Preparation method for extruded polystyrene (XPS)-foaming cement composite self-thermal-insulation vertical wall building block

A technology of foaming cement and foaming water, which is applied in the direction of manufacturing tools, ceramic products, applications, etc., to achieve the effects of easy processing and production, low cost and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of XPS insulation board template:

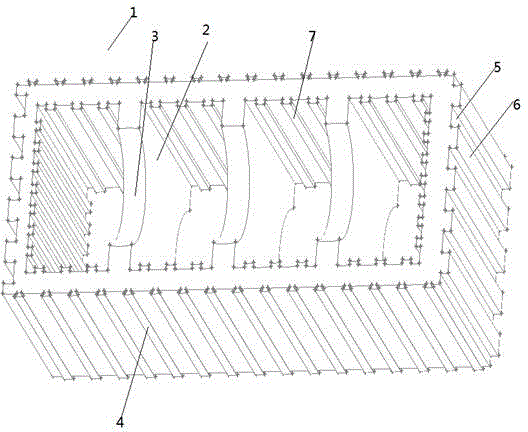

[0031] The straight-wall block type XPS insulation board formwork was prepared by extrusion molding process; the structure of the XPS insulation board formwork is as follows figure 1 As shown, the XPS insulation board mold body is a cuboid structure 1 with a cavity in the middle, length × height × thickness = 60cm × 36cm × 24cm, the wall thickness of the XPS insulation board mold body is 5cm, and a connection is arranged in the cavity Reinforcing rib 2; the thickness of the connecting reinforcing rib is 5cm, and the interval between connecting reinforcing ribs is 10cm.

[0032] An arc-shaped groove 3 with a radius of 10 cm is provided in the middle of the top surface and bottom surface of the reinforcing rib, and the height from the bottom end to the top end of the groove is 10 cm.

[0033] Dovetail grooves 4 are provided on the front and rear surfaces of the XPS insulation board template. The width of the dovetail gro...

Embodiment 2

[0080] 1) Preparation of XPS insulation board template:

[0081] The straight-wall block type XPS insulation board formwork was prepared by extrusion molding process; the structure of the XPS insulation board formwork is as follows figure 1 As shown, the XPS insulation board mold body is a cuboid structure 1 with a cavity in the middle, length × height × thickness = 60cm × 36cm × 24cm, the wall thickness of the XPS insulation board mold body is 5cm, and a connection is arranged in the cavity Reinforcing rib 2; the thickness of the connecting reinforcing rib is 5cm, and the interval between connecting reinforcing ribs is 10cm.

[0082] An arc-shaped groove 3 with a radius of 4 cm is provided in the middle of the top and bottom of the reinforcing rib, and the height from the bottom to the top of the groove is 4 cm.

[0083] Dovetail grooves 4 are provided on the front and rear surfaces of the XPS insulation board template. The width of the dovetail grooves is 2 cm, the depth is...

Embodiment 3

[0091] 1) Preparation of XPS insulation board template:

[0092] The straight-wall block type XPS insulation board formwork was prepared by extrusion molding process; the structure of the XPS insulation board formwork is as follows figure 1 As shown, the XPS insulation board mold body is a cuboid structure 1 with a cavity in the middle, length × height × thickness = 60cm × 36cm × 24cm, the wall thickness of the XPS insulation board mold body is 5cm, and a connection is arranged in the cavity Reinforcing rib 2; the thickness of the connecting reinforcing rib is 5cm, and the interval between connecting reinforcing ribs is 10cm.

[0093] An arc-shaped groove 3 with a radius of 30 cm is provided in the middle of the top surface and bottom surface of the reinforcing rib, and the height from the bottom end to the top end of the groove is 30 cm.

[0094] Dovetail grooves 4 are provided on the front and rear surfaces of the XPS insulation board template. The width of the dovetail groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com