Flue gas treatment equipment of range hood

A technology for range hood and flue gas treatment, which is applied in the field of range hoods, and can solve problems such as insufficient filtration of filter screens and circular tubes, failure to consider the recycling of flue gas heat, and oily gas pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

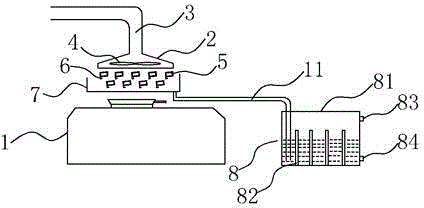

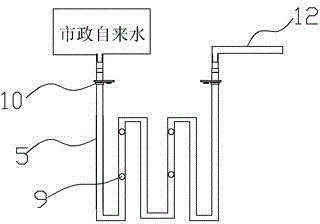

[0015] Such as figure 1 , figure 2 As shown, a flue gas treatment device for a range hood includes a range hood casing 2 arranged above a cooker 1 , a suction channel 3 is arranged inside the range hood casing 2 , and the end of the suction channel 3 A fan 4 is arranged above the stove, and an oil baffle is arranged below the fan 4. The oil baffle is composed of multiple stacked square oil baffles 5, and each layer of square oil baffles 5 is connected from end to end and is circuitous. , the installation positions of the adjacent square oil retaining pipes 5 of each layer are staggered, and the pipe body of the upper square oil retaining pipe is located above the pipe body gap of the adjacent lower floor square oil retaining pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com