Hydraulic stirring anaerobic tank

A technology of hydraulic stirring and anaerobic tank, applied in the field of anaerobic tank, can solve the problems of inability to discharge supernatant, growth inhibition of anaerobic bacteria, no longer existence of supernatant, etc., so as to improve biogas production efficiency and anaerobic Oxygen efficiency, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Exemplary embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Here, it should be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same structure and function, and redundant descriptions on components that are substantially the same are omitted in order to make the description more concise.

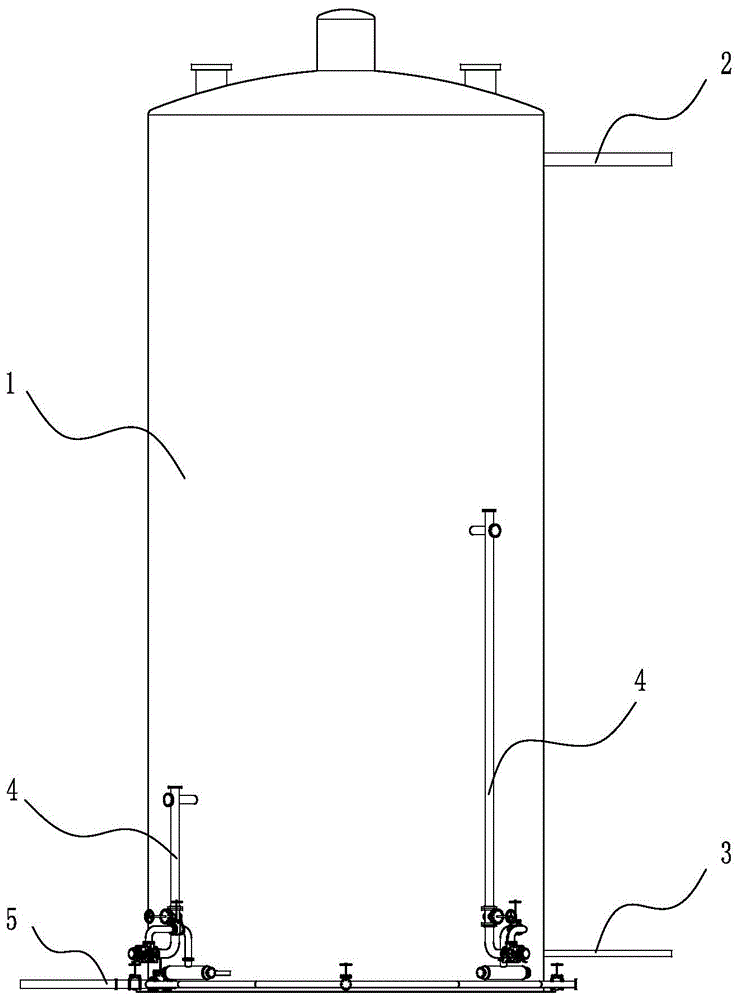

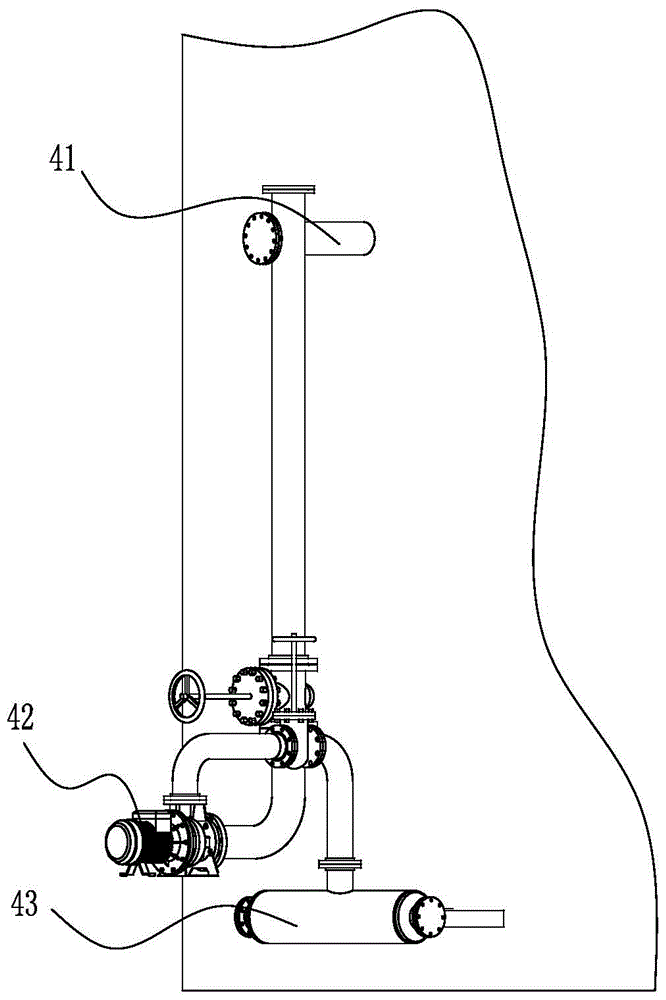

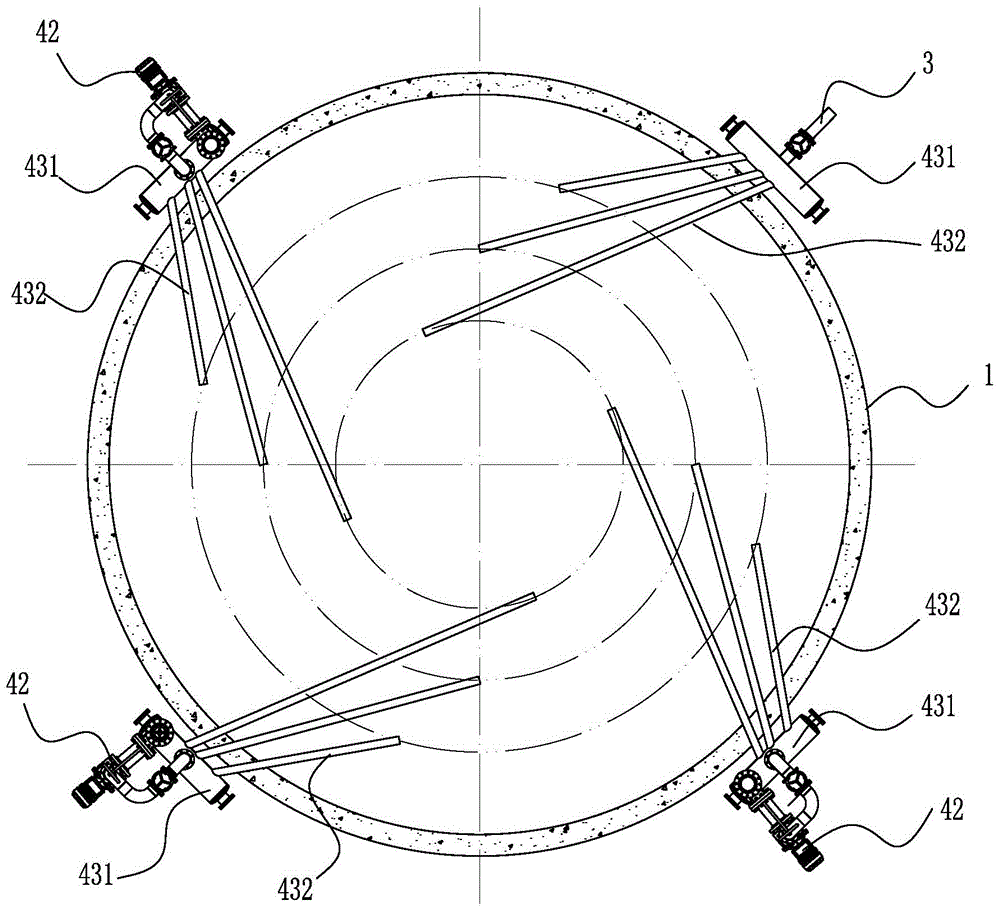

[0021] like figure 1 and figure 2 As shown, the hydraulic agitation anaerobic tank includes a tank body 1, the upper part of the tank body 1 is provided with a supernatant liquid outlet pipe 2, and the bottom part of the tank body 1 is provided with an anaerobic liquid inlet pipe 3, the The bottom of the tank body 1 is provided with a sludge discharge device 5, and at least two hydraulic agitation devices 4 are arranged on the outer peripheral wall of the tank body 1 above the sludge discharge device 5; the hydraulic agitation devices 4 include end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com