Low-magnification polysiloxane compound containing mercapto multifunctional group and its composition and imprinted soft template

A technology of polysiloxane and compound, which is applied in the direction of photolithography of silicon organic compound, patterned surface, and nanotechnology for information processing, etc., which can solve the problem of limited use of soft templates and affect the precision of soft templates , Low moisture resistance of epoxy resin and other problems, to achieve the effect of easy repeated imprinting, high resistance to oxygen etching, and easy spin coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

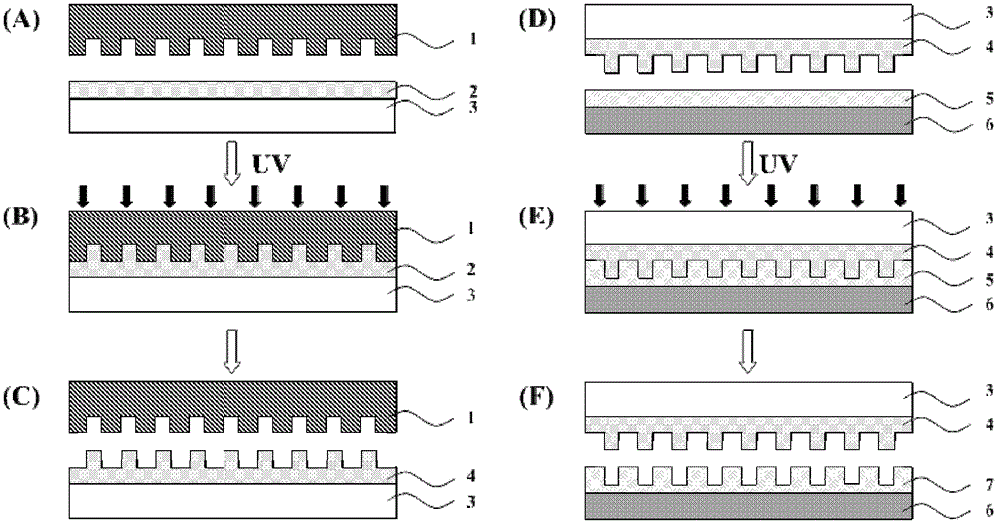

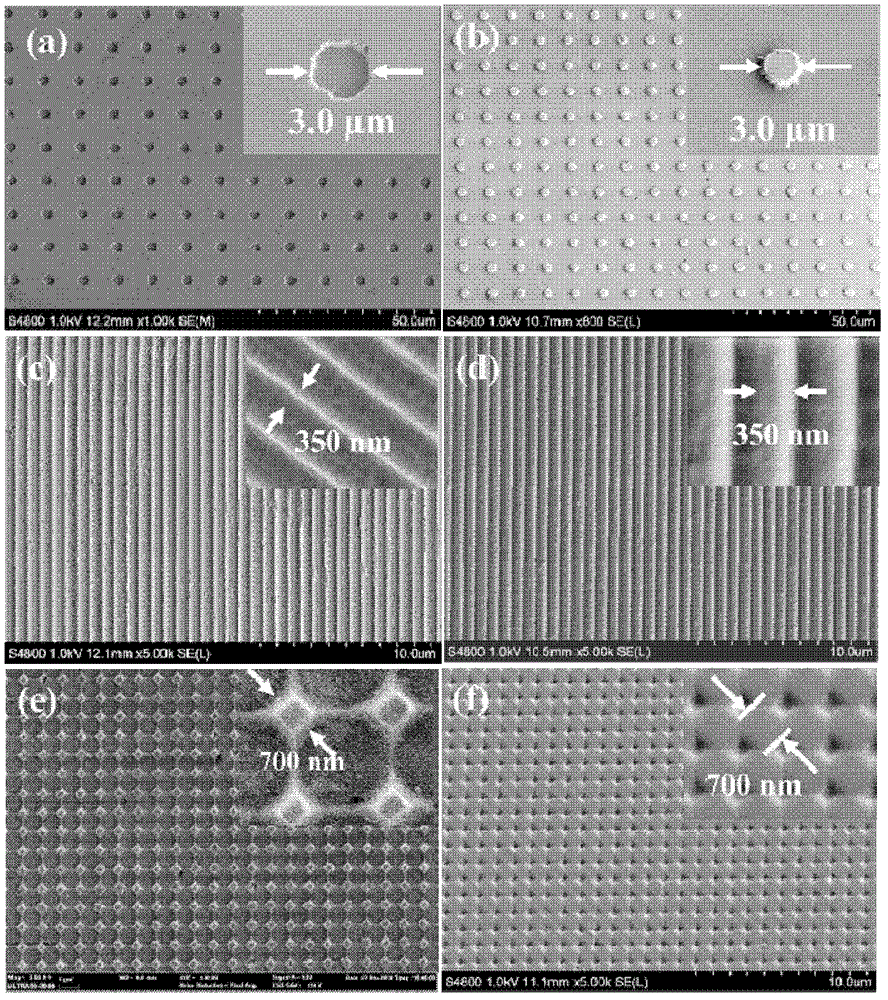

Method used

Image

Examples

preparation example Construction

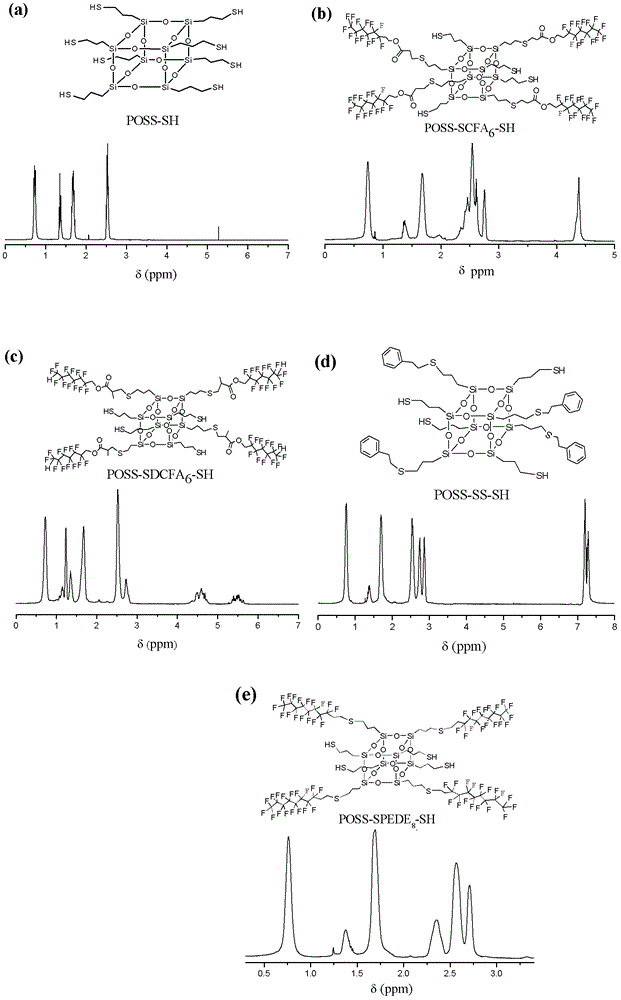

[0062] The present invention relates to the preparation method of the polysiloxane compound of the multifunctional group containing mercapto group shown in general formula (1), and this method comprises the following steps successively:

[0063] Step (1) can be according to the recognized technique as follows [1,2] To prepare:

[0064] That is, add silane monomer or its mixture and concentrated hydrochloric acid into a one-necked flask with a magnetic stirrer in sequence, then add a certain amount of methanol solvent to dissolve it, heat and reflux for a period of time, let it stand still, and filter off the upper layer clear liquid to obtain a milky white product, dissolve the milky white product with dichloromethane, then add excess methanol solvent to settle the product, repeat three times, use rotary evaporation, and evaporate the solvent to obtain a purified mercapto-containing low polysiloxane compound (referred to as POSS-SH).

[0065] The silane monomers used in the ...

Embodiment 1

[0121] Embodiment 1 The preparation of the low multiple polysiloxane compound (POSS-SH) containing mercapto group

[0122] Take 15.0ml of (3-mercaptopropyl)trimethoxysilane (TPS), 30ml of concentrated hydrochloric acid (37% mass concentration) in a single-necked flask with a magnetic stirrer, and measure 350ml of methanol solvent for dissolution. The mixture was stirred and refluxed at 90°C for 24 hours, left to stand, and the supernatant liquid was filtered off to obtain a milky white product. After dissolving the milky white product with dichloromethane, an excess of methanol was added to precipitate the product. After repeated three times, rotary steaming was performed. The dry solvent obtains the low polysiloxane compound (abbreviated as POSS-SH) containing mercapto group of purified product (see figure 1 (a)).

Embodiment 2

[0123] Example 2 Grafting 1H, 1H, 2H, the cage octapoly (γ-mercaptopropyl) silsesquioxane (referred to as POSS-SCFA) formed after 2H-perfluorooctyl acrylate 6 -SH) Preparation

[0124] With the POSS-SH that embodiment 1 makes and 1H, 1H, 2H, 2H-perfluorooctyl alcohol acrylate (being called for short CFA 6 ) in order to add in the dichloromethane of the airtight reagent bottle with magnetic stirrer, wherein POSS-SH and CFA 6 The molar ratio is 1:4, and the initiator I-907 accounts for 5‰ of the total mass of the entire reaction system. It is stirred and reacted under a 365nm ultraviolet lamp for 6 hours, and an excessive amount of n-hexane is added to allow it to settle. After standing still, filter out In the supernatant, the resulting transparent product was dissolved in dichloromethane, and then excessive n-hexane was added to precipitate out. After repeated three times, the solvent was evaporated to dryness by rotary evaporation to obtain the purified product cage octamer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com