Isolation guides for shock absorption

A technology for isolating guides and guide sleeves, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problem of reducing comfort and safety, affecting the shock absorption effect of shock absorbers, and uneven spring force changes and other problems, to achieve the effect of reducing the frictional contact area, good shock absorption accuracy, and saving materials and finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

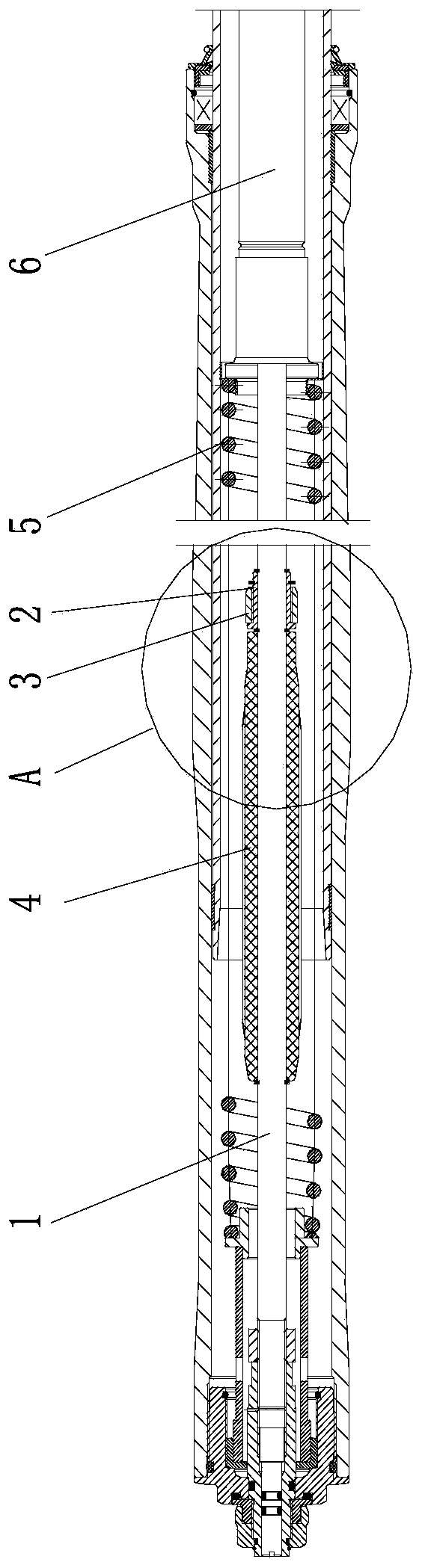

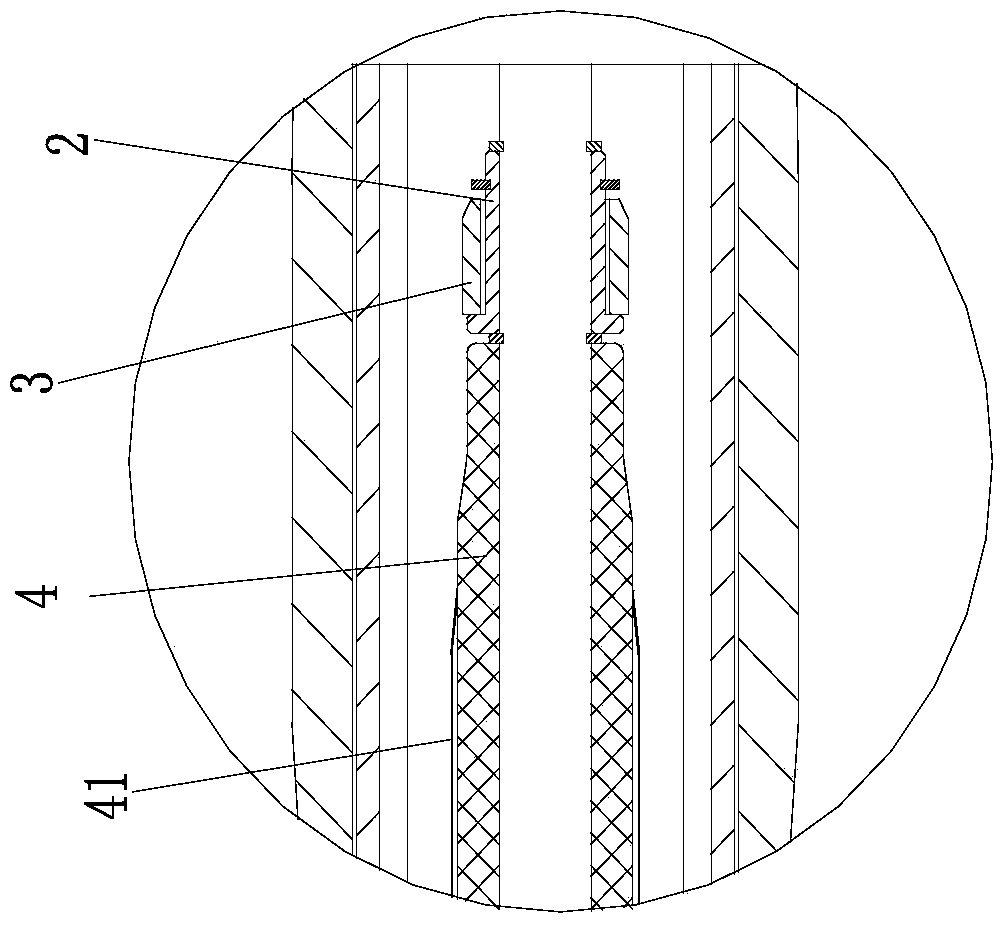

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view at place A, as shown in the figure: the isolation guide device for shock absorption of the present embodiment includes a guide sleeve 4 that is used to be placed in the middle of the piston rod 1 of the shock absorber; the guide sleeve 4 generally adopts a material softer than the spring 5 Materials, such as plastic or nylon, can prevent the spring 5 from bending and rubbing against the piston rod 1 to affect its performance or cause wear and tear on the piston rod and the spring during the working process of the spring 5, so that the whole working process is smoother.

[0020] In this embodiment, it also includes a hydraulic buffer 3 for at least axially outwardly limiting the piston rod 1. The position of the hydraulic buffer 3 prevents the piston of the piston assembly from rigidly touching the bottom at the end of the stroke; the axial direction Outward ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com