Spigot-and-socket connection type liner steel-plastic composite pipe and production method thereof

A technology of steel-plastic composite pipe and plastic steel, which is applied in the direction of sleeve/socket connection, non-detachable pipe connection, pipe/pipe joint/pipe fitting, etc., which can solve the problems of inconvenient maintenance, unreliable sealing, and low service life. Achieve the effect of convenient maintenance and disassembly, high sealing reliability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

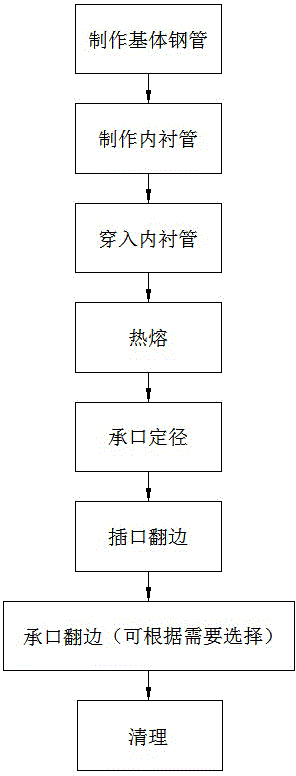

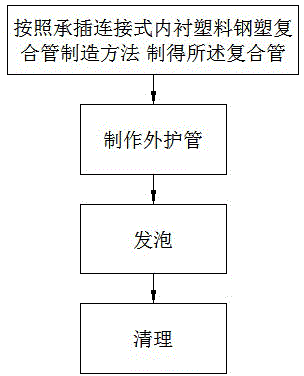

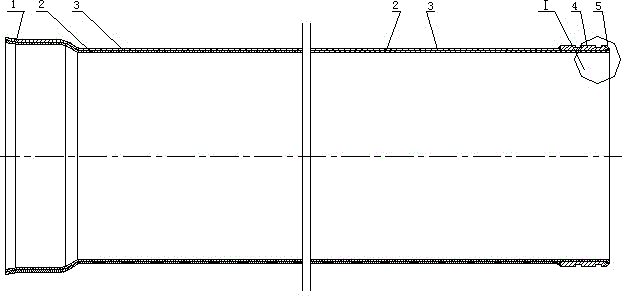

[0080] Embodiment 1, with reference to figure 1 , Figure 3 ~ Figure 5 , embodiment 1 is a kind of φ500×12000 socket-connected polyethylene-lined steel-plastic composite pipe, which includes equal-diameter steel pipe 3, socket steel pipe 4, trumpet-shaped socket 1 and polyethylene liner pipe 2, the The equal-diameter steel pipe 3 is a spiral welded steel pipe. One end of the equal-diameter steel pipe 3 is welded and fixed to the socket steel pipe 4, and the other end is welded and fixed to the small end of the horn-shaped socket 1. The polyethylene liner pipe 2 is fixedly connected to the socket steel pipe. 4 and the equal-diameter steel pipe 3 of the trumpet-shaped socket 1 are compounded and fixedly connected, and a socket tapered flange 5 is formed on the edge of the socket steel pipe 4 . The connecting structure between the adjacent front steel-plastic composite pipe 6 and the rear steel-plastic composite pipe 9 is: the spigot steel pipe 4 of the front steel-plastic compo...

Embodiment 2

[0126] Embodiment 2, with reference to figure 1 , Figure 3 ~ Figure 5 , Embodiment 2 is a φ500×12000 socket-connected polyethylene-lined steel-plastic composite pipe, the embodiment 2 is basically the same as the embodiment 1, the difference is that both the socket and the trumpet-shaped socket are carried out at the mouth Flanging, the manufacturing method is as follows:

[0127] 1) Making the base steel pipe

[0128] a. Load the strip material into the material chamber, run to the material cutting place, press and cut, two sheets are butted, pressed, and welded with gas shielded welding. The gas composition of gas shielded welding is 25% argon, 75% carbon dioxide, The flow rate is 0.5~0.6m3 / h, and the running speed of the material is 1.2m / min; DC-150 electric welding machine is used for welding, so that the welding wire is close to the workpiece, the flux buries the welding wire 50, and the welding starts, and the spiral welding in the tube hole is first carried out , an...

Embodiment 3

[0169] Embodiment 3, with reference to figure 1 , Figure 3 ~ Figure 5 , Example 3 is a φ500×12000 socket-connected polyethylene-lined steel-plastic composite pipe, which is basically the same as Example 2, except that some process parameters are different, and the manufacturing method is as follows:

[0170] 1) Making the base steel pipe

[0171] a. Load the strip material into the material chamber, run to the material cutting place, press and cut, two sheets are butted, pressed, and welded with gas shielded welding. The gas composition of gas shielded welding is 25% argon, 75% carbon dioxide, The flow rate is 0.5~0.6m3 / h, and the running speed of the material is 1.2m / min; DC-150 electric welding machine is used for welding, so that the welding wire is close to the workpiece, the flux buries the welding wire 50, and the welding starts, and the spiral welding in the tube hole is first carried out , and then perform spiral welding on the outer wall of the tube, the flux is si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com