A low energy consumption PTA oxidation tail gas catalytic combustion treatment method

A technology of catalytic combustion and oxidation of tail gas, applied in the combustion method, combustion type, incinerator, etc., can solve the problems of high material requirements of the expander, large loss of recovered energy, large airflow wave resistance, etc. Large, the effect of easing operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

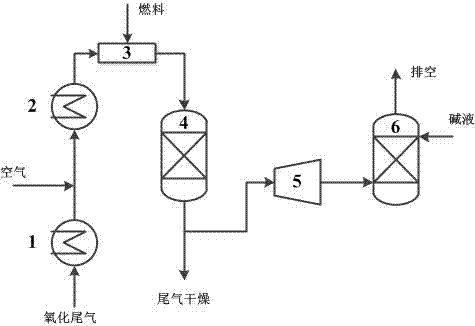

Image

Examples

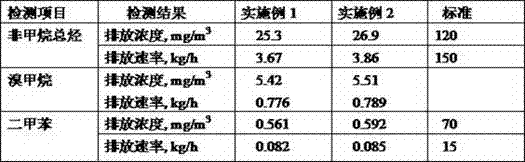

Embodiment 1

[0025] The production capacity of a certain PTA plant is 600 kt / a, and the operating conditions of the PX oxidation reactor are reaction temperature 194-200 °C, pressure 1.4-1.6 MPa; the oxidation tail gas is washed by a high-pressure absorption tower, p-xylene and methyl acetate are recovered, and the gas After liquid separation, the tail gas enters the High Pressure Catalytic Combustion System (HPCCU). The oxidation tail gas composition (wt %) before catalytic combustion treatment is as follows:

[0026] N 2 (92.85%), O 2 (3.98%), CO 2 (2.16%), H 2 O(0.37%),CO(0.51%),CH 3 Br (0.0077 %), other organic matter (0.1 %); oxidation tail gas flow rate 2639 kg / tPTA.

[0027] The specific steps of the improved catalytic combustion process are as follows:

[0028] (1) The oxidized tail gas from the high-pressure absorption tower enters the catalytic combustion preheater, the first preheater uses low-pressure steam to heat it to 130°C, and the second preheater uses high-pressure ...

Embodiment 2

[0040] The production capacity of a certain PTA plant is 600 kt / a, and the operating conditions of the PX oxidation reactor are reaction temperature 194-200 °C, pressure 1.4-1.6 MPa; the oxidation tail gas is washed by a high-pressure absorption tower, p-xylene and methyl acetate are recovered, and the gas After liquid separation, the tail gas enters the High Pressure Catalytic Combustion System (HPCCU). The oxidation tail gas composition (wt %) before catalytic combustion treatment is as follows:

[0041] N 2 (92.9%), O 2 (3.96%), CO 2 (2.15%), H 2 O(0.37%),CO(0.51%),CH 3 Br (0.0078 %), the remaining organic matter (0.1 %); the flow rate of oxidation tail gas is 2598 kg / tPTA.

[0042] The specific steps of the improved catalytic combustion process are as follows:

[0043] (1) The oxidized tail gas from the high-pressure absorption tower enters the catalytic combustion preheater, the first preheater uses low-pressure steam to heat it to 130°C, and the second preheater us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com