Patents

Literature

36results about How to "No stripping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capacitor coating with deep drawing resistant performance and high temperature yellowing resistance and preparation thereof

The invention discloses a non-yellowing capacitor coating at a high temperature having deep drawing resistance performance and a preparation method thereof. The capacitor coating in the invention is prepared from the materials according to the following parts by weight: 20 to 50 parts of hyperbranched polyester resin, 1 to 7 parts of saturated polyester resin, 3 to 12 parts of isocyanate, 0 to 0.5 parts of adhesion promoter, 0 to 0.15 parts of slipping wax, 0 to 0.3 parts of organic tin catalyst, 2.0 to 6.0 parts of resin modifier, 0.07 to 1.0 parts of defoamer, 0.15 to 0.20 parts of flatting agent, and 30 to 62 parts of solvents. The hyperbranched polyester resin, saturated polyester resin and isocyanate are put into a container so as to prepare a mixture after high-speed dispersing; the rest of the materials are then put into the mixture so as to mix homogeneously by medium-speed dispersing, thereby obtaining the non-yellowing capacitor coating at a high temperature having deep drawing resistance performance. The capacitor in the invention has the characteristics of deep drawing resistance, good percentage elongation of coating film and no yellowing at a high temperature.

Owner:清远慧谷新材料技术有限公司

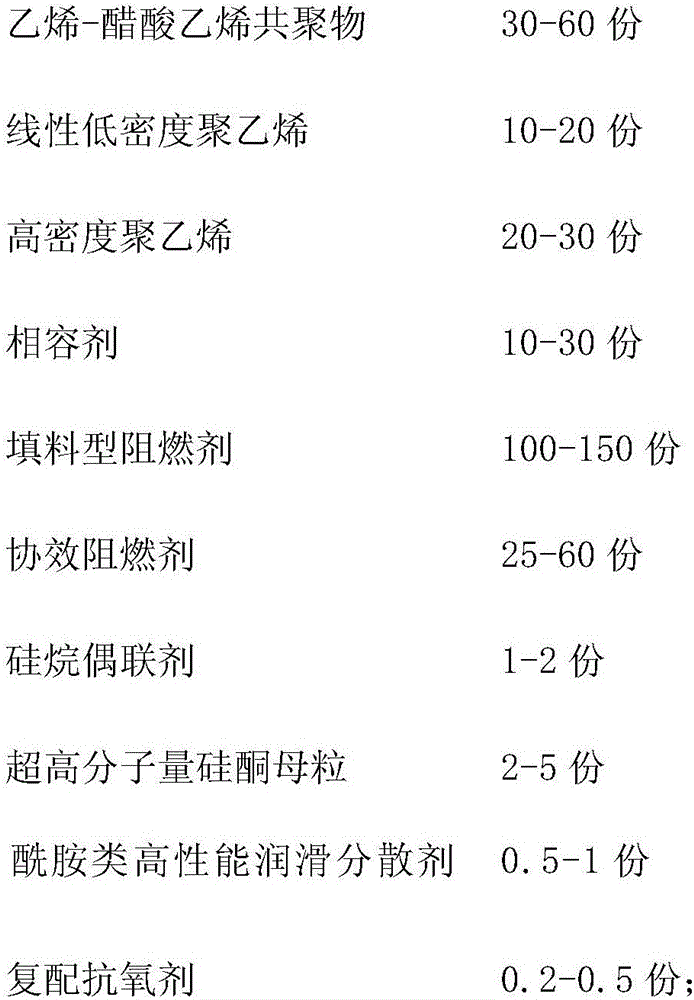

High-speed low-shrink low-smoke zero-halogen tight-buffered material used for 4G optical cable and preparation method of high-speed low-shrink low-smoke zero-halogen tight-buffered material

ActiveCN103897256AHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

The invention discloses a high-speed low-shrink low-smoke zero-halogen tight-buffered material used for a 4G optical cable and a preparation method of the high-speed low-shrink low-smoke zero-halogen tight-buffered material. The tight-buffered material is composed of the following raw materials in parts by weight: 30-60 parts of ethylene-vinyl acetate copolymer, 10-20 parts of linear low density polyethylene, 20-30 parts of high density polyethylene, 10-30 parts of compatilizer, 100-150 parts of filler-type flame retardant, 25-60 parts of synergistic flame retardant, 1-2 parts of silane coupling agent, 2-5 parts of ultra-high molecular weight silicone master batch, 0.5-1 part of amides high-performance lubrication dispersant and 0.2-0.5 part of compound antioxygen through stirring, mixing and extruding steps. The tight-buffered material prepared by elaborate formula selection and processing is low in shrinking percentage, strong in rigidity, high in hardness, high in extrusion molding speed, low in rejection rate and good in high / low temperature cycling resistance. When the tight-buffered material is processed, die orifice stacking and salivation are less, the surface of the optical cable is smooth, fine and particle-free, and the tight-buffered material is easy to peel.

Owner:JIANGSU LINRY NEW MSTAR TECH

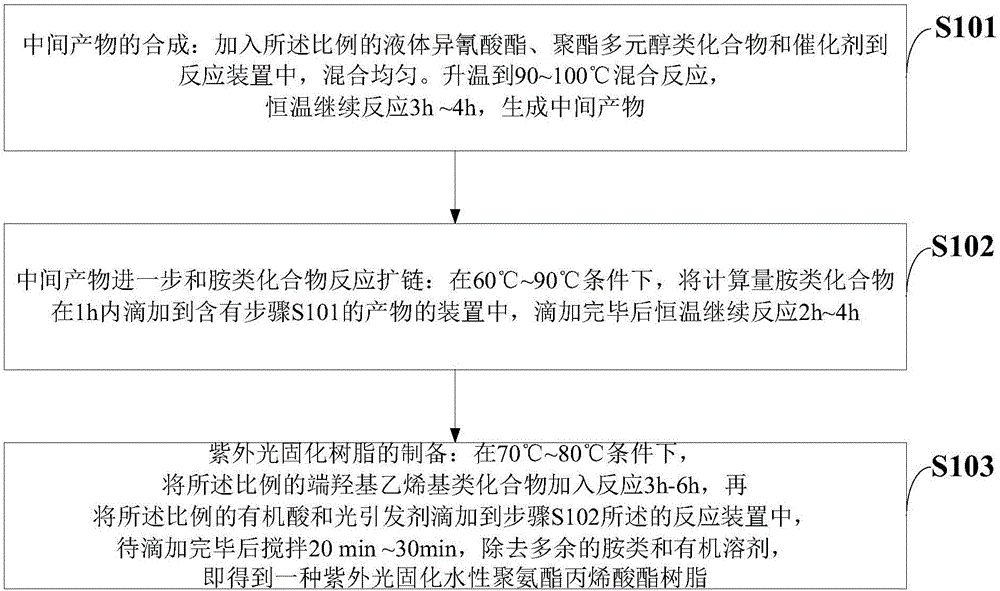

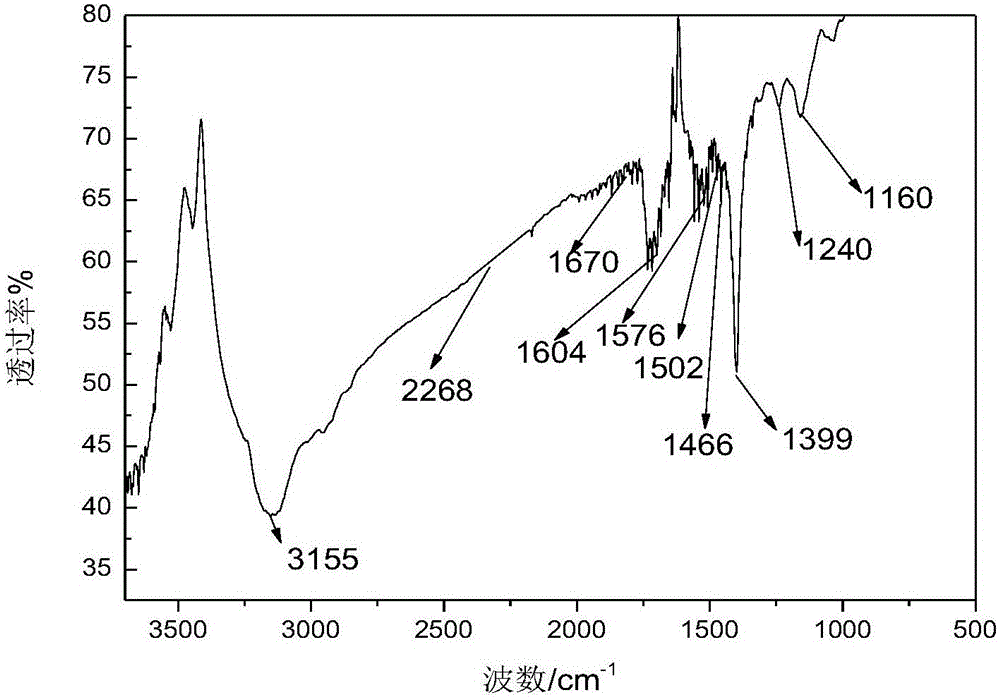

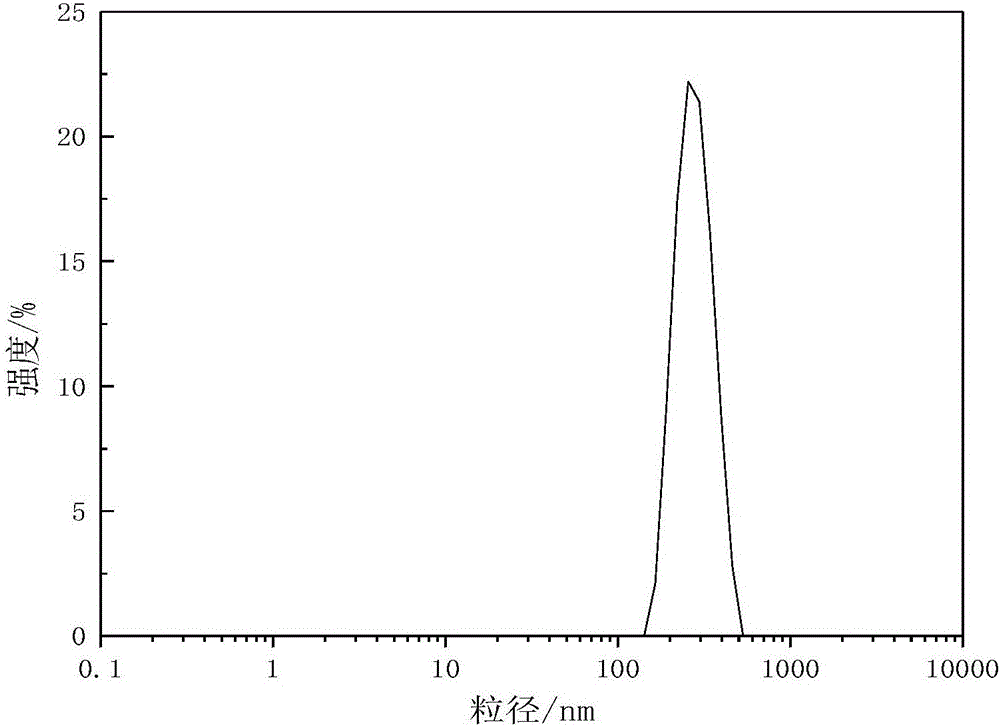

Polyurethane-acrylate cathodic electrophoretic coating material, preparation method therefor and application of polyurethane-acrylate cathodic electrophoretic coating material

InactiveCN106634525AGood emulsificationReduce moisture contentElectrophoretic coatingsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a polyurethane-acrylate cathodic electrophoretic coating material, a preparation method therefor and an application of the polyurethane-acrylate cathodic electrophoretic coating material. The coating material is prepared from the ingredients in percentage by mass: 8% to 17% of amine compound, 10% to 40% of polyisocyanate, 7% to 36% of polyester polyol compound, 0.1% to 0.6% of catalyst, 9.5% to 38% of hydroxyl-terminated vinyl compound, 2% to 7% of organic acid, 2% to 6% of photoinitiator and 0.01% to 1% of leveling agent. According to the method disclosed by the invention, the preparation process is simple, polyurethane acrylate resin further has a good emulsifying property, the cathodic electrophoretic emulsion coating material prepared from the resin has the characteristic of convenience in construction, and a coating film is low in moisture content, is insoluble in water, is free of sagging, is free of dripping and is free of a stripping phenomenon after the electrophoretic coating material is subjected to electrophoresis. According to the electrophoretic coating material disclosed by the invention, the coating film is very uniform and plump and is high in adhesive power, good in leveling property and good in chemical resistance, and the ornamental performance and corrosion resistance are improved.

Owner:东莞市霖辉金属表面处理材料有限公司 +1

Insulation stretch resistant coating, preparation method and application thereof

The invention discloses an insulation stretch resistant coating, a preparation method and an application thereof. The coating comprises the following components of 15-35 parts of a polyester resin A, 5-25 parts of a polyester resin B, 3.5-5 parts of an amino resin, 0-0.5 part of an adhesion promoter, 0.1-0.2 part of a slip additive, 2.5-4 parts of a surface modification agent, 0.1-0.2 part of an antifoaming agent, 0.1-0.2 part of a flatting agent and 50-55 parts of an organic solvent. The method firstly mixing the polyester resin A, the polyester resin B, the amino resin and the organic solvent, and then adding and evenly mixing the adhesion promoter, the surface modification agent, the slip additive, a catalyst, the antifoaming agent and the flatting agent to obtain the insulation stretch resistant coating. The insulation stretch resistant coating is free from yellowing after the coating is roasted for 3 minutes at the temperature of 270 DEG C and capable of resisting high voltage of 1050V; the appearance of a capacitor paint film which is formed by deep-draw is flawless; the paint film is free from dissolution after-tack when soaked in carbon tetrachloride for 2 hours; and the paint film at the position of a notch of the capacitor is free from peeling off and foaming when the capacitor is cooked at the temperature of 100 DEG C for 30 minutes. Accordingly, the coating is wide in application prospect in electronic products.

Owner:清远慧谷新材料技术有限公司

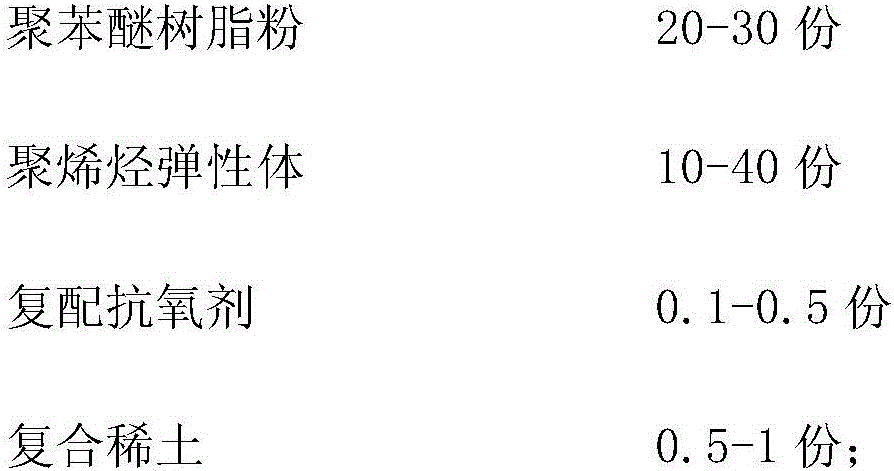

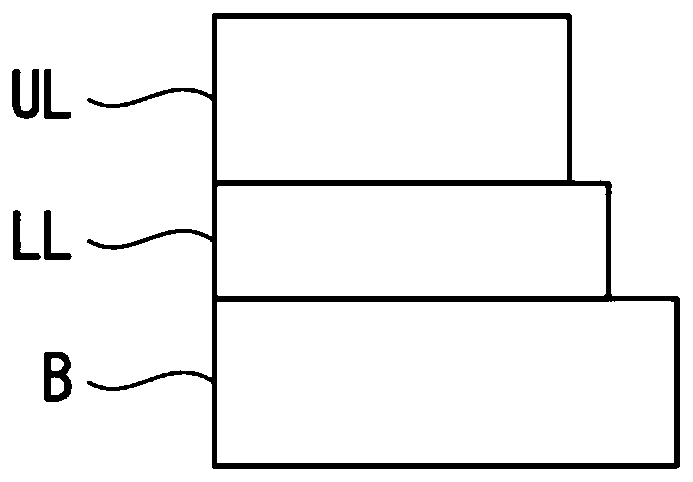

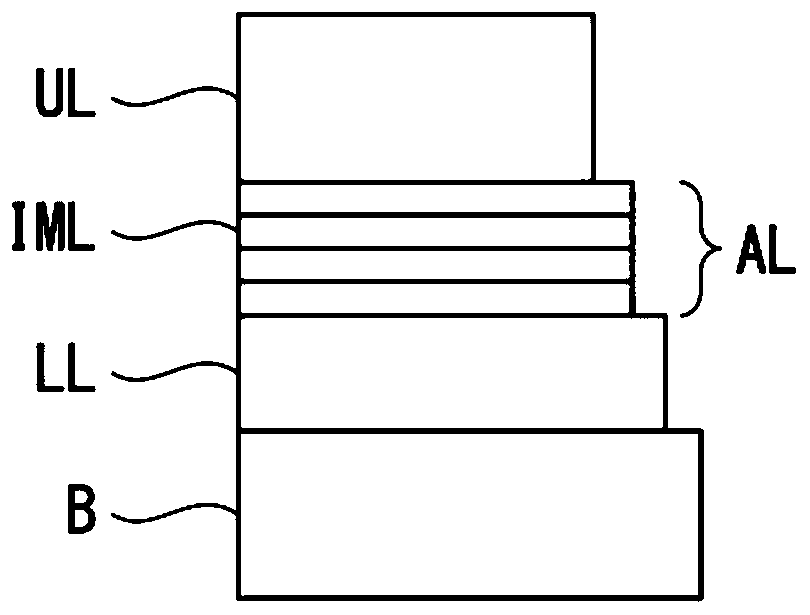

Environmental-friendly protection film for automobile

ActiveCN101928527AImprove bindingNo strippingFilm/foil adhesivesSynthetic resin layered productsSolventCorrosion

The invention provides an environmental-friendly protection film for an automobile. The environmental-friendly protection film is produced by co-extruding and casting an external layer, a middle layer and a bonding layer according to a certain thickness proportion to obtain a white protection film with the thickness of 40 to 100 micron. The environmental-friendly protection film mainly has the functions of dust prevention, mechanical damage prevention, ultraviolet prevention, bird dung pollution prevention, scraping prevention, oil pollution prevention, acid and alkali corrosion resistance, solvent corrosion resistance and the like.

Owner:安徽双津实业有限公司

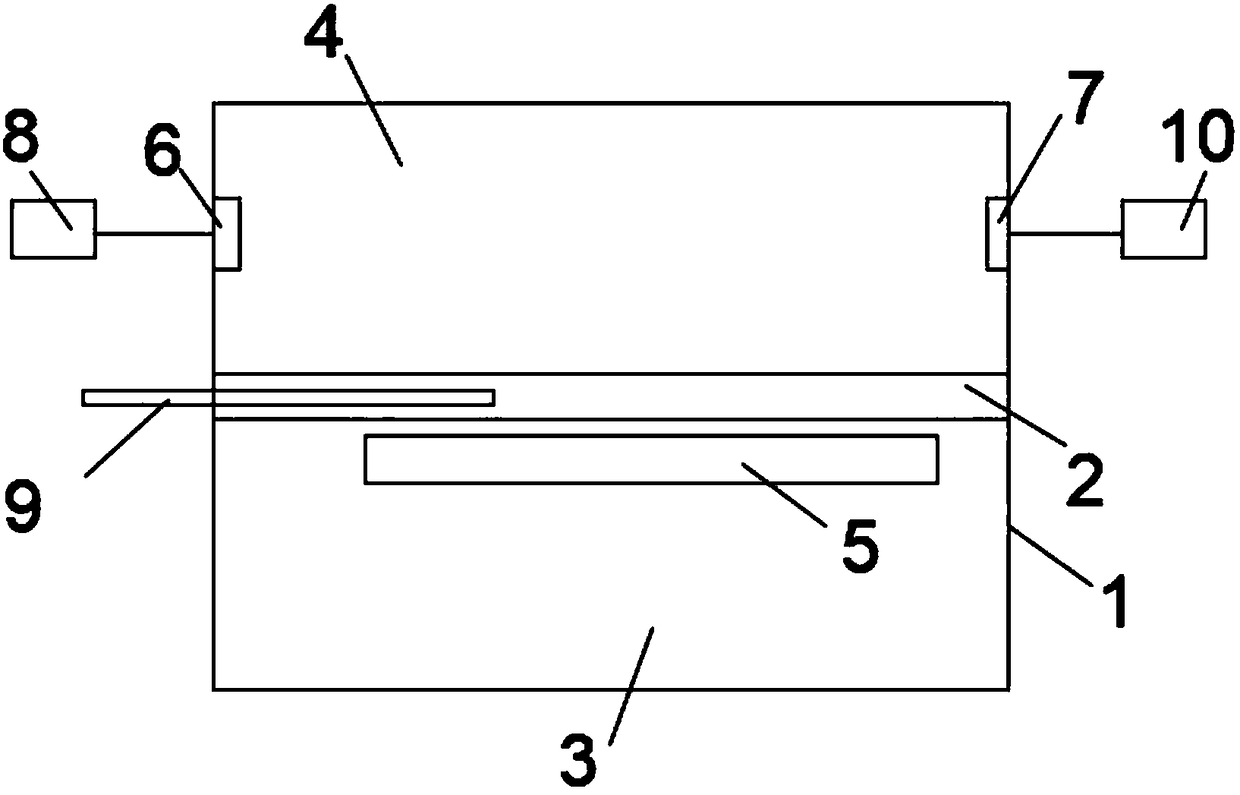

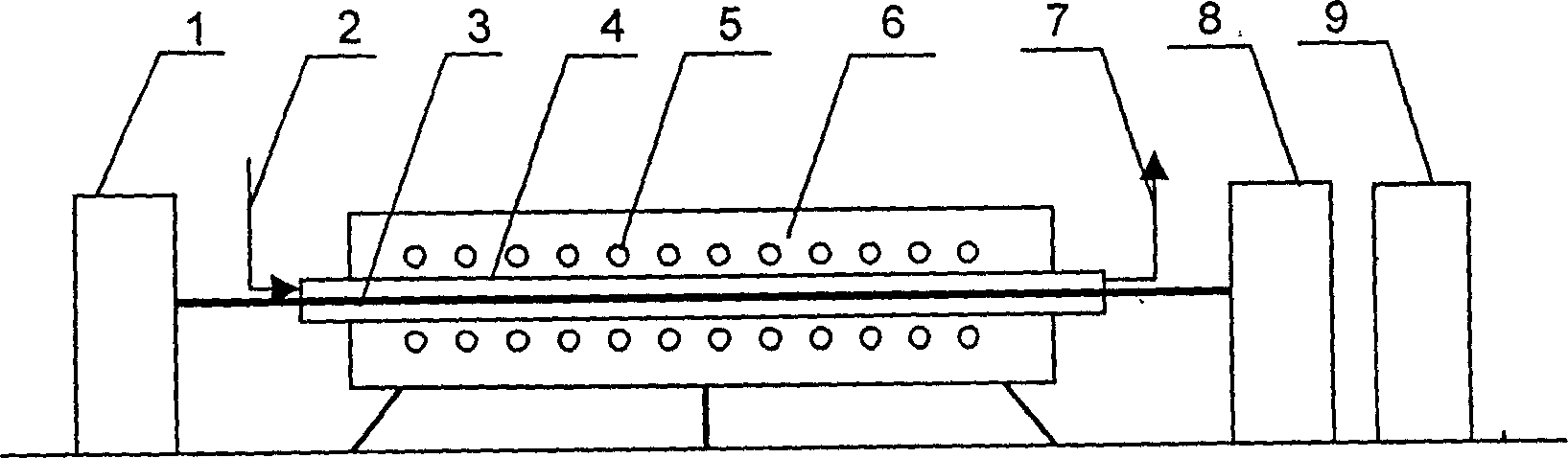

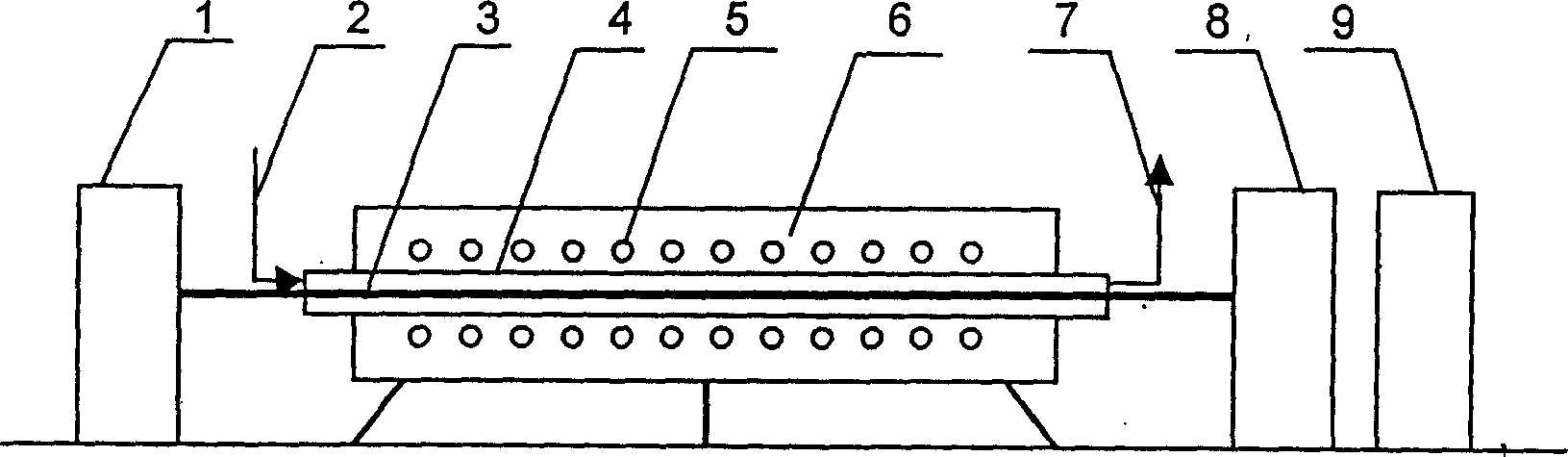

Preparation apparatus and preparation method of polyimide thick membrane or polyimide ultrathick membrane

The invention discloses a preparation apparatus and preparation method of a polyimide thick membrane or a polyimide ultrathick membrane, which belongs to the technical field of polyimide membranes. The preparation apparatus comprises a shell, wherein a metal plate parallel to the bottom surface of the shell is arranged inside the shell, the interior of the shell is divided by the metal plate intotwo independent heating cavities and a cooling cavity located on the upper portion of the heating cavity, the top of the heating cavity is provided with a heating pipe parallel to the metal plate, twoside surfaces of the cooling cavity are respectively provided with an air inlet and an air outlet, the outer side of the shell is provided with an air blower, the air blower is communicated with thecooling cavity by virtue of the air inlet, and a thermocouple is arranged in the middle of the metal plate. The invention also discloses a method for preparing the polyimide thick membrane or the polyimide ultrathick membrane by using the preparation apparatus. By adopting the preparation apparatus and preparation method, the polyimide thick membrane or polyimide ultrathick membrane with thicknessgreater than 50 micrometers can be prepared; and moreover, the structure is simple, and the operation is easy.

Owner:GUANGXI NORMAL UNIV +1

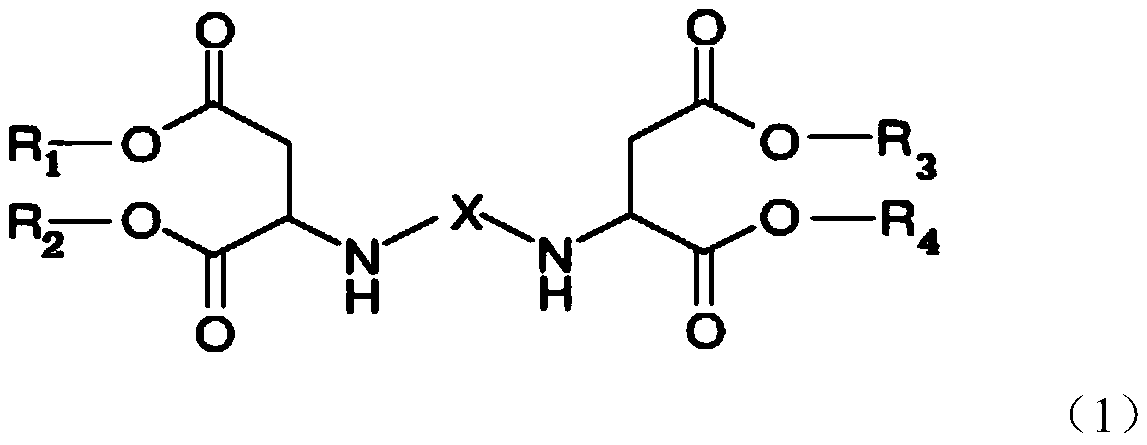

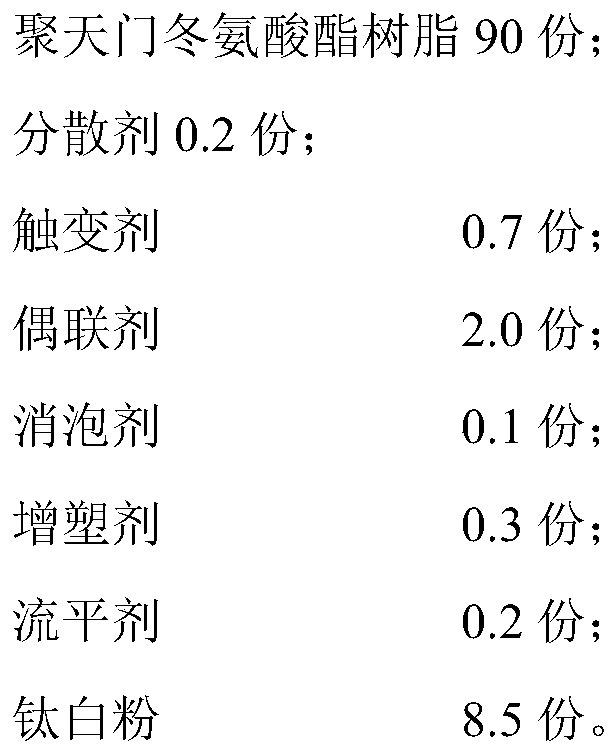

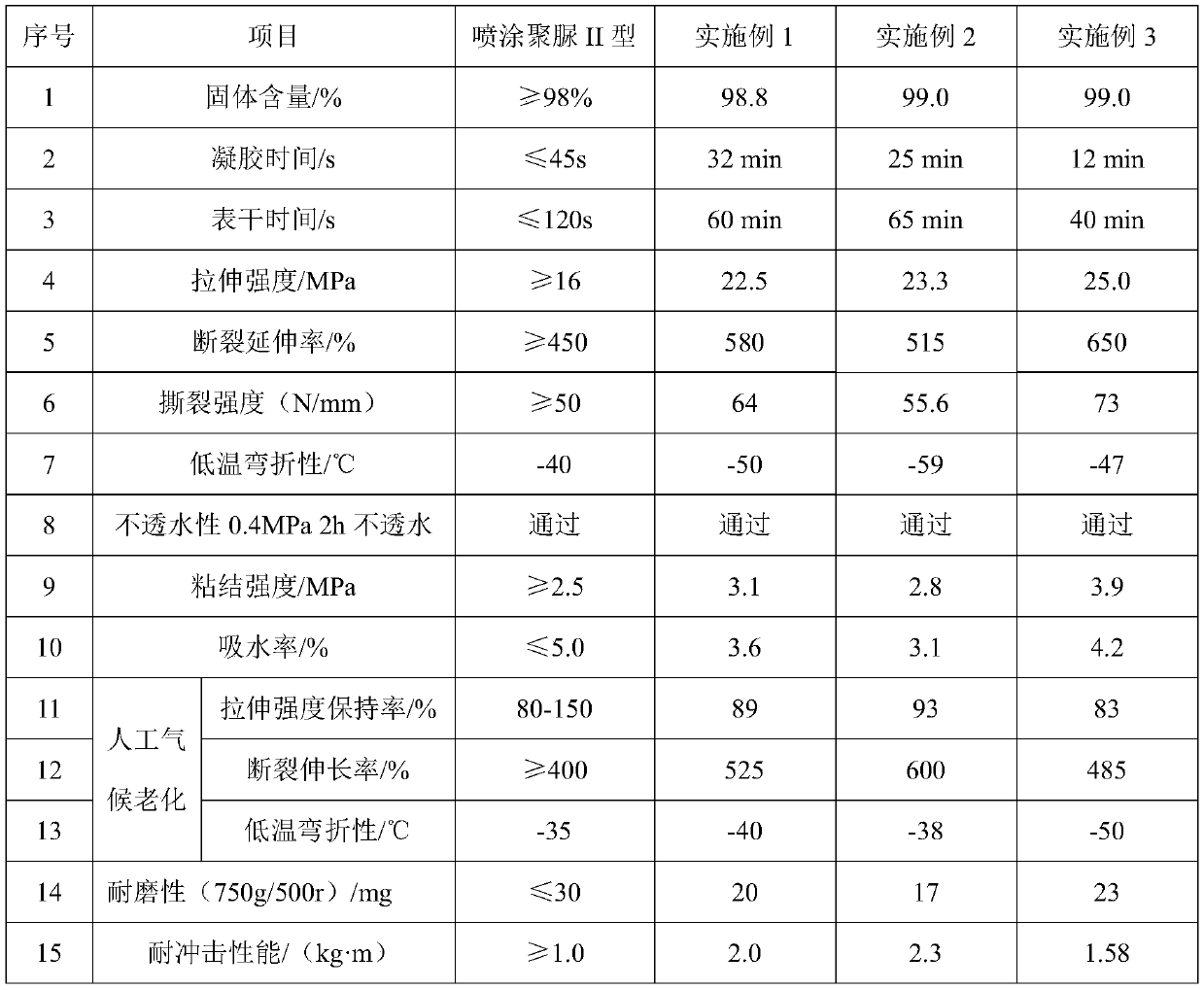

Exposed polyurea waterproof repair coating, and preparation and construction method thereof

InactiveCN110437716AGood weather resistanceGood waterproof and sealing performanceBuilding repairsPolyurea/polyurethane coatingsWeather resistanceHazardous substance

The invention discloses an exposed polyurea waterproof repair coating, and preparation and construction method thereof. The exposed polyurea waterproof repair coating is prepared from a component A and a component B. The component A is prepared from the following components: polyaspartic ester resin, polyether polyamine, a dispersant, a plasticizer, a defoamer, a coupling agent, solid filler, a thixotropic agent and a leveling agent; the component B is a curing agent; and the mass ratio of the component A to the component B is (1.5-3):1. The invention further discloses the preparation method of the waterproof repair coating and the construction method of the waterproof repair coating at the same time. The exposed polyurea waterproof repair coating has excellent weather resistance and waterproof sealing performance, no hazardous substances volatilization, no yellowing, no peeling and firm bonding. When the coating is used for construction, a base surface does not need to be beaten and chiseled, the coating can be sprayed or scraped manually, is fast and efficient, waterproof thoroughly and durable, environmentally safe, and can be used in new waterproofing projects and building repair projects.

Owner:大禹九鼎新材料科技有限公司

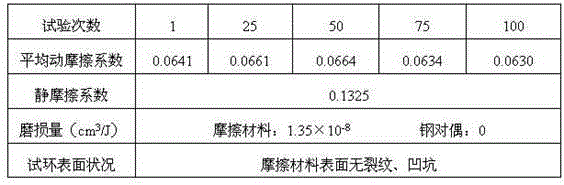

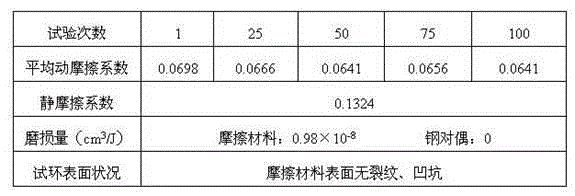

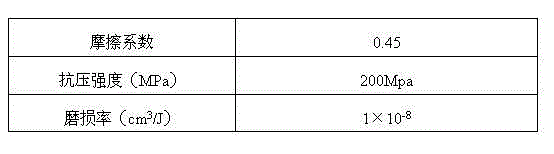

Steel-backing non-electroplating copper alloy based friction material and preparation method and application for friction piece

The invention provides a steel-backing non-electroplating copper alloy based friction material and a preparation method and application for a friction piece. The copper alloy based friction material is composed of, by weight, 50%-84% of copper powder, 3%-15% of metallic bond, 5%-20% of friction modifier and 5%-15% of abrasion-resistant agent. The invention further provides the method for preparing the steel-backing non-electroplating copper alloy based friction piece through the friction material and the application of the friction piece. The manufacturing cost of the prepared steel-backing non-electroplating copper alloy based friction piece is far lower than that of a steel-backing electroplating copper alloy based friction piece. The copper alloy based friction layer is firmly bonded to steel backing and free of cracks, stripping and layering are avoided, and the technical requirements and the market requirements are completely met, so that not only is the environment protected, but also resources are saved.

Owner:CHANGSHA JIANMING ENG MACHINERY FRICTION MATERIALS CO LTD

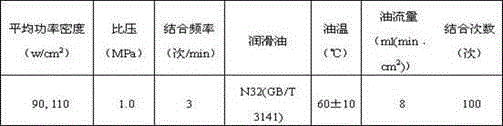

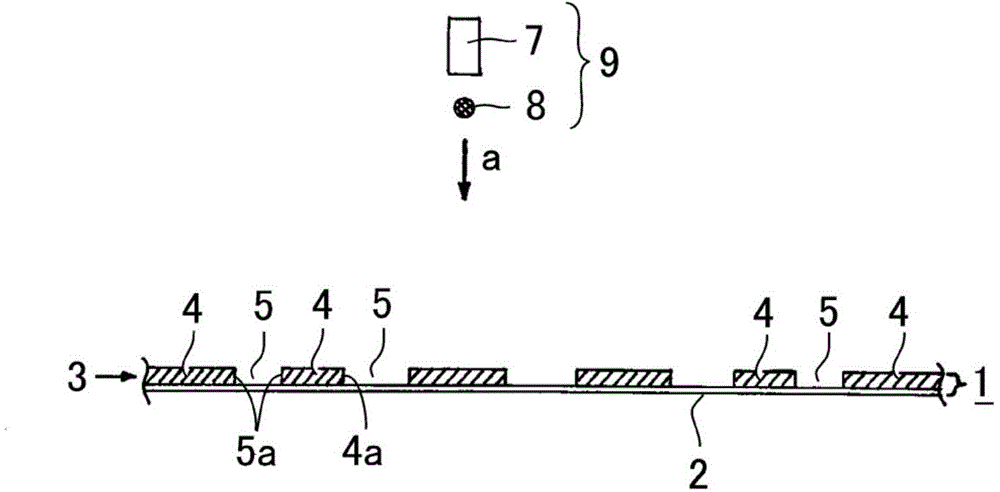

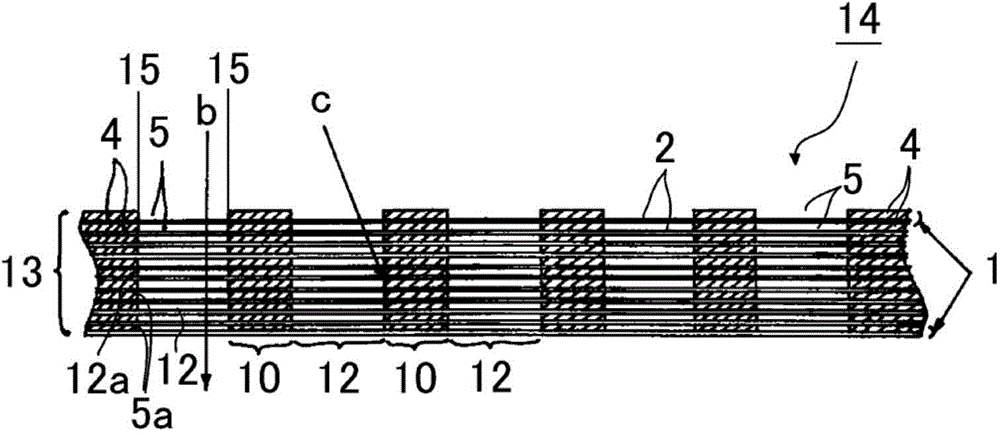

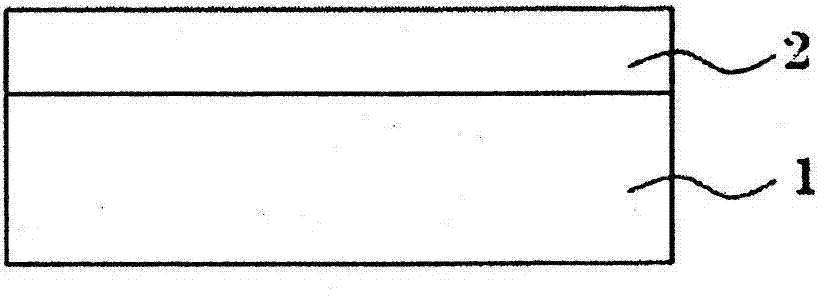

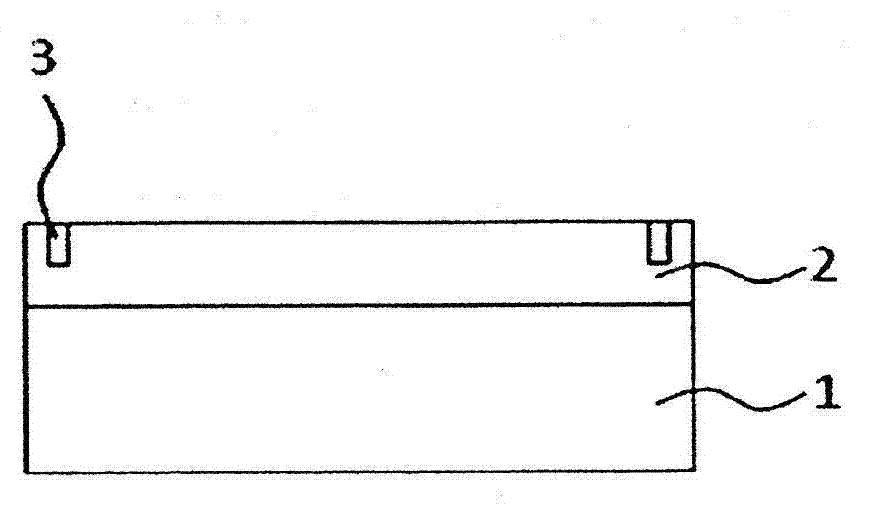

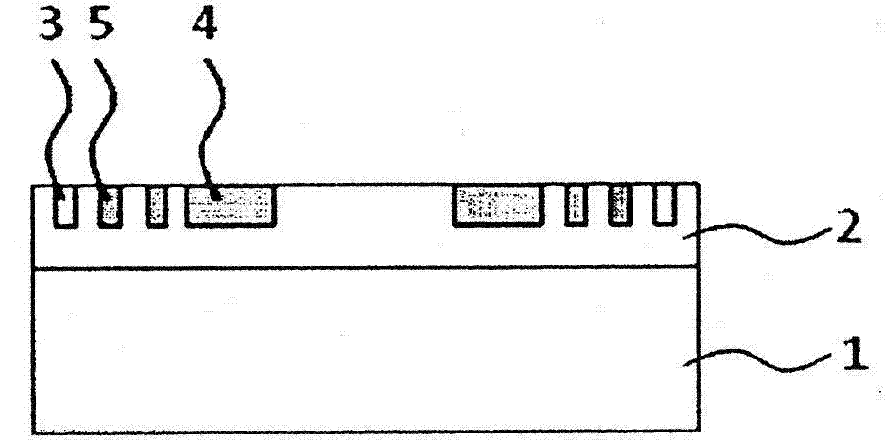

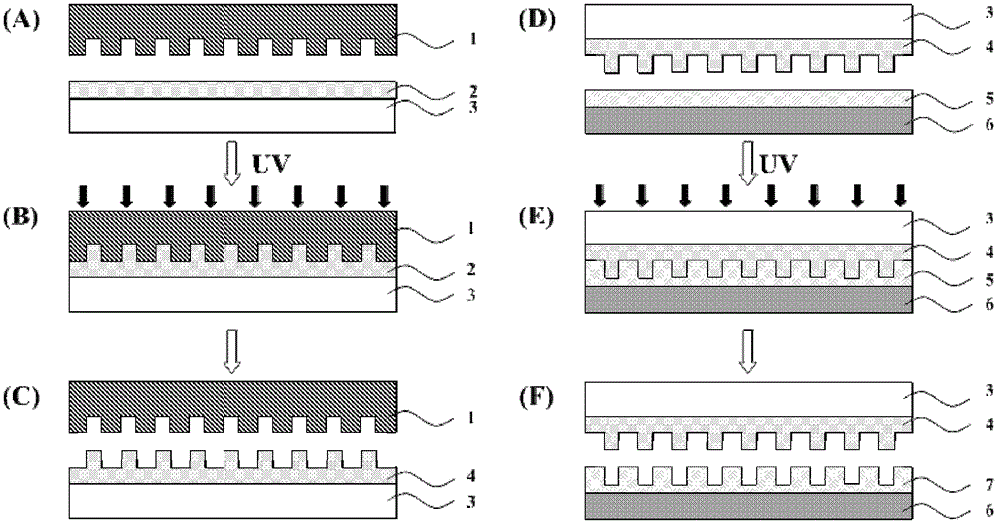

Laminated type X-ray filter grating, and manufacturing device and manufacturing method thereof

InactiveCN104575657AWith strengthMaintain stabilityRadiation/particle handlingRadiation diagnosticsX-ray filterGrating

The invention provides a laminated type X-ray filter grating with shape keeping property, rigidity, and durability. The laminated type X-ray filter grating is characterized in that printed sheets (1) formed on sheets (2) with X-ray transmissivity and containing printing layers (3) of specified patterns of X-ray absorption coating layers (4) and gap layers (5) is regarded as the unit layer, a plurality of printed sheets (1) are formed by a printed sheet laminating body (13) laminated by the sheets (2) and the printing layers (3) in an alternative manner in the lamination direction, a plurality of X-ray absorption coating layers (4) laminated in the vertical manner and clamping the sheets (2) form an X-ray absorption portion (10), and a plurality of gap layers (5) laminated in the vertical direction and clamping the sheets (2) form an X-ray transmission portion (12). Therefore, the top can be provided with an upper side plate (20) with the X-ray transmissivity, and the bottom can be provided with a lower side plate (18) with the X-ray transmissivity.

Owner:FUJIKIN INC

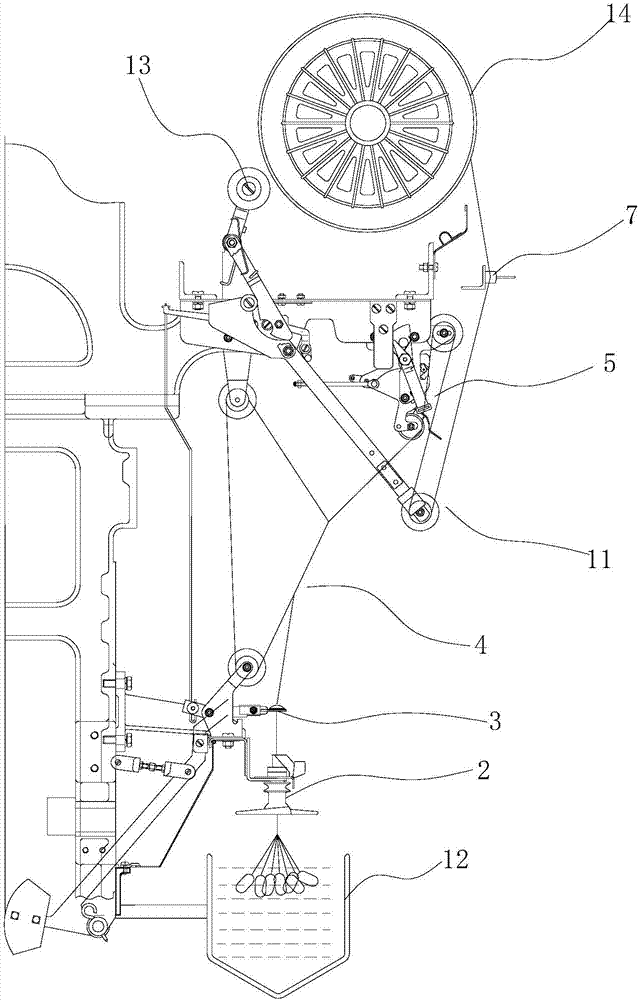

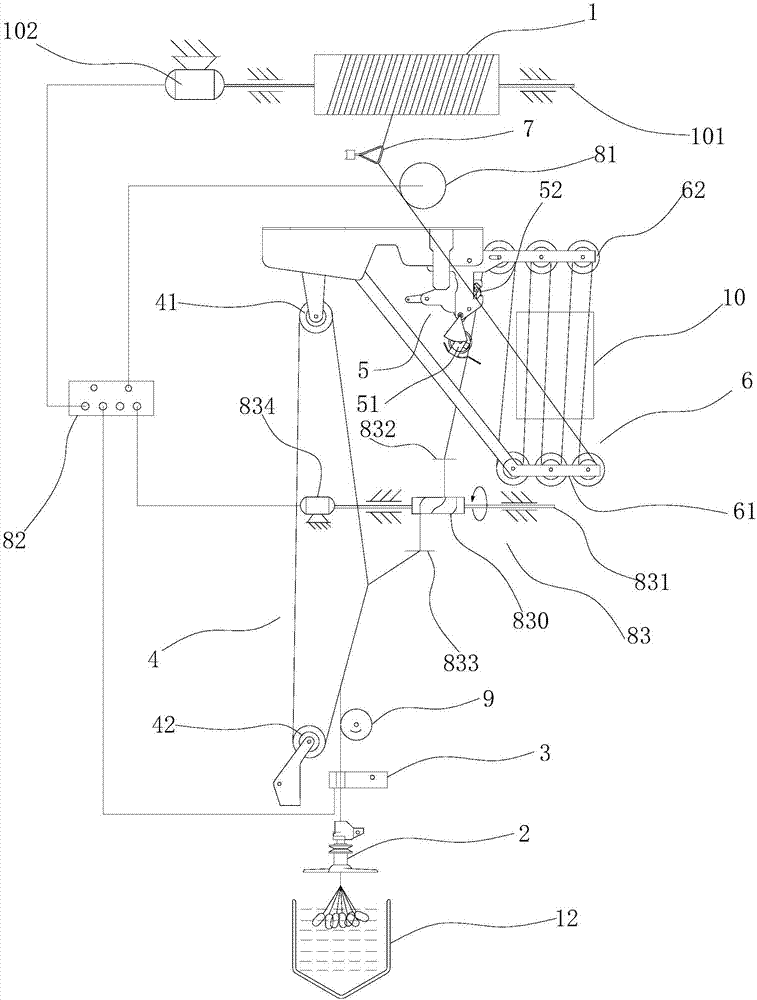

Efficient silk making device

ActiveCN108004599AIncrease productivitySimple structureSilk reelingTextile/flexible product manufactureMotor driveElectric machinery

The invention relates to the technical field of silk making, in particular to an efficient silk making device comprising a plurality of silk making units which are independent mutually. Each silk making unit is provided with a regulating system, a unit barrel and a winding motor driving the unit barrel to rotate, each regulating system comprises a detector for detecting silk strip tension, a signal processor and an adjusting structure, each adjusting structure is arranged between a sheath twisting structure and an exploring structure and comprises a silk guide roller, an upper silk guide button, a lower silk guide button and a rotating motor, a roller shaft of each silk guide roller is connected with an output shaft of the corresponding rotating motor, and each signal processor is connected with the corresponding rotating motor, the corresponding winding motor and the corresponding detector. When silk strip tension is too small, the rotating motor reduces rotating speed of the silk guide rollers to decrease silk strip winding speed, loose winding of silk strips is avoided, and the silk strip tension is increased gradually; when the silk strip tension is too large, the rotating motor increases the rotating speed of the silk guide rollers to avoid the silk strips being wound too tightly, and the silk strip tension is lowered gradually; a silk barrel is loose outside and tight inside, so that shaping is good, and phenomena of silk sliding, silk embedding and silk breaking are avoided.

Owner:ZHEJIANG SCI-TECH UNIV +2

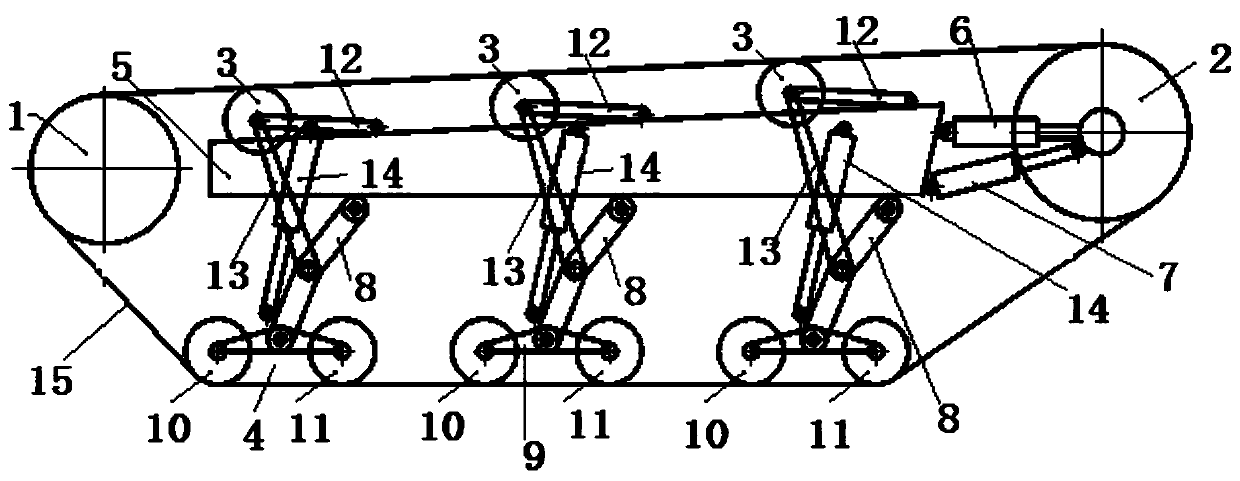

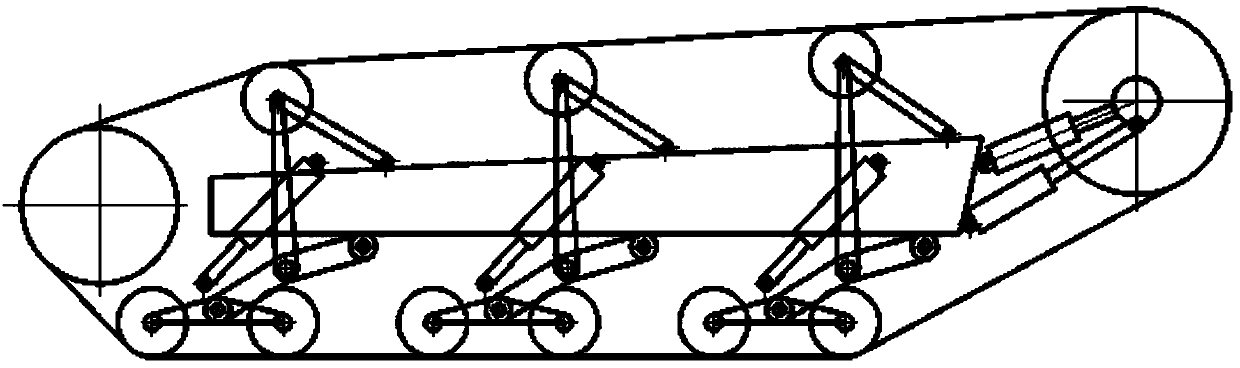

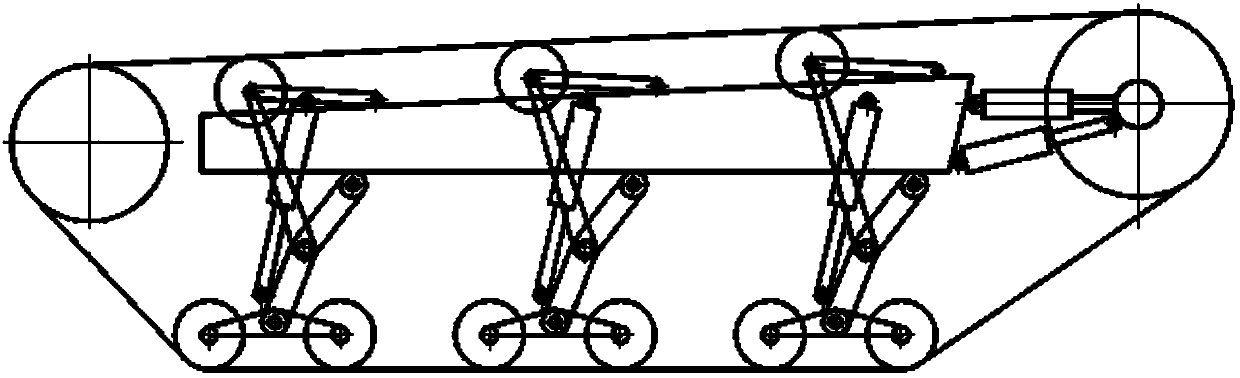

Crawler belt tensioning device

The invention discloses a crawler belt tensioning device. The crawler belt tensioning device comprises a driving wheel and an induction wheel, the driving wheel and the induction wheel are located atthe two ends of a vehicle body truss respectively, the driving wheel is located at the end, with a smaller diameter, of the vehicle body truss, and the induction wheel is hinged to the end, with a larger diameter, of the vehicle body truss through a first connecting rod. A first air spring is movably connected between the induction wheel and the vehicle body truss, and the first air spring is located at the lower end of the first connecting rod. The lower portion of the vehicle body truss is movably connected to a load-bearing wheel group, the load-bearing wheel group is movably connected to abelt pulley, and the belt pulley is hinged to the upper portion of the vehicle body truss. A crawler belt sequentially passes through the driving wheel, the belt pulley, the induction wheel and the load-bearing wheel group to form a closed structure. As the crawler belt tensioning device is arranged, when a crawler belt vehicle passes through various obstacles, the crawler belt is tensioned in real time so that the belt does not come off or break.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-performance thermal-conduction wire and preparation method thereof

ActiveCN107599538AHigh thermal conductivityGood heat and cold resistanceLayered productsSolventLow Mass

The invention discloses a high-performance thermal-conduction wire and a preparation method thereof. The thermal-conduction wire is composed of a flexible graphene thermal-conduction film and a base material. The flexible graphene thermal-conduction film is composed of the following raw materials (by weight): 5-30% of graphene oxide, 60-85% of a solvent, 1-5% of a wetting agent, 1-3% of an auxiliary agent, 5-10% of a surfactant and 1-4% of an adhesive. Heat conductivity coefficient of the thermal-conduction wire is 783 W / (m.K) and above. The graphene-composite thermal-conduction wire achieves783 W / (m.K) and above. Equivalent diameter of the thermal-conduction material can be controlled according to requirements. The thermal-conduction wire has good heat-cold resistance and also has characteristics of flexibility, small size and low mass.

Owner:SOUTH CHINA UNIV OF TECH +1

Steel-backing non-electroplating iron alloy based friction material and preparation method and application for friction piece

InactiveCN105436497AReduce manufacturing costWide variety of sourcesOther chemical processesIron powderFriction modifier

The invention provides a steel-backing non-electroplating iron alloy based friction material and a preparation method and application for a friction piece. The iron alloy based friction material is composed of, by weight, 60%-84% of iron powder, 1%-10% of metallic bond, 12%-30% of friction modifier and 3%-16% of abrasion-resistant agent. The invention further provides the method for preparing the steel-backing non-electroplating iron alloy based friction piece through the friction material and the application of the prepared friction piece. The manufacturing cost of the prepared steel-backing non-electroplating iron alloy based friction piece is far lower than that of a steel-backing electroplating iron alloy based friction piece. The iron alloy based friction layer is firmly bonded to steel backing and free of cracks, stripping and layering are avoided, and the technical requirements and the market requirements are completely met, so that not only is the environment protected, but also resources are saved.

Owner:CHANGSHA JIANMING ENG MACHINERY FRICTION MATERIALS CO LTD

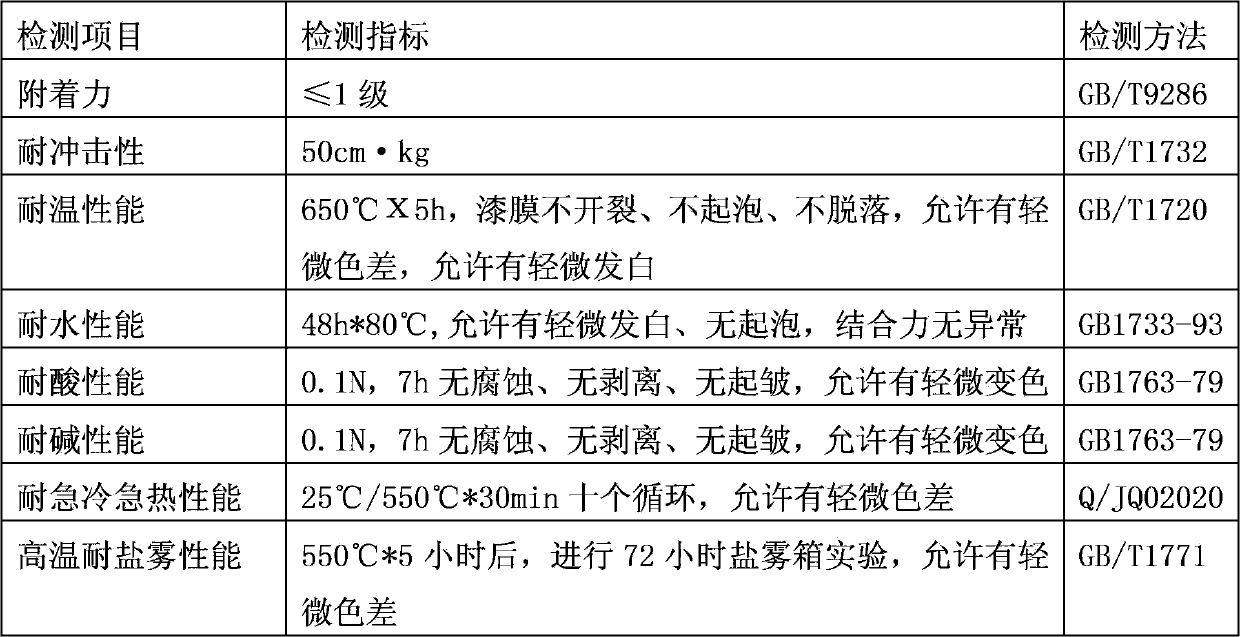

High-temperature-resistant anticorrosive paint and preparation method thereof

InactiveCN102719191BImprove bindingGood color retentionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester

The invention discloses high-temperature-resistant anticorrosive paint and a preparation method thereof. The paint comprises finishing paint and a primer which are matched, wherein calculated by mass percentage, the raw-material formula of the finishing paint comprises the following components: 20-30 percent of polyester modified organic silicon resin, 20-40 percent of filler, 30-50 percent of thinner and 0.5-1 percent of auxiliary agent; the filler is the mixture of glass powder, talcum powder, mica powder and carbon black; the raw-material formula of the primer comprises the following components: 10-20 percent of organic-silicon modified epoxy resin, 10-20 percent of phenolic resin, 20-40 percent of primer filler, 30-50 percent of thinner and 0.5-1 percent of auxiliary agent; and the primer filler is the mixture of iron red, mica powder, talcum powder and glass powder. The fillers adopted by the invention have the performances of acid resistance, alkali resistance, heat resistance, fire resistance, insulation and the like, and the obtained paint has the advantages of good weather resistance, high-temperature resistance, small color difference, good anticorrosive performance, good bonding force and low preparation cost.

Owner:SOUTH CHINA UNIV OF TECH

Method for manufacturing silicon carbide semiconductor device

InactiveCN104303269AImprove efficiencyUniform film thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesMetal foilCarbide

An ohmic electrode (6) of a silicon carbide semiconductor device is produced by forming an ohmic metal film on a silicon carbide substrate (1) by sputtering a target that is formed of a mixture or alloy in which nickel and a metal that reduces the magnetic permeability of nickel and forms a carbide are adjusted to a predetermined composition ratio, and firing the ohmic metal foil by a heat treatment. Consequently, there can be produced an ohmic electrode (6) of a silicon carbide semiconductor device, said ohmic electrode (6) having a uniform thickness and being free from separation, while improving the efficiency of the target.

Owner:FUJI ELECTRIC CO LTD

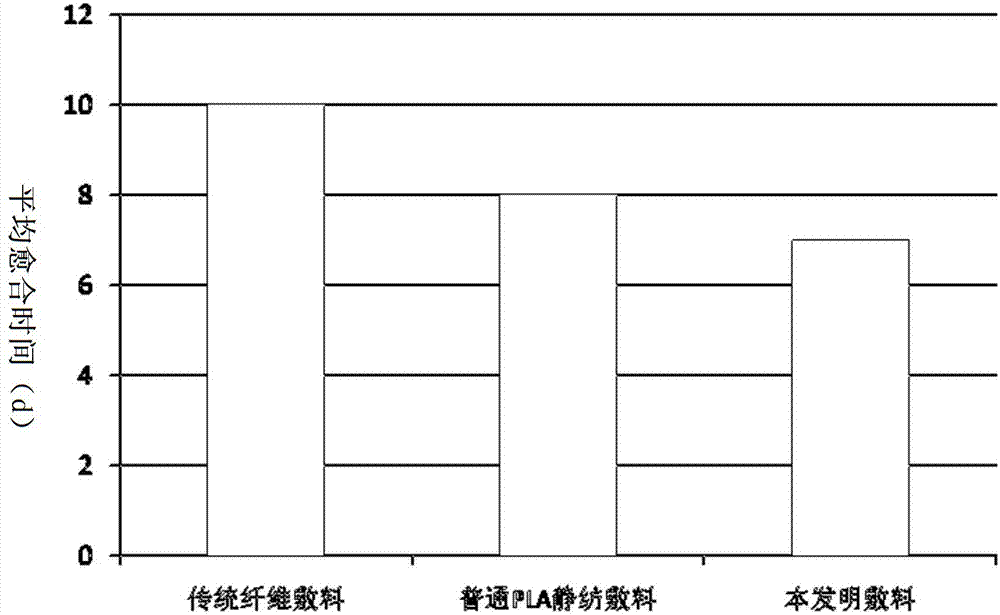

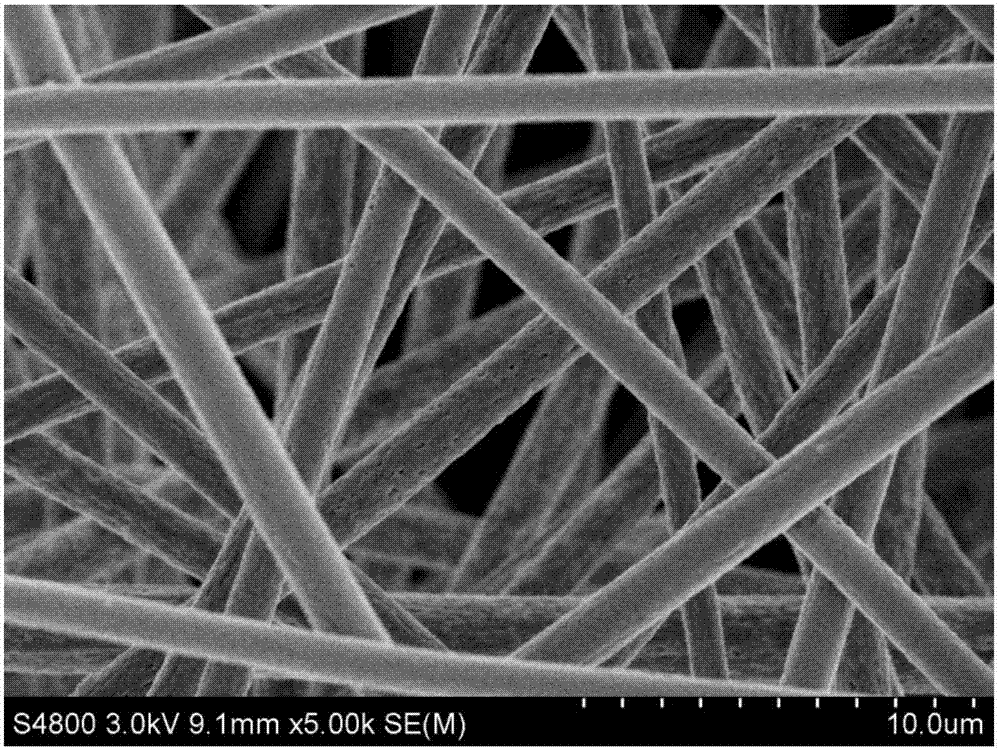

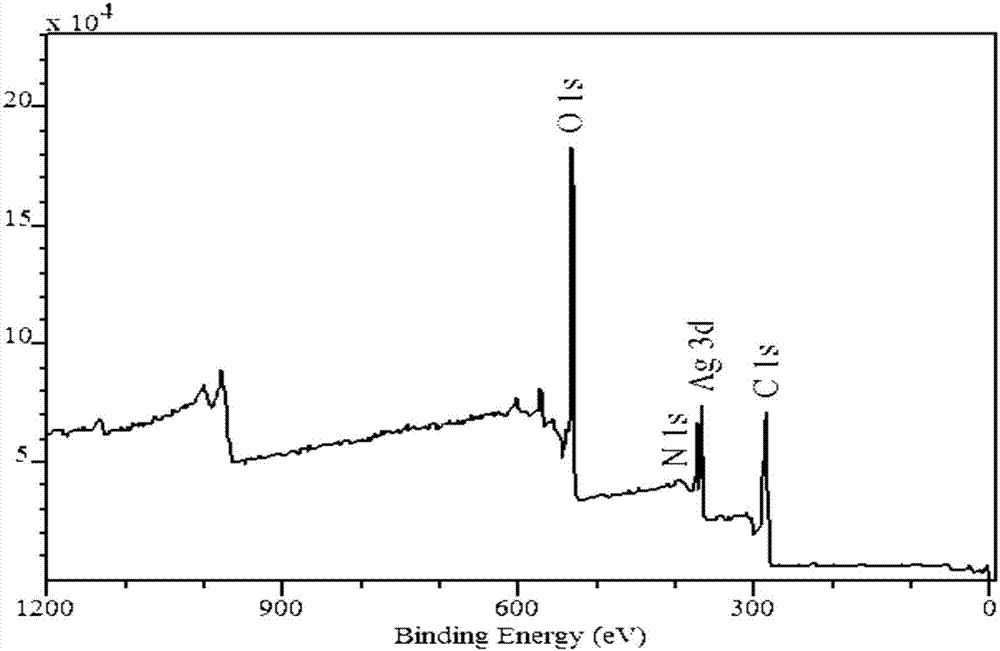

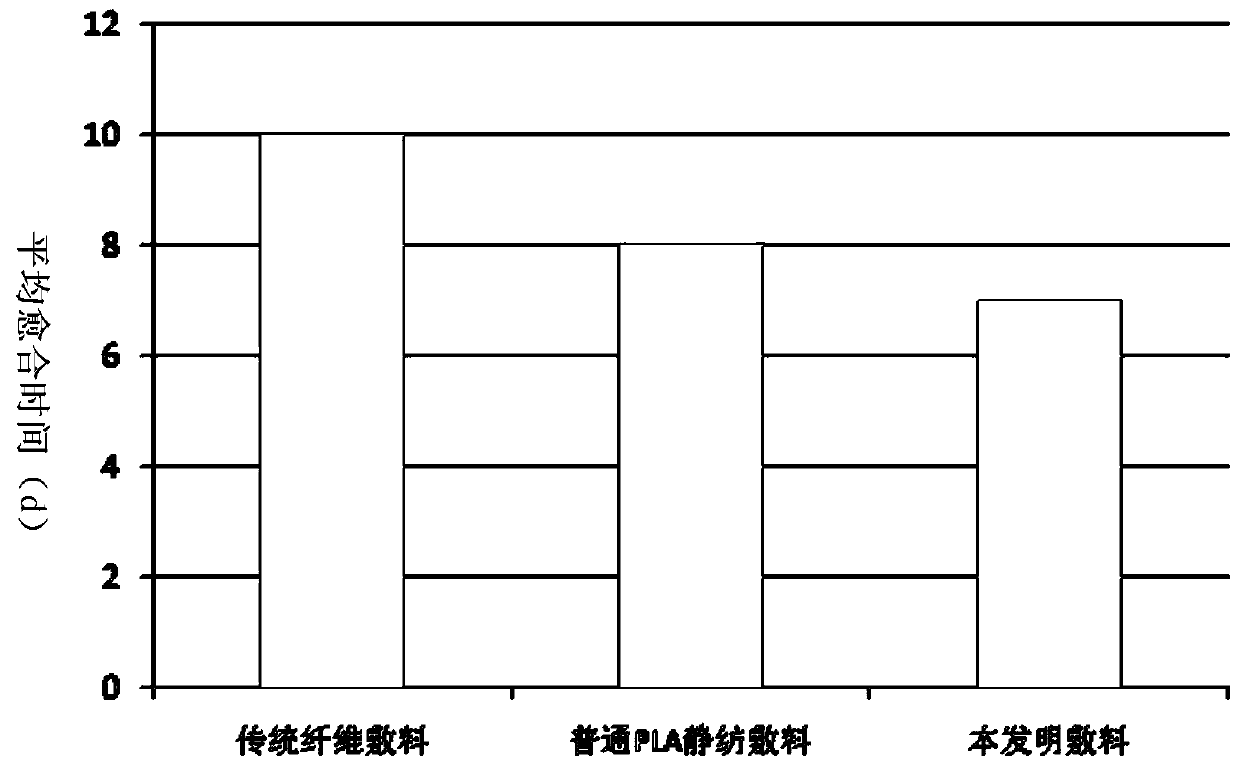

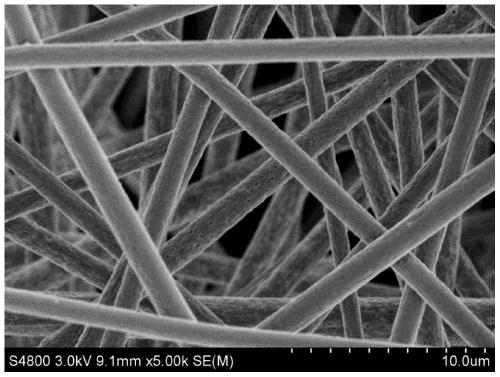

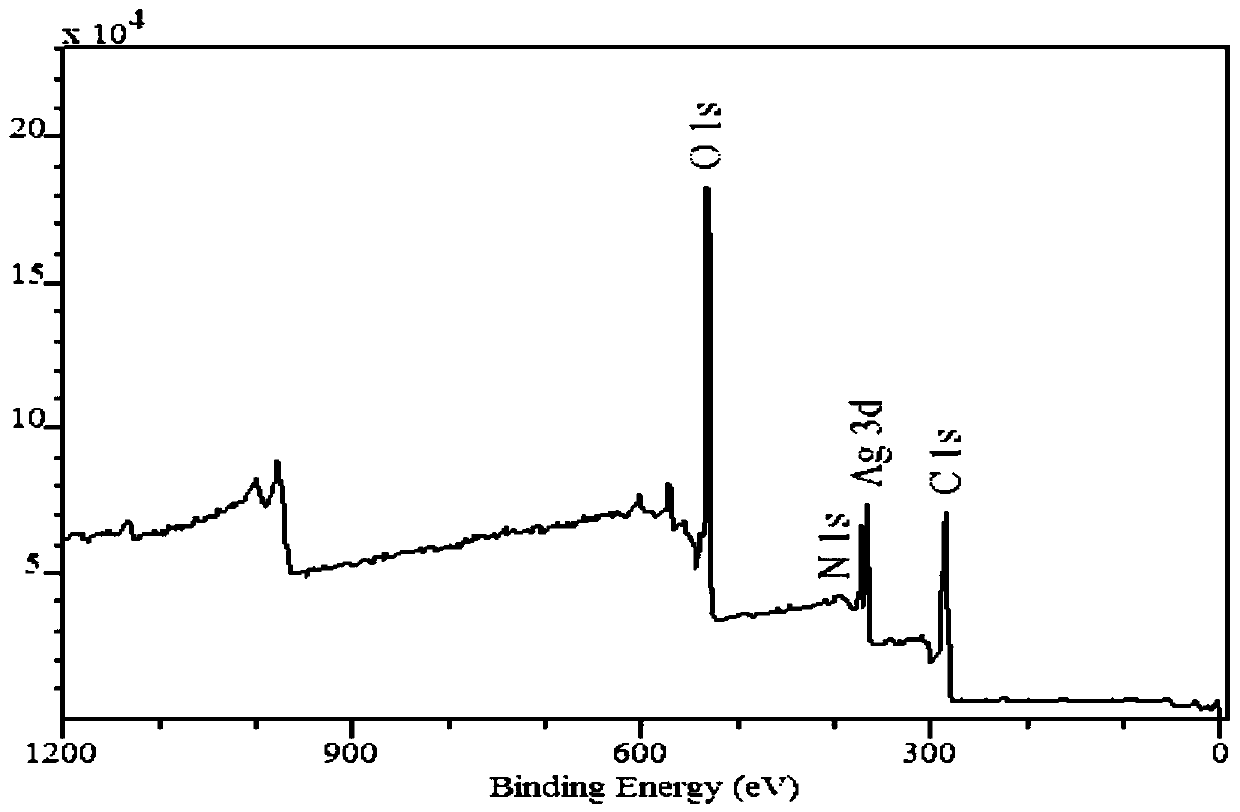

Preparation method for skin adhering type nano-silver ion anti-microbial dressing

The invention discloses a preparation method for skin adhering type nano-silver ion anti-microbial dressing. The method comprises the following steps: mixing the pure solvent chloroform and ethyl alcohol at volume ratio of (1-3):1, and by taking the mixture as a solvent, dissolving the polylactic acid and polyethylene glycol at volume ratio of (1-4):1 in the mass concentration of 8%-20%; adding the acquired mixed solution into an electrostatic spinning device for preparing the dressing; sterilizing the acquired dressing by utilizing a sterilizing method, taking out and airing; andsoaking the aired dressing into a silver nitrate solution, taking out and then airing, thereby acquiring the skin adhering type nano-silver ion anti-microbial dressing. The invention has the advantages that the use is comfortable, no pressure-sensitive adhesive is required for fixing, the problems of poor air permeability, poor adhesion, low fitting degree, adhesion to wound and incapability of isolating from and resisting against bacteria of the traditional medical dressing can be solved, the skin motion and sweat are not influenced in the use process and the dressing is thin and soft, reusable and free from residue on the skin.

Owner:SHAANXI UNIV OF SCI & TECH

Normal-temperature phosphating fluid for drawing steel

The invention discloses a normal-temperature phosphating fluid for drawing steel. The liquid is prepared by nitrate, nitrite, nitroguanidine, molybdate, phosphate, an accelerant and deionized water. The liquid can be used for performing normal-temperature phosphating on the steel for drawing, and can reach a same effect under a relatively-high-temperature phosphating; under the normal temperature, after 3 to 5 minutes, a layer of black, even and compact phosphating film can be formed on the surface of the steel, and the corrosion resistance is tested to be above the national standard. The problems of large high-temperature phosphating liquid consumption, high possibility in stripping, long phosphating time and the like are solved.

Owner:武汉金瑞欣精密工业设备有限公司

Stable and high-efficient room-temperature black phosphating presoak

InactiveCN107245712AAdapt to wideHigh blacknessMetallic material coating processesChromate conversion coatingNitrite

The invention discloses a stable and high-efficient room-temperature black phosphating presoak. Each liter of the presoak comprises the following raw materials by weight: 1-10 g of a blackening agent, 0.1-1 g of a blackening assistant, 0.5-5 g of a stabilizer, 1-5 g of an accelerant and the balance of water. The presoak can be applied on the surface of steel, so that blackness is high; a film layer binding force is firm; and the appearance is uniform. Besides, a conversion film is of a compact crystalline structure, so that the corrosion resistance of the phosphating conversion film can be greatly improved by the presoak; and besides, the presoak is extremely stable and high in treatment capacity, does not contain nickel, nitrites and other toxic or harmful substance and thus is low-pollution to the environment.

Owner:ANHUI JIANGNAN MACHINERY

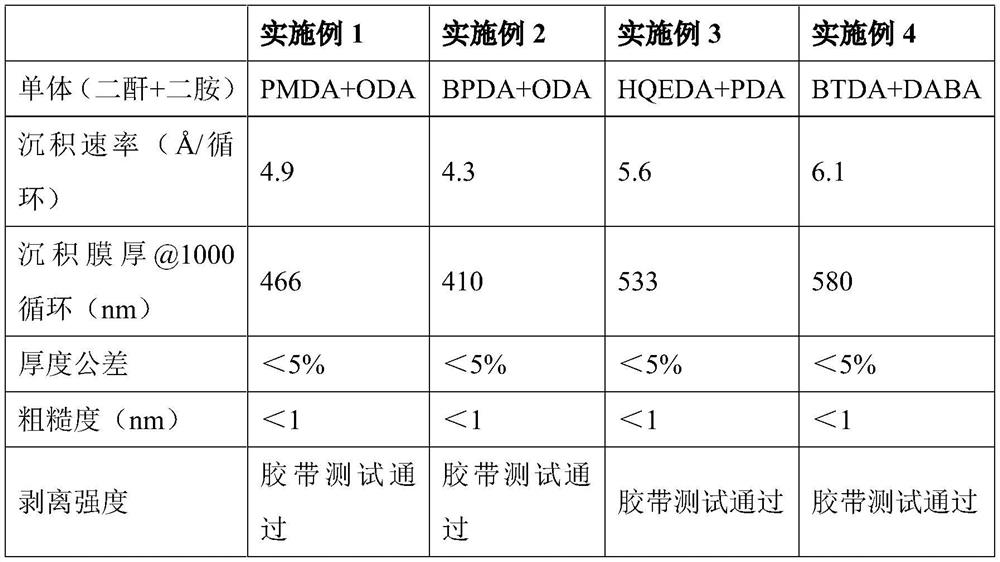

A kind of adhesive-free flexible copper clad laminate and preparation method thereof

ActiveCN108668450BUniform appearanceSmooth appearanceInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentAdhesive cementThin membrane

The invention provides an adhesive-free flexible copper-coated board and a fabrication method thereof. The fabrication method comprises the following steps of S1: performing aminopropyl alkoxy silaneand water modification processing on a surface of a copper foil by an atomic layer deposition method to obtain a surface-modified copper foil; S2, depositing a PI film on a surface of the surface-modified copper foil by the atomic layer deposition method; and S3, and performing rapid thermal processing on the PI film deposited in the step S2. The PI thin film prepared by the atomic layer deposition (ALD) method is uniform in film thickness, smooth in appearance and controllable in thickness, the bonding force between the PL thin film and the copper foil is favorable, 2L-FCCL of PI is obtained,and a novel environment-friendly process is provided for manufacturing the 2L-FCCL.

Owner:深圳市藤野电子科技有限公司

A kind of phosphating treatment solution for steel drawing at room temperature

Owner:武汉金瑞欣精密工业设备有限公司

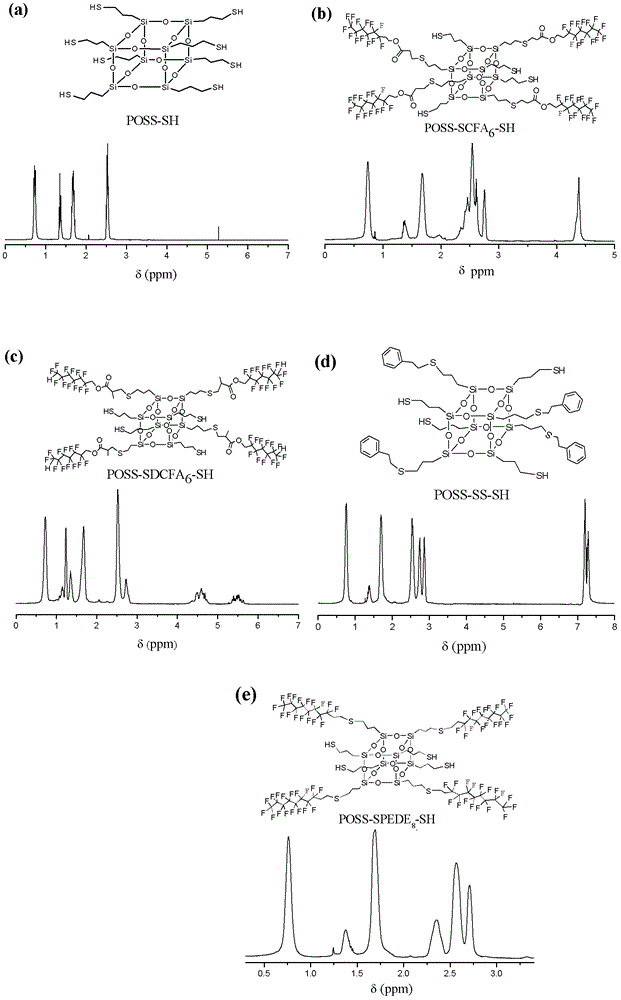

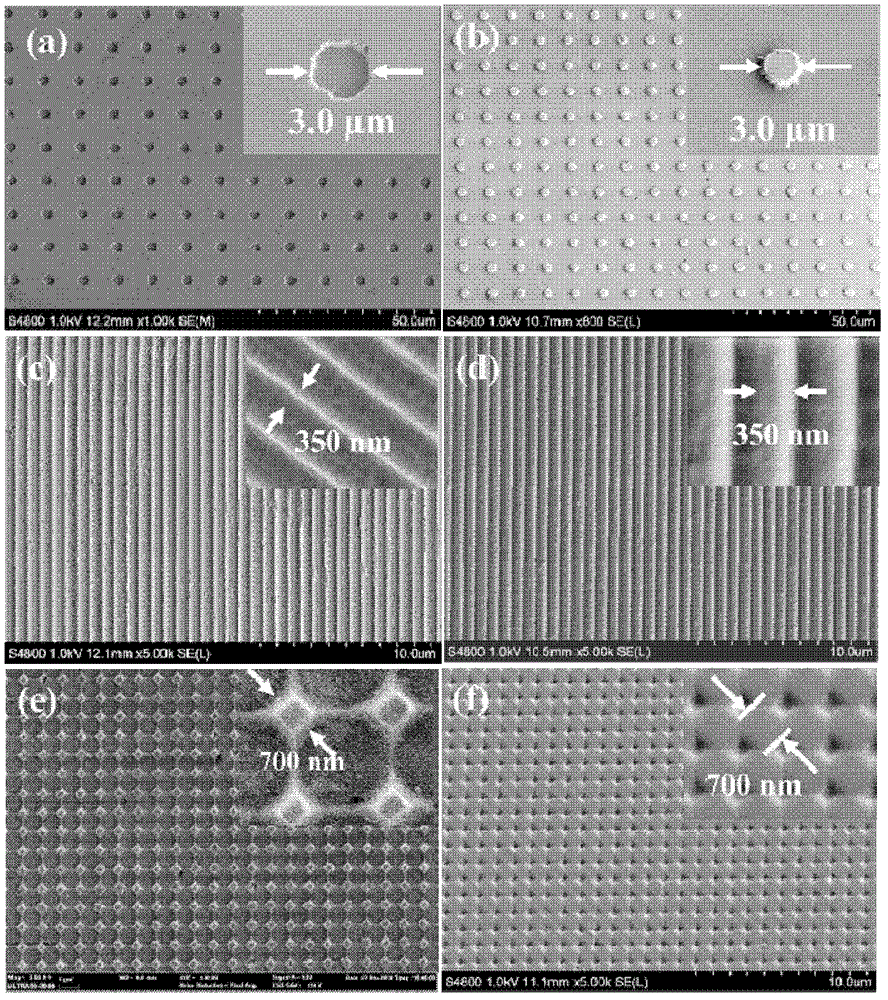

Low-magnification polysiloxane compound containing mercapto multifunctional group and its composition and imprinted soft template

InactiveCN103087087BImprove stabilityEasy to storeSilicon organic compoundsNanoinformaticsArylPolymer science

Provided are a polyhedral oligomeric silsesquioxane compound containing mercapto polyfunctional group shown as general formula (1), its composition used for preparing the soft template for imprinting and the imprinting process, wherein R1 is -CH2-CH2-CH2-SH, and m represents the integer of 3 to 12; R2 is unsubstituted or substituted alkyl group, unsubstituted or substituted alkoxy, unsubstituted or substituted ester group, and unsubstituted or substituted aryl group respectively, and the said substituent group is halogen; n represents the integer of 1 to 12. The composition is a high hydrophobic photoresist. When the composition is applied to prepare nanoimprinting template, a high precision structure can be achieved and the recycling rate of the template may be improved.

Owner:SHANGHAI JIAOTONG UNIV +1

Repairing method for unfilled corner and broken corner of shield segment

PendingCN111878114ANo sheddingNo strippingUnderground chambersTunnel liningWire brushStructural engineering

The invention discloses a repairing method for an unfilled corner and a broken corner of a shield segment. The repairing method comprises the following steps of S1, chiseling off uncompacted concreteand protruding aggregate particles at the broken corner; S2, thoroughly cleaning the broken corner on the shield segment, performing flushing with clear water, and waiting for dry state of the damagedsurface; S3, performing mortar mixing: preparing mortar, taking a proper quantity of materials according to the size of the broken corner, performing mixing according to general technical requirements, and uniformly stirring the mortar; S4, performing leveling and trimming after layer-by-layer filling is conducted, and after the mortar to be repaired is dried and hardened, grinding the surface tobe flat through a grinding machine; and S5, performing cleaning and wetting on the repaired part through a steel wire brush, and then performing plastering finishing on the repaired part through cement paste. The repairing method for an unfilled corner and a broken corner of a shield segment effectively overcomes the defects that through a conventional repairing method, repairing strength cannotmeet the requirement, the repaired part is easy to fall off, and chromatic aberration is serious, it is ensured that the overall performance of the repaired shield segment is more complete and attractive, the waterproof and anti-seepage performance of a tunnel is further enhanced, and the overall quality of the tunnel is ensured.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

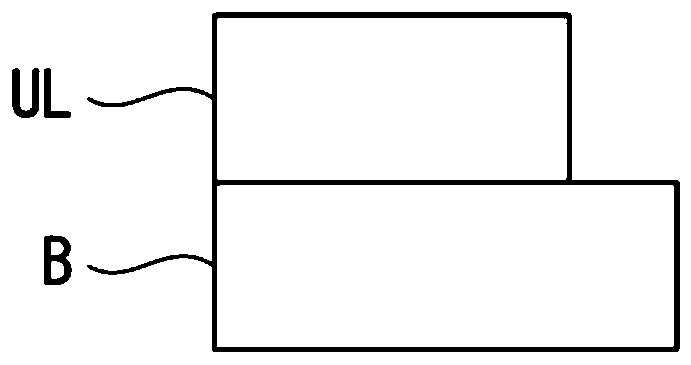

Steel belt surface colouring method

ActiveCN1304623CNo generationDense film structureSolid state diffusion coatingShielding gasHeating furnace

A process for coloring on the surface of steel band features that the steel band is treated in a heating furnace containing protecting gas at 280-560 deg.C for 2-10 min. Controlling the temp, the flow of protecting gas and time, the yellow, blue, or black color can be obtained.

Owner:ZHEJIANG BAINAI STEEL STRIP

Steel belt surface colouring method

ActiveCN1651595ANo generationDense film structureSolid state diffusion coatingShielding gasHeating furnace

A process for coloring on the surface of steel band features that the steel band is treated in a heating furnace containing protecting gas at 280-560 deg.C for 2-10 min. Controlling the temp, the flow of protecting gas and time, the yellow, blue, or black color can be obtained.

Owner:ZHEJIANG BAINAI STEEL STRIP

Capacitor coating with deep drawing resistant performance and high temperature yellowing resistance and preparation thereof

The invention discloses a non-yellowing capacitor coating at a high temperature having deep drawing resistance performance and a preparation method thereof. The capacitor coating in the invention is prepared from the materials according to the following parts by weight: 20 to 50 parts of hyperbranched polyester resin, 1 to 7 parts of saturated polyester resin, 3 to 12 parts of isocyanate, 0 to 0.5 parts of adhesion promoter, 0 to 0.15 parts of slipping wax, 0 to 0.3 parts of organic tin catalyst, 2.0 to 6.0 parts of resin modifier, 0.07 to 1.0 parts of defoamer, 0.15 to 0.20 parts of flattingagent, and 30 to 62 parts of solvents. The hyperbranched polyester resin, saturated polyester resin and isocyanate are put into a container so as to prepare a mixture after high-speed dispersing; therest of the materials are then put into the mixture so as to mix homogeneously by medium-speed dispersing, thereby obtaining the non-yellowing capacitor coating at a high temperature having deep drawing resistance performance. The capacitor in the invention has the characteristics of deep drawing resistance, good percentage elongation of coating film and no yellowing at a high temperature.

Owner:清远慧谷新材料技术有限公司

A kind of nickel-free one-component high corrosion resistance environmental protection black phosphating liquid

InactiveCN104032293BImprove corrosion resistanceHigh blacknessMetallic material coating processesNitriteHazardous substance

The invention discloses highly corrosion-resistant environment-friendly black phosphatizing liquid without nickel single component. Each liter of the treatment liquid consists of the following raw materials: 25-50g of main film forming agent, 5-25g of film forming aid, 0.1-3g of accelerant, 60-80g of grain refiner, 0.5-2g of stabilizer, 0.05-1g of blackening agent and 0.1-0.5g of blackening aid. The phosphatizing liquid disclosed by the invention can form a black phosphatized film on a steel surface by a one-step process. The phosphatized film has high blackness and high corrosion resistance, is uniform and avoids stripping; a copper sulfate spot test can reach 40min which is much longer than the national standard (2min); the phosphatizing liquid does not contain toxic and harmful substances such as nickel, nitrite and the like and causes little environmental pollution.

Owner:ANHUI JIANGNAN MACHINERY

A high-speed, low-shrinkage, low-smoke, halogen-free tight casing for 4g optical cable and its preparation method

ActiveCN103897256BHigh melting pointHigh softening temperatureFibre mechanical structuresLinear low-density polyethyleneFire retardant

Owner:JIANGSU LINRY NEW MSTAR TECH

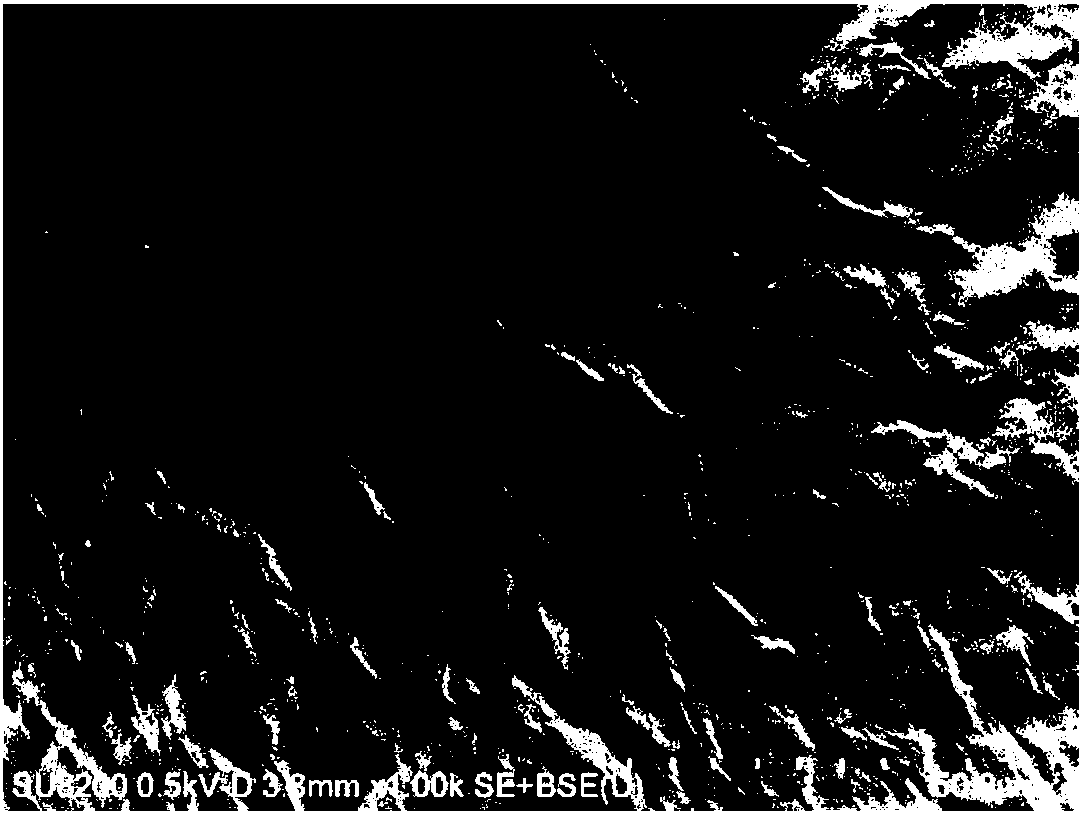

Coated cutting tool with excellent chipping resistance and wear resistance

ActiveCN108778585BImprove chip resistanceImprove wear resistanceTransportation and packagingMilling cuttersWear resistanceCoating

In the surface-coated cutting tool, the hard coating layer includes at least an (Al, Cr, Si, Cu)N layer, which is composed of a main phase, CrSi-rich particles and Al-rich particles dispersed in the main phase. By (Al 1‑α‑β‑γ Cr α Si β Cu γ ) 1‑x N x In the case of the composition of the main phase, CrSi-rich particles and Al-rich particles, the main phase satisfies 0.15≤α≤0.40, 0.05≤β≤0.20, 0.005≤γ≤0.05, 0.45≤x≤0.60, and the The CrSi-rich particles satisfy 0.20≤α≤0.55, 0.20≤β≤0.55, 0≤γ≤0.10, 0.02≤x≤0.35, and the Al-rich particles satisfy 0.10≤α≤0.25, 0.05≤β≤0.25, 0≤γ≤ 0.10, 0.02≤x≤0.35, where α, β, γ, and x are atomic ratios, and the area ratio of CrSi-rich particles in the upper layer cross section when observing particles with a long diameter of 100 nm or more in the upper layer cross section 0.20 area % to 2.0 area %, and the area ratio of the Al-rich particles in the cross section of the upper layer is 0.50 area % to 3.0 area %.

Owner:MITSUBISHI MATERIALS CORP

A kind of preparation method of skin-adhesive nano silver ion antibacterial dressing

ActiveCN107441545BDoes not affect sweatingSoft textureAbsorbent padsBandagesAdhesivePolyethylene glycol

The invention discloses a preparation method for skin adhering type nano-silver ion anti-microbial dressing. The method comprises the following steps: mixing the pure solvent chloroform and ethyl alcohol at volume ratio of (1-3):1, and by taking the mixture as a solvent, dissolving the polylactic acid and polyethylene glycol at volume ratio of (1-4):1 in the mass concentration of 8%-20%; adding the acquired mixed solution into an electrostatic spinning device for preparing the dressing; sterilizing the acquired dressing by utilizing a sterilizing method, taking out and airing; andsoaking the aired dressing into a silver nitrate solution, taking out and then airing, thereby acquiring the skin adhering type nano-silver ion anti-microbial dressing. The invention has the advantages that the use is comfortable, no pressure-sensitive adhesive is required for fixing, the problems of poor air permeability, poor adhesion, low fitting degree, adhesion to wound and incapability of isolating from and resisting against bacteria of the traditional medical dressing can be solved, the skin motion and sweat are not influenced in the use process and the dressing is thin and soft, reusable and free from residue on the skin.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com