An in-situ detection method for the phase transition process of crystalline polymers

A crystalline polymer and in-situ detection technology, which is applied in the detection field, can solve the problems of complex structure of detection devices, cumbersome operation methods, and difficulty in realization, and achieve the effects of fast detection steps, accurate detection results, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

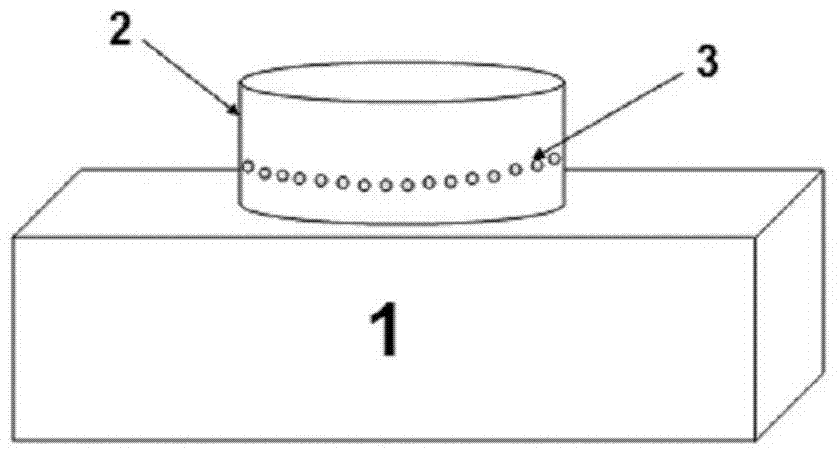

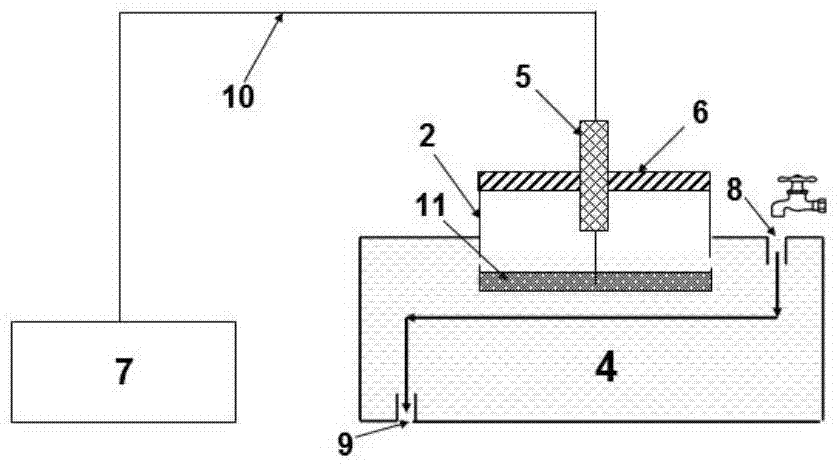

[0030] Schematic diagram of the structure of the in-situ detection device for the phase transition process of the crystalline polymer described in the present invention is as follows figure 1 , figure 2 shown.

[0031] The device includes two parts, namely a heating device and an in-situ testing device. The heating device includes a programmed temperature control heating table 1 and a specially designed metal container 2, the metal container 2 is a cylindrical stainless steel container with a radius of 20 mm and a height of 10 mm, and the metal container 2 is 4 mm away from the bottom. Thirty circular holes 3 with a radius of 0.75 mm are opened on the wall to allow cooling water to enter the metal container 2 to cool the polymer melt 11 . The in-situ test device includes the metal container 2 , a water tank 4 , a T-type thermocouple 5 , a fixing device (fixture) 6 and a temperature digital display 7 . A water inlet 8 is provided on the upper right of the water tank 4, and ...

Embodiment 2

[0042] Schematic diagram of the structure of the in-situ detection device for the phase transition process of the crystalline polymer described in the present invention is as follows figure 1 , figure 2 shown.

[0043] The device includes two parts, namely a heating device and an in-situ testing device. The heating device includes a programmed temperature control heating table 1 and a specially designed metal container 2, the metal container 2 is a cylindrical stainless steel container with a radius of 20 mm and a height of 10 mm, and the metal container 2 is 4 mm away from the bottom. Thirty circular holes 3 with a radius of 0.5 mm are opened on the wall to allow cooling water to enter the metal container 2 to cool the polymer melt 11 . The in-situ test device includes the metal container 2 , a water tank 4 , a T-type thermocouple 5 , a fixing device (fixture) 6 and a temperature digital display 7 . A water inlet 8 is provided on the upper right of the water tank 4, and a...

Embodiment 3

[0054] Schematic diagram of the structure of the in-situ detection device for the phase transition process of the crystalline polymer described in the present invention is as follows figure 1 , figure 2 shown.

[0055] The device includes two parts, namely a heating device and an in-situ testing device. The heating device includes a programmed temperature control heating table 1 and a specially designed metal container 2, the metal container 2 is a cylindrical stainless steel container with a radius of 20 mm and a height of 10 mm, and the metal container 2 is 4 mm away from the bottom. Thirty circular holes 3 with a radius of 1.0mm are opened on the wall to allow cooling water to enter the metal container 2 to cool the polymer melt 11 . The in-situ test device includes the metal container 2 , a water tank 4 , a T-type thermocouple 5 , a fixing device (fixture) 6 and a temperature digital display 7 . A water inlet 8 is provided on the upper right of the water tank 4, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com