Preparation apparatus and preparation method of polyimide thick membrane or polyimide ultrathick membrane

A polyimide thick film, polyimide technology, applied in the direction of coating, etc., can solve the problem that the polyamic acid solvent is difficult to volatilize, achieve the effect of improving volatilization, realizing recovery and recycling, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

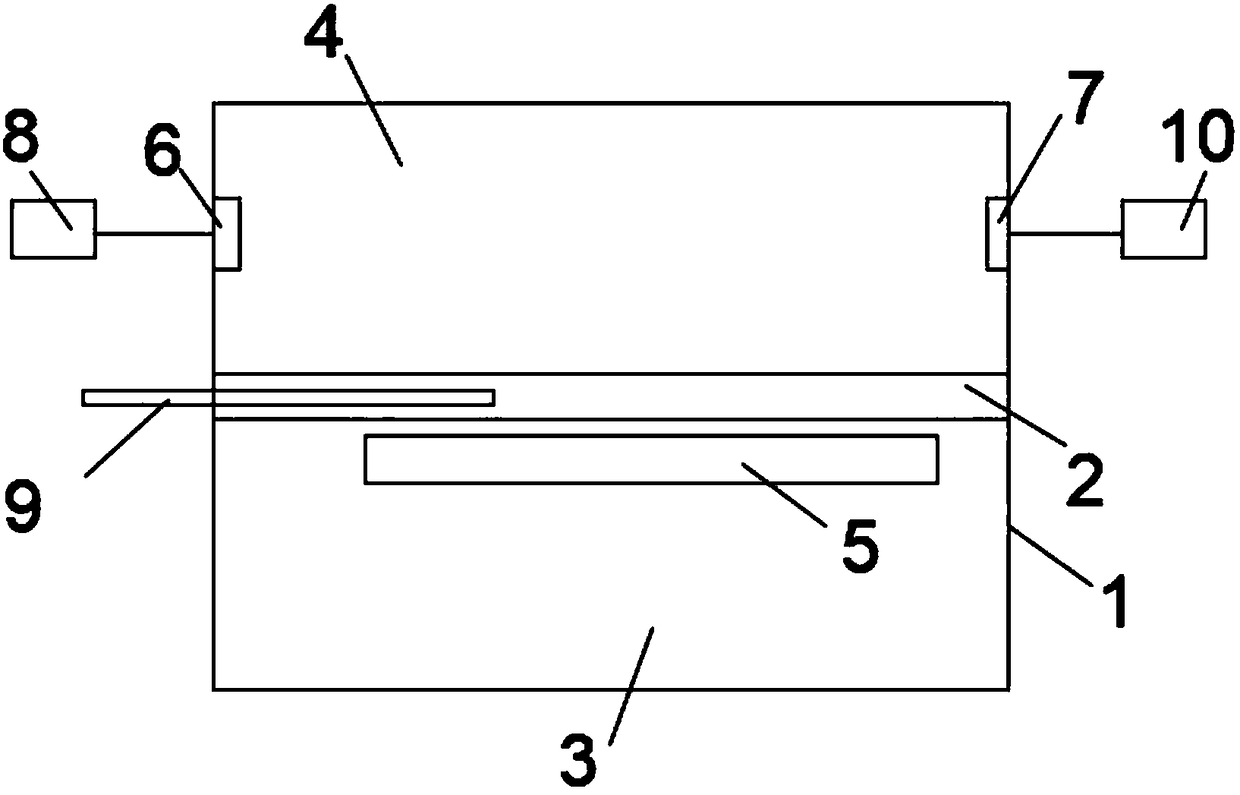

[0047] Such as figure 1 As shown, a preparation device for a polyimide thick film or a polyimide ultra-thick film of the present embodiment includes a housing 1, and the inside of the housing 1 is provided with a metal plate 2 parallel to the bottom surface of the housing 1. The metal plate 2 divides the interior of the housing 1 into two mutually independent heating chambers 3 and a cooling chamber 4 located on the upper part of the heating chamber 3, the top of the heating chamber 3 is provided with a heating pipe 5 parallel to the metal plate 2, The two sides of the cooling chamber 4 are respectively provided with an air inlet 6 and an air outlet 7, and the outer side of the housing 1 is provided with a blower 8, and the blower 8 communicates with the cooling chamber 4 through the air inlet 6. A thermocouple 9 is arranged in the middle of the metal plate 2 .

[0048] The preparation device of polyimide thick film or polyimide ultra-thick film of this embodiment, when polya...

Embodiment 2

[0060] The device for preparing a polyimide thick film or polyimide ultra-thick film in this embodiment is the same as that in Embodiment 1. Wherein, the material of the metal plate 2 is copper plate.

[0061] A condensation recovery device 10 is also provided outside the housing 1 , and the condensation recovery device 10 communicates with the cooling chamber 4 through the air outlet 7 .

[0062] The method for preparing a polyimide thick film or a polyimide ultra-thick film using the above-mentioned polyimide thick film or polyimide thick film preparation device of this embodiment includes the following steps:

[0063] Step 1: Under the protection of nitrogen atmosphere, add 20.00g of 3,4'-diaminodiphenyl ether into 330g of N,N-dimethylacetamide solution, stir at room temperature to dissolve, then slowly add 29.39g in several times

[0064] 3,3',4,4'-biphenyltetracarboxylic dianhydride was stirred for 6 hours after the addition to obtain a viscous polyamic acid solution (so...

Embodiment 3

[0071] The device for preparing a polyimide thick film or polyimide ultra-thick film in this embodiment is the same as that in Embodiment 1. Wherein, the material of the metal plate 2 is aluminum plate.

[0072] A condensation recovery device 10 is also provided outside the housing 1 , and the condensation recovery device 10 communicates with the cooling chamber 4 through the air outlet 7 .

[0073] The method for preparing a polyimide thick film or a polyimide ultra-thick film using the above-mentioned polyimide thick film or polyimide thick film preparation device of this embodiment includes the following steps:

[0074] Step 1: Under the protection of nitrogen atmosphere, add 13.00 g of p-phenylenediamine and 8.03 g of 4,4'-diaminodiphenyl ether into 390 g of N,N-dimethylformamide solution, stir at room temperature to dissolve, and slowly Add 47.60 g of 3,3',4,4'-biphenyltetracarboxylic dianhydride several times, and stir for 6 hours after the addition to obtain a viscous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com