Double-blade swing hydraulic motor for driving stabilizing rod

A technology of swinging hydraulic motor and active stabilizer bar, which is applied in the directions of engine seals, engine components, fluid pressure actuating devices, etc., can solve the problems that the motor cannot use active stabilizer bars, low bearing capacity, large volume and weight, etc. High pressure leakage problem, overall weight reduction, low effect of manufacturing itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

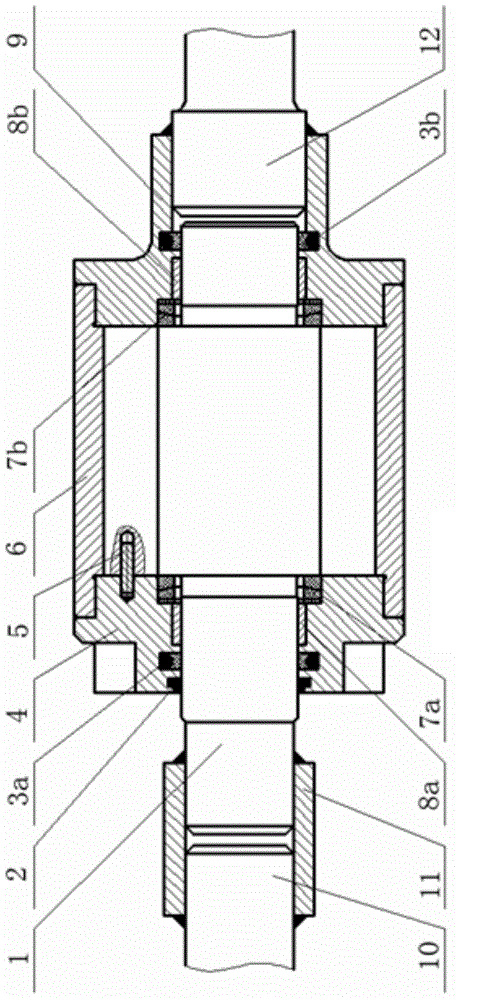

[0039] In this example, see figure 1 , a double-blade swing hydraulic motor for active stabilizer bars, including: an output shaft 1, a cylinder body 6, a front end cover 4 and a rear end cover 9; the output shaft 1 is supported and fixed on the cylinder by the front end cover 4 and the rear end cover 9 In the body 6; the active stabilizer bar includes the left half rod 10 of the stabilizer bar and the right half rod 12 of the stabilizer bar; the output shaft 1 on one side of the front cover 4 is welded to the left half rod 10 of the stabilizer bar through the sleeve 11; the rear end cover 9 is connected to the stabilizer bar The right half-rod 12 of the rod is welded, so that the double-blade swing hydraulic motor can use the output shaft 1 and the rear end cover 9 to drive the left half-rod 10 of the stabilizer bar and the right half-rod 12 of the stabilizer bar to move relatively;

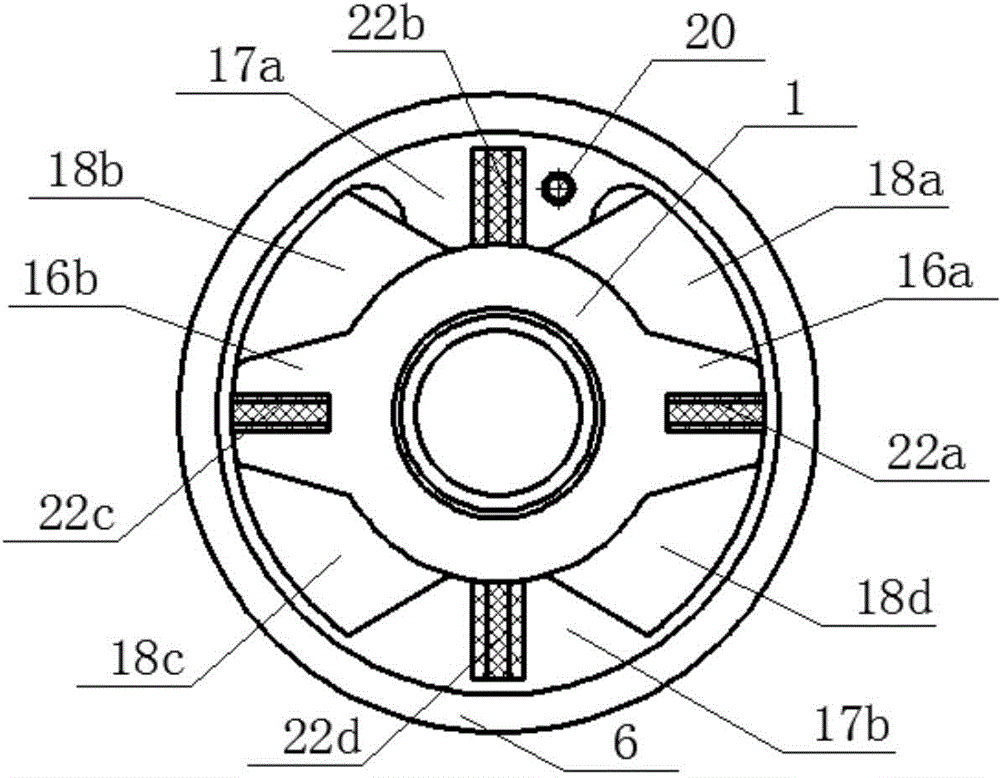

[0040] see Figure 6 , the stator blades are arranged symmetrically in the cylinder body 6;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com