Method for manufacturing silicon carbide semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of poor target use efficiency, poor film thickness uniformity, and short target life, so as to suppress excess Residue, improve the efficiency of use, the effect of uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] A method of manufacturing a silicon carbide Schottky barrier diode is illustrated as an example, and a method of manufacturing a silicon carbide semiconductor device according to an embodiment of the present invention will be described in detail below.

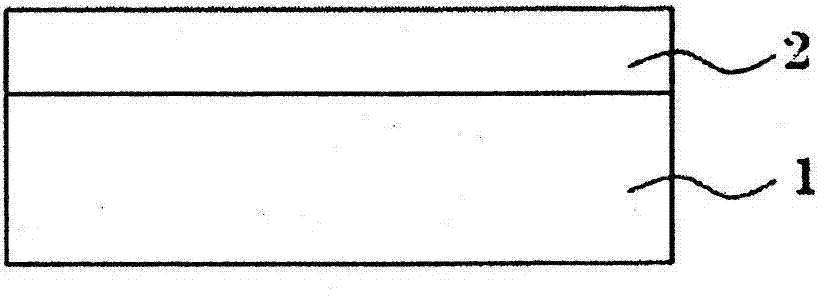

[0033] Figure 1~6 It is a cross-sectional schematic diagram for explaining the manufacturing process of the silicon carbide Schottky barrier diode concerning embodiment of this invention. First, if figure 1 As shown, the preparation is doped with e.g. 1 x 10 18 cm -3 A high-concentration n-type silicon carbide substrate 1 having a (0001) plane with a nitrogen thickness of 350 μm. Next, doped, for example, 1.8×10 16 cm -3 A low-concentration n-type silicon carbide drift layer 2 of nitrogen with a thickness of 6 μm.

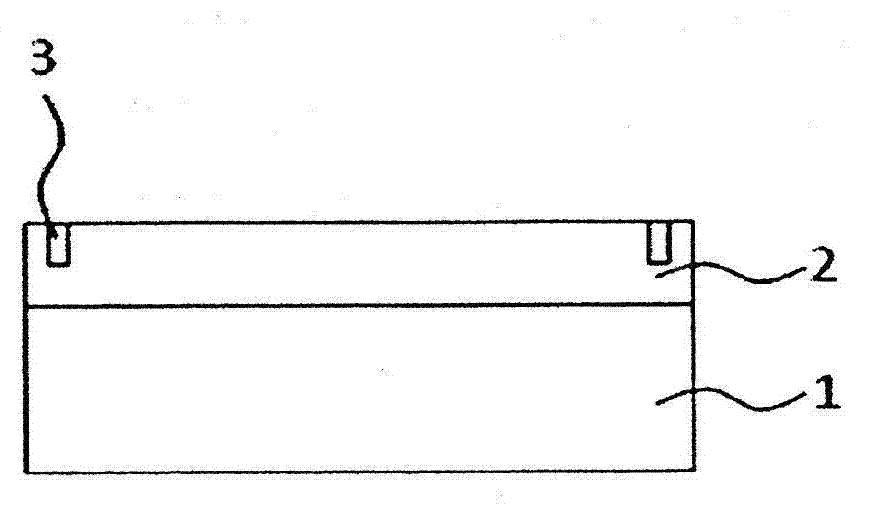

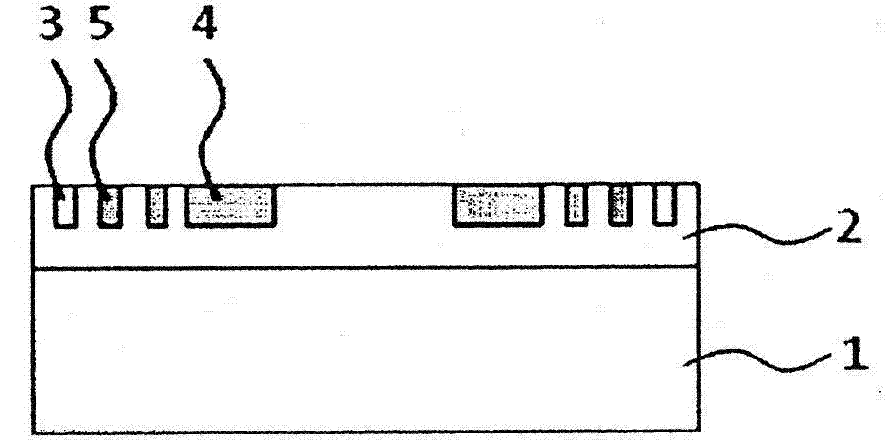

[0034] Next, if figure 2 As shown, in order to form an n-type region 3 for a channel stopper (channel stopper), for example, phosphorus (P) is implanted into the low-concentration n-type silicon car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com