Method for producing conjugated linoleic acid by adsorbing and immobilizing permeabilized lactic acid bacteria to transform rapeseed oil waste

A conjugated linoleic acid, adsorption and immobilization technology, applied in microorganism-based methods, biochemical equipment and methods, immobilized on or in inorganic carriers, etc., can solve complex products, long growth cycle, difficult separation and extraction, etc. problems, to achieve the effect of high transformed cell density, less interfering substances, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

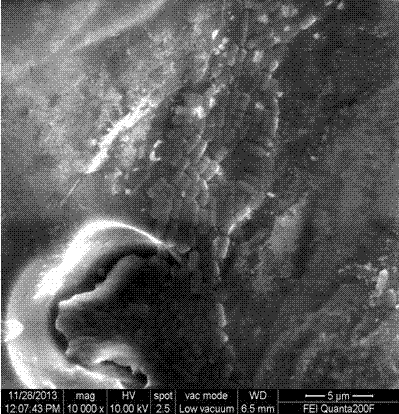

Image

Examples

Embodiment 1

[0016] (1) Pretreatment of the adsorption and immobilization carrier: Crush the waste ceramics to obtain porous ceramic particles with a diameter of 4-6 mm. Soak in NaOH solution for 24 h, and finally wash with water until neutral, dry, and sterilize to obtain a sterile adsorption immobilized porous ceramic carrier.

[0017] (2) Preparation of permeabilized lactic acid bacteria: Pick 3-ring Lactobacillus acidophilus CGMCC1.1854 from fresh slant culture medium, inoculate it into 150 mL MRS medium, and incubate anaerobically at 37°C for 20 hours to obtain a lactic acid bacteria suspension , Take the bacterial suspension and continue to expand the culture in the MRS medium. Centrifuge the bacterial suspension at 4°C and 5000 rpm for 20 min, remove the supernatant, freeze the bacterial cells at -20°C, take them out, thaw them at room temperature, and repeat freezing and thawing twice to obtain permeabilized lactic acid bacteria.

[0018] (3) Adsorption and immobilization of perme...

Embodiment 2

[0022] (1) Pretreatment of adsorption and immobilization carrier: Crush waste ceramics to obtain porous ceramic particles with a diameter of 4-6 mm. Soak in NaOH solution for 24 h, and finally wash with water until neutral, dry, and sterilize to obtain a sterile adsorption immobilized porous ceramic carrier.

[0023] (2) Preparation of permeabilized lactic acid bacteria: Pick 2-ring Lactobacillus acidophilus CGMCC1.1854 from the fresh slant medium, inoculate it into 100 mL MRS medium, and culture it anaerobically at 35°C for 24 hours to obtain a lactic acid bacteria suspension , Take the bacterial suspension and continue to expand the culture in the MRS medium. Centrifuge the bacterial suspension at 4°C and 5000 rpm for 20 min, remove the supernatant, freeze the bacterial cells at -20°C, take them out, thaw them at room temperature, and repeat freezing and thawing 3 times to obtain permeabilized lactic acid bacteria.

[0024] (3) Adsorption and immobilization of permeabilized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com