Anti-vibration type rapid splicing platform

A fast and platform technology, applied in the platform field, can solve the problems of slow assembly and disassembly, inconvenient cleaning, easy damage, etc., and achieve the effect of beautiful area, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

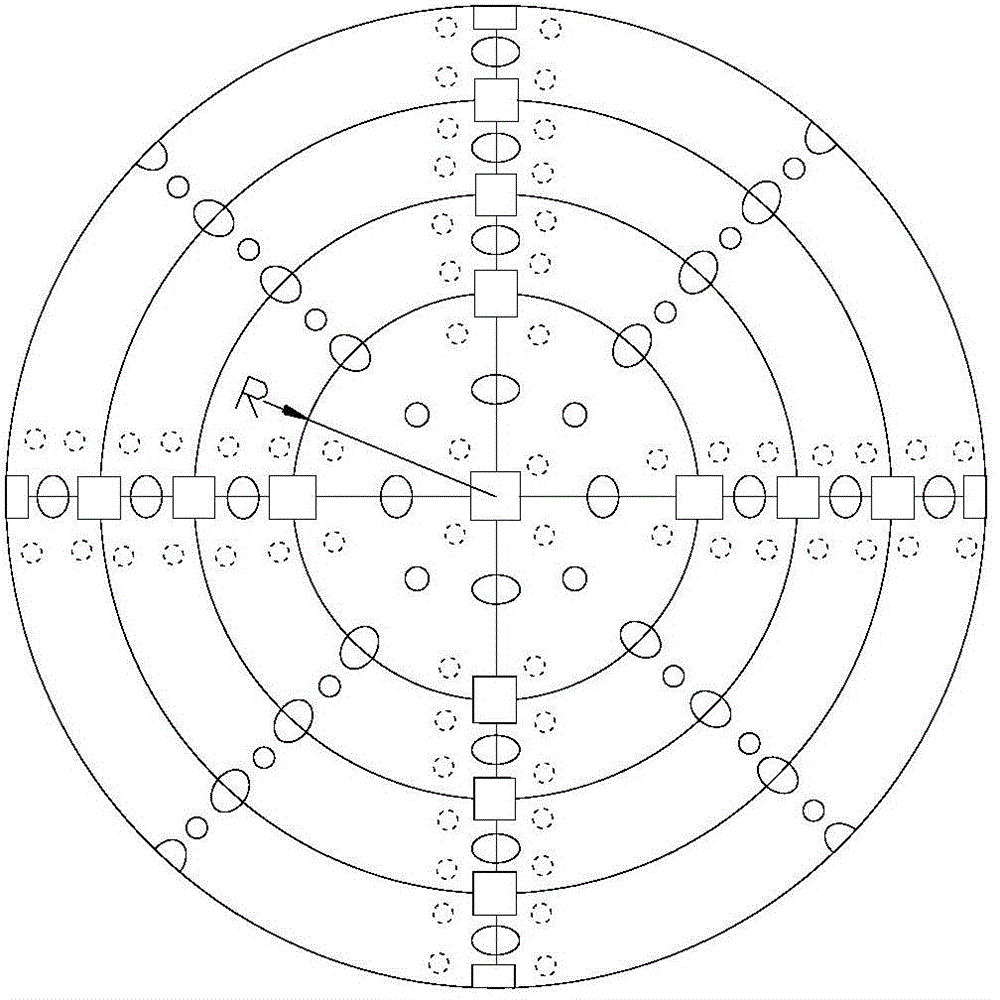

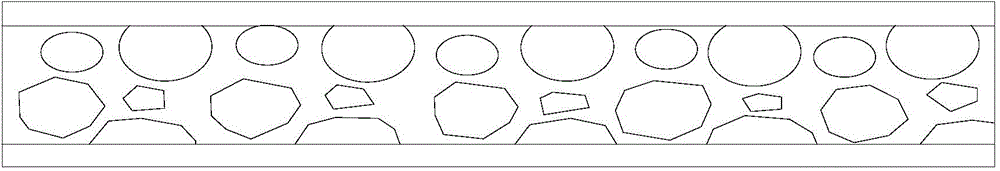

[0030] Such as figure 1 with figure 2 As shown, the anti-vibration quick assembly platform of the present invention comprises four identical fan-shaped splicing plates and multiple annular splicing plates;

[0031] The central angle of the fan-shaped splicing plate is 90 degrees, and the radius is denoted as R; the corresponding central angle of the circular splicing plate is 90 degrees;

[0032] The annular splicing plates are divided into the first type of annular splicing plates, the second type of annular splicing plates, the third type of annular splicing plates...the nth type of annular splicing plates;

[0033] The thickness of the annular splicing plates is the same, denoted as H, the inner diameter of the first type of annular splicing plate is the same as the sector radius is R, the inner diameter of the second type of annular splicing plate is R+H, and the inner diameter of the third type of annular splicing plate is R+2H ...The inner diameter of the nth type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com