Steel-backing non-electroplating iron alloy based friction material and preparation method and application for friction piece

A friction material, ferrous-based technology, applied in the field of powder metallurgy, can solve the problems of polluted water, energy consumption, air quality degradation, etc., and achieve the effects of wide source, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition and weight percentage of the iron-based friction material are as follows:

[0026] Iron powder 60%;

[0027] Metal binder 8%: selected from magnesium 2%, antimony 2%, molybdenum 2%, zinc 2%;

[0028] Friction modifier 25%: selected from copper 10%, lead 6%, feldspar 6%, wollastonite 3%;

[0029] Anti-wear agent 7%: selected from petroleum coke 5%, antimony sulfide 2%.

[0030] The specific preparation process of friction parts is as follows:

[0031] S1. Mixing: Weigh the above-mentioned metal bond, friction modifier and anti-wear agent in proportion, put them into the mixer and stir for 0.5 hours, then weigh the iron powder and put them into the mixer, and continue to stir for 2.5 hours to obtain Mixed powder;

[0032] S2. Blank making: According to the weight of different friction parts, put the uniformly mixed powder into the corresponding mold, and the 2 Pressed into a billet under the pressure;

[0033] S3. Making the steel back: According to ...

Embodiment 2

[0036] The friction part A2 was prepared according to the method of Example 1, the difference is that the composition and weight percentage of the iron-based friction material are as follows:

[0037] Iron powder 70%;

[0038] Metal binder 10%: selected from tin 5%, nickel 3%, antimony 2%;

[0039] Friction modifier 12%: selected from silicon dioxide 2%, magnesium oxide 10%;

[0040] 8% anti-wear agent: 8% selected from calcined graphite.

Embodiment 3

[0042] Friction part A3 was prepared according to the method of Example 1, with the difference that the composition and weight percentage of the iron-based friction material were as follows:

[0043] Iron powder 75%;

[0044] Metal binder 1%: selected from aluminum 1%;

[0045] Friction modifier 19%: selected from zinc oxide 8%, wollastonite 4%, vermiculite 4%, lead 3%;

[0046] 5% anti-wear agent: 5% selected from ferrous sulfate.

PUM

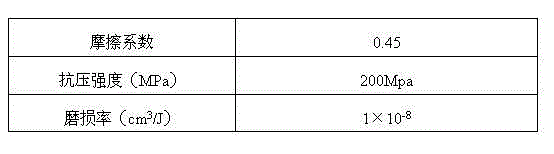

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com