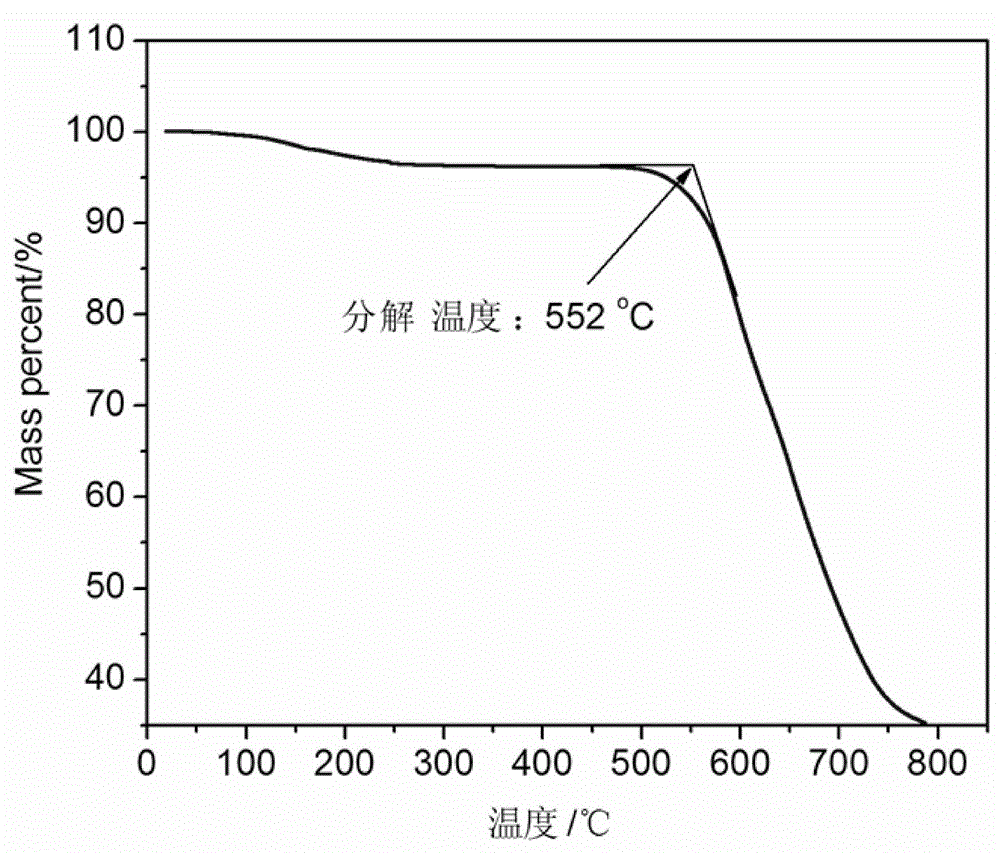

[0058] The mixed molten salt heat storage and heat transfer material provided in this embodiment is composed of 35wt% LiNO 3 , 4wt%NaNO 3 , 8wt% KNO 3 , 5wt%NaNO 2 , 48wt% KNO 2 After testing and analysis, it has a melting point of 69°C and a thermal decomposition temperature of 556°C.

Embodiment 3

[0060] The mixed molten salt heat storage and heat transfer material provided in this embodiment is composed of 28wt% LiNO 3 , 3wt%NaNO 3 , 4wt% KNO 3 , 10wt% NaNO 2 , 55wt% KNO 2 After testing and analysis, it has a melting point of 68°C and a thermal decomposition temperature of 560°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com