Single-arm onboard roof bolter for underground coal mine

A technology of bolting machine and single arm, which is used in the installation of bolts, drilling equipment, mining equipment, etc., can solve the problem of inconvenient manual handling of roof and old bolts, lack of full-section bolt installation in roadways, and the range of swing angles. small problems, to achieve the effect of improving efficiency and safety, reducing labor intensity of workers, and widening the scope of bolt construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

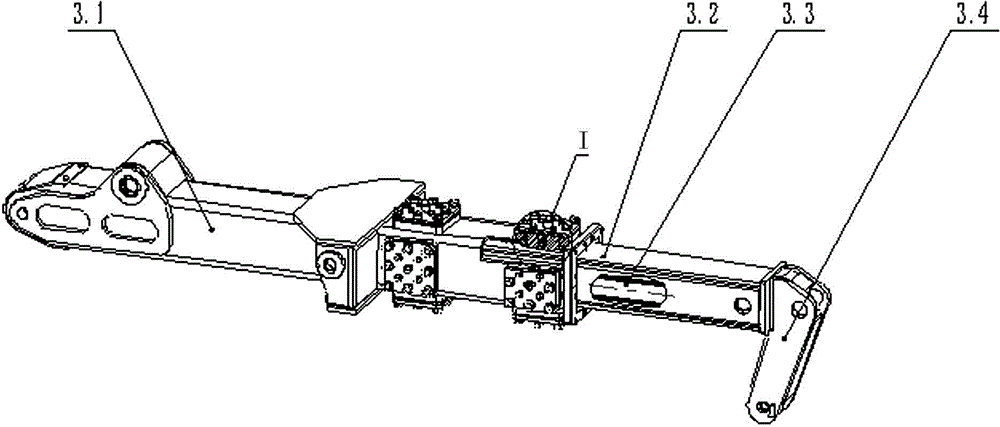

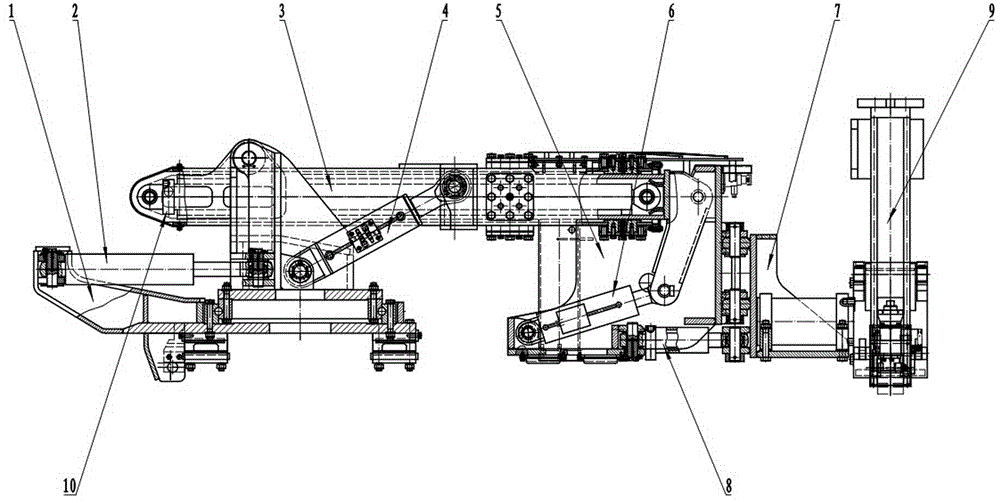

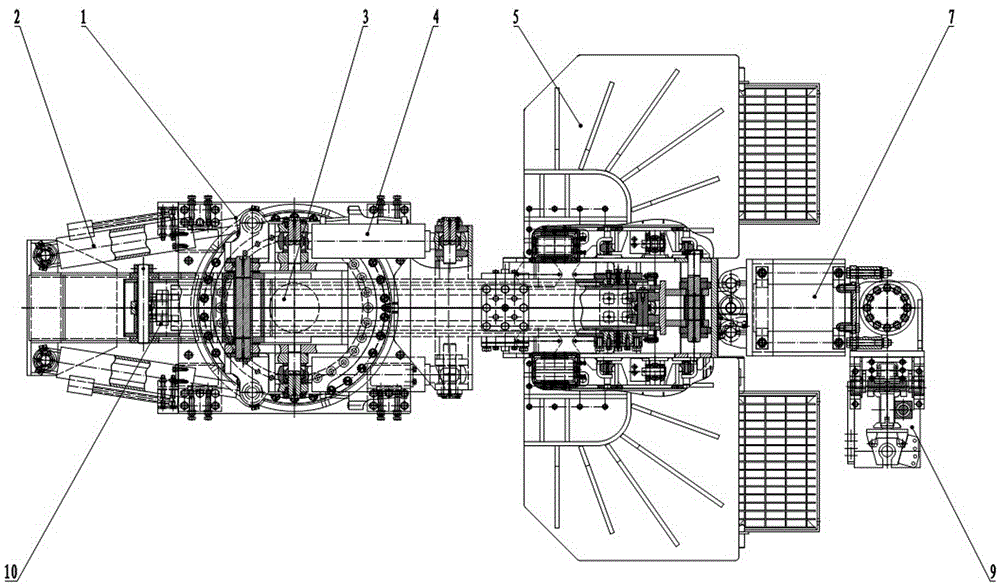

[0033] The single-arm airborne bolter for underground coal mines consists of a slewing base, a cantilever, an operating table assembly, a drill arm slewing device, and a drill stand. The slewing base 1 is composed of a base, a slewing bearing, a slewing seat, etc., and can slide and rotate. The cantilever 3 is connected with the rotary base 1 and the console assembly 5, and can realize telescopic function. The drilling boom rotating device 7 is installed on the front end of the console assembly 5, and is used for installing the drilling frame 9, and realizes the vertical and horizontal rotation of the drilling frame 9. figure 1 , 2 Shown is a structural diagram of the present invention, and the installation relationship shown in the figure should be correct, and the installation should be firm and reliable.

[0034] The whole set of equipment is installed on the fixed tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com