Laminated type X-ray filter grating, and manufacturing device and manufacturing method thereof

A manufacturing device and a layered technology, applied in the field of X-ray filter grids, can solve the problems of complex procedures, high price of X-ray filter grids, time-consuming and other problems, and achieve the effect of high absorption efficiency, clear images or image signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0152] Embodiments of the laminated X-ray grating, its manufacturing apparatus, and manufacturing method according to the present invention will be described in detail below with reference to the drawings.

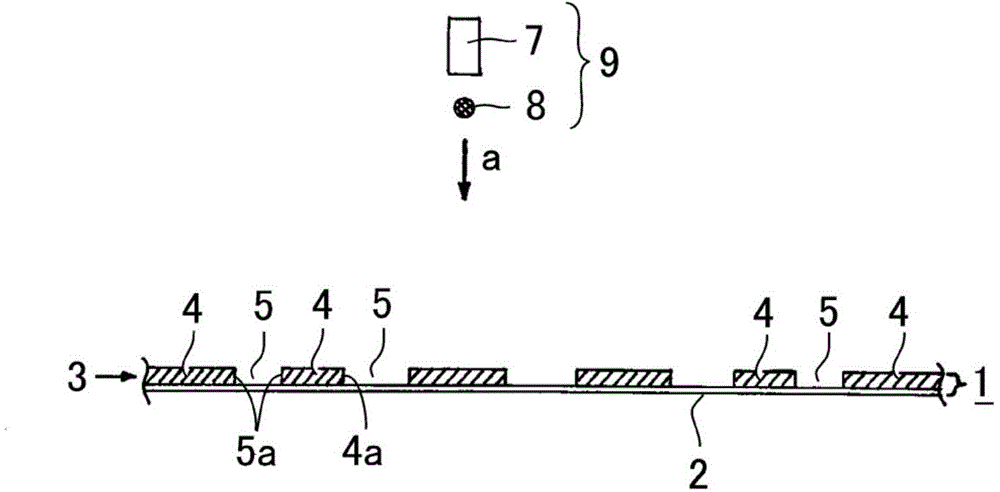

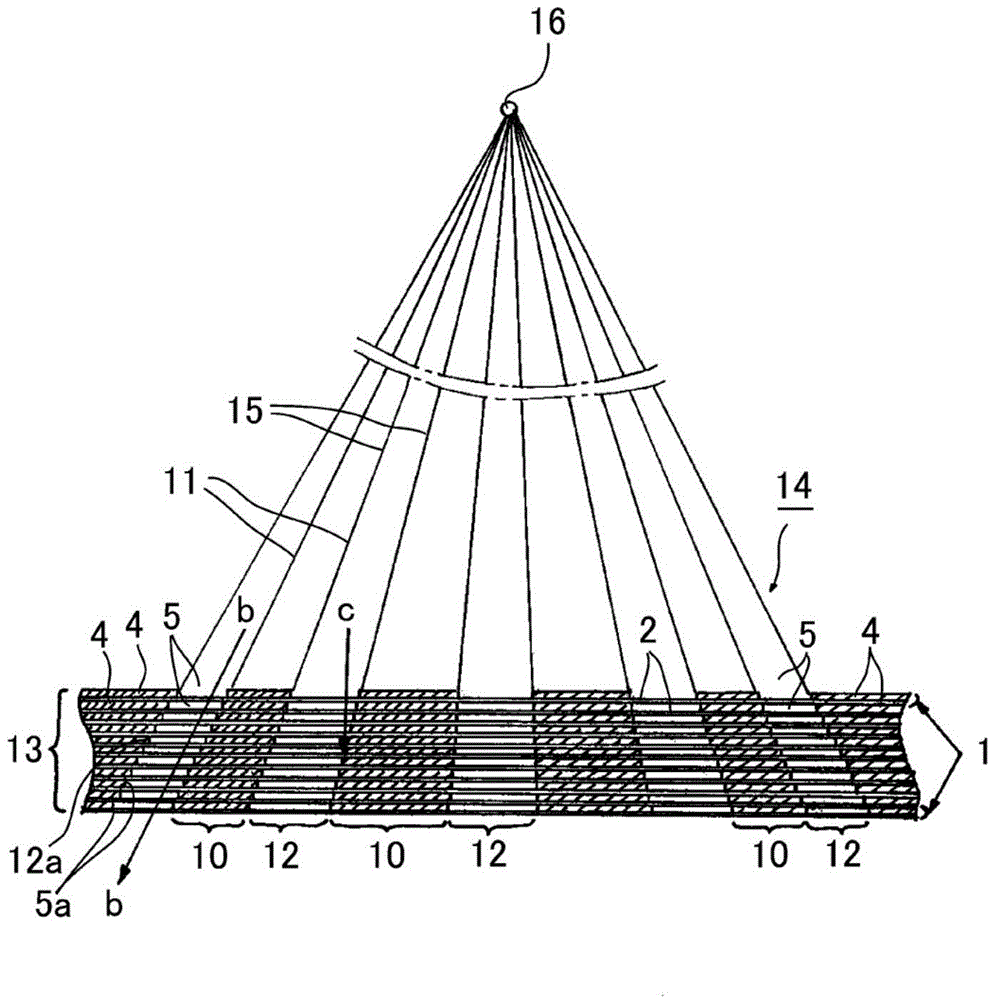

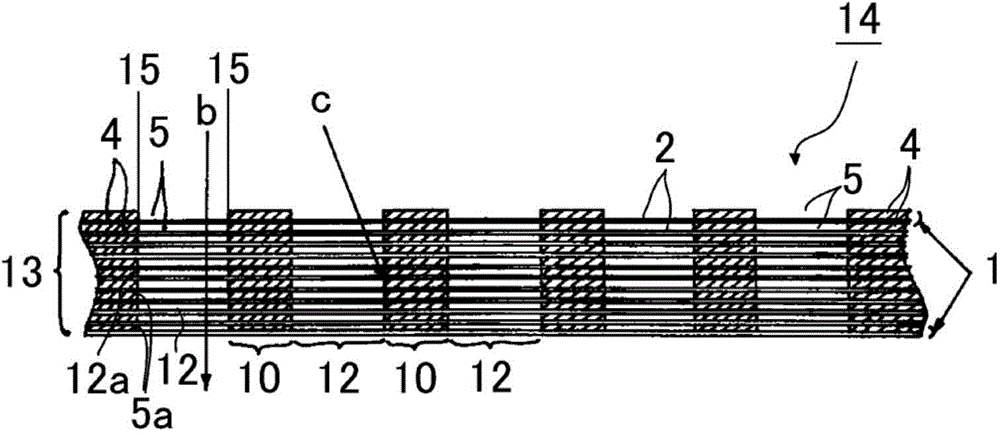

[0153] figure 1 It is a schematic explanatory diagram of the manufacturing process of the printed sheet used as the unit layer used in the laminated X-ray grating according to the present invention.

[0154] The printed sheet 1 is produced by forming a printed layer 3 on the upper surface of the sheet 2 by printing. The printed layer 3 is formed by arranging the X-ray absorber coating layer 4 and the void layer 5 in a predetermined pattern. Both ends of the void layer 5 are referred to as void layer ends 5a, 5a, and since the void layer ends 5a, 5a are the same as the coating layer ends 4a, 4a of the X-ray absorber coating layer, they are unified into the void layer end 5a afterwards. , 5a.

[0155] The printing device can be appropriately selected from existing printe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com