Intelligent numerical-control engraving machine controller

An intelligent controller and machine tool technology, applied in the field of 3D printing, can solve the problems of occupying a large installation space, poor flexibility, and the inability of computers to perform other operations, and achieve the effect of wide application range, low cost, and rich functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

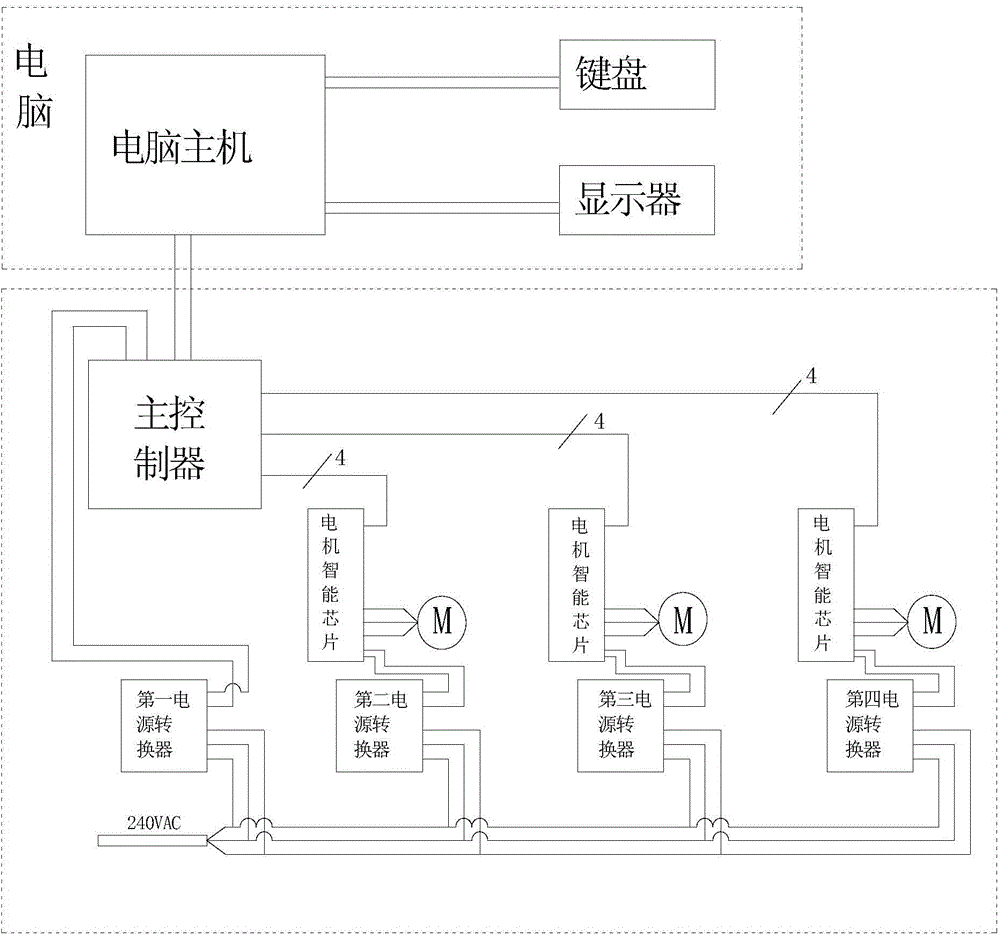

Embodiment 1

[0038] Embodiment one: if image 3 , Figure 4A , Figure 4B with Figure 5 As shown, this embodiment is an intelligent controller for a CNC engraving machine tool, including a power supply part located on a circuit board, a main control microprocessor, and several motor drive modules. The power supply part supplies power to various circuits, and the main control microprocessor The output end of the controller is connected to the motor drive module, several motor drive modules are provided with output ports directly connected to the motor, the main control microprocessor is connected with a data transmission interface module and a display, and the NC code file is sent to the main control through the data transmission interface module Microprocessor, the main control microprocessor is equipped with an instruction execution module, which can read the NC code file input from the outside, and read, analyze, calculate, judge, and convert each instruction and parameter in the NC cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com