Exposed polyurea waterproof repair coating, and preparation and construction method thereof

An exposed polyurea technology, applied in polyurea/polyurethane coatings, coatings, building maintenance, etc., can solve problems such as structural safety affected, poor adhesion of substrates, waste pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

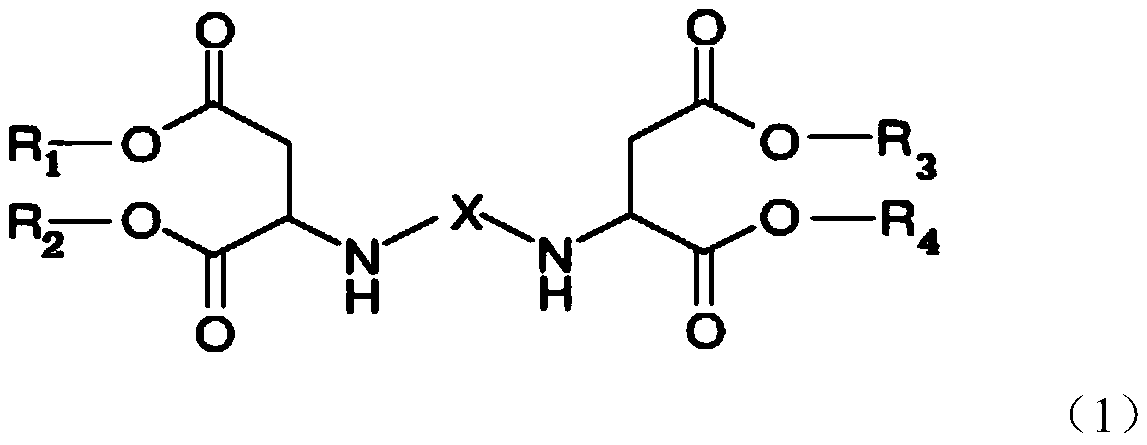

Method used

Image

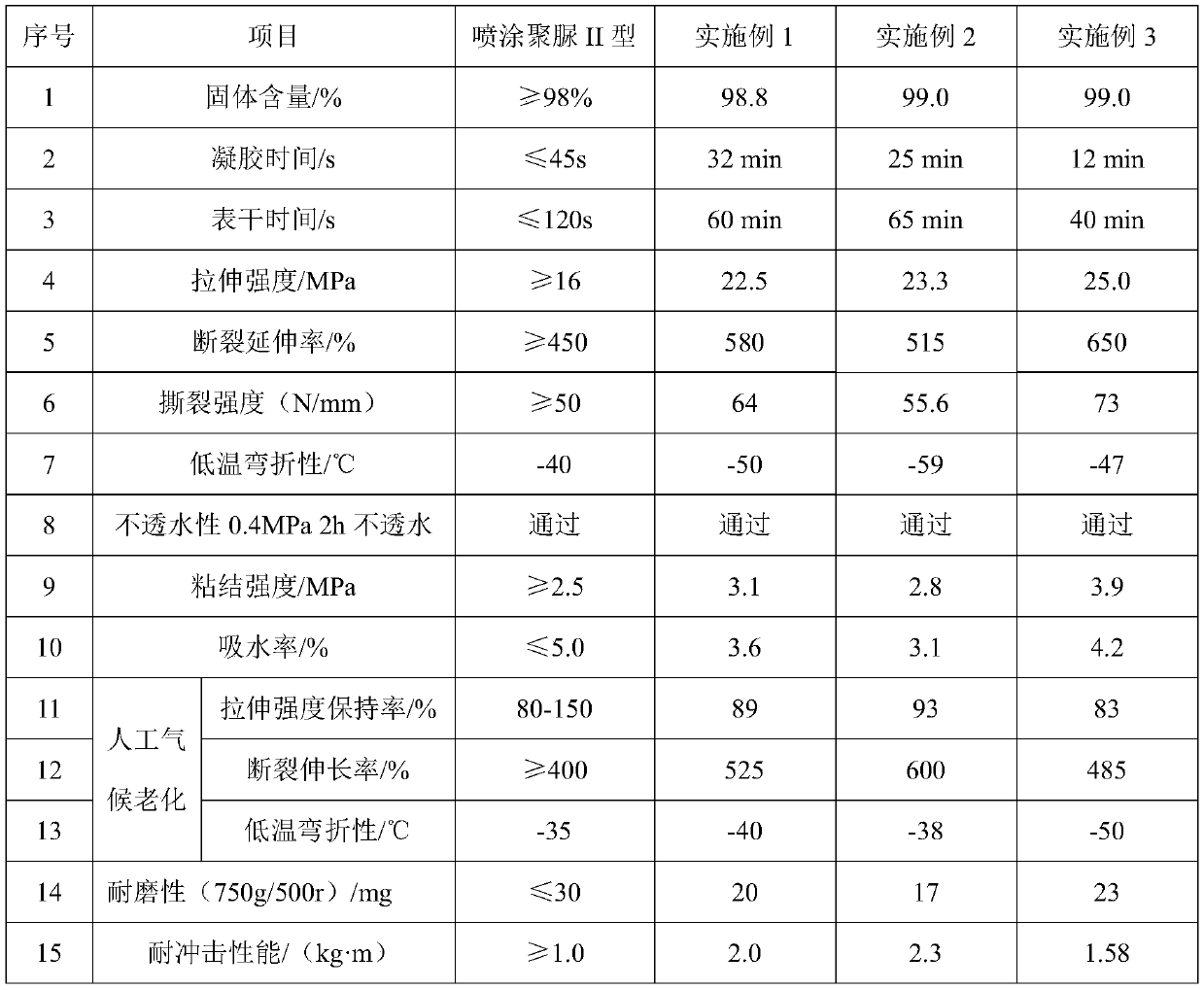

Examples

Embodiment 1

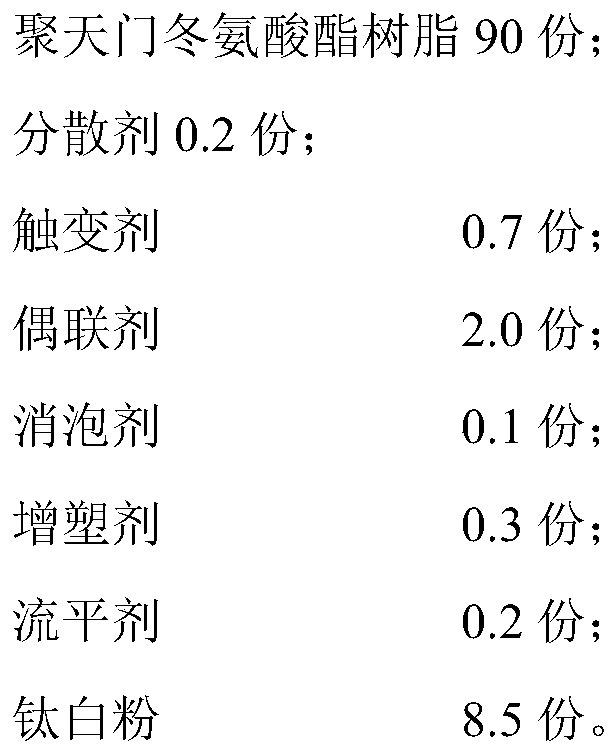

[0051] An exposed polyurea waterproof repair coating, which is used by mixing and deploying two components A and B. The compositions of A and B are as follows in parts by mass:

[0052] A component:

[0053] 80 parts of polyaspartic ester resins;

[0054] 10 parts of polyether polyamine;

[0055] Dispersant 0.2 part;

[0056] Thixotropic agent 0.7 part;

[0057] 2.0 parts of coupling agent;

[0058] 0.1 part of defoamer;

[0059] 0.3 parts of plasticizer;

[0060] Leveling agent 0.2 part;

[0061] 8.5 parts of titanium dioxide.

[0062] B component: polyether modified HDI trimer.

[0063] The polyether polyamine used is polyetheramine D230; the dispersant is dioctadecylmethyl tertiary amine; the thixotropic agent is fumed silica; the coupling agent is KH550; the defoamer is silicone defoamer; The plasticizer is dioctyl phthalate; the leveling agent is polyacrylate leveling agent.

[0064] Mix components A and B evenly in a mass ratio of 2:1 to obtain the exposed poly...

Embodiment 2

[0075] An exposed polyurea waterproof repair coating, which is used by mixing and deploying two components A and B. The compositions of A and B are as follows in parts by mass:

[0076] A component:

[0077]

[0078] B component: polyether modified HDI trimer.

[0079] The raw materials used in components A and B are the same as in Example 1, and components A and B are also mixed uniformly in a mass ratio of 2:1 to obtain the exposed polyurea waterproof repair coating of this example.

[0080] The preparation method of component A is: at room temperature, add polyaspartic acid ester resin, dispersant, thixotropic agent, coupling agent, defoamer, plasticizer, leveling agent, titanium dioxide in sequence to four In the flask, fully stir and disperse evenly, then grind to 100 mesh and discharge.

[0081] The preparation method of B component is the same as that of Example 1.

[0082] The difference between component A of this example and Example 1 is that Example 1 contains...

Embodiment 3

[0084] An exposed polyurea waterproof repair coating, which is used by mixing and deploying two components A and B. The compositions of A and B are as follows in parts by mass:

[0085] A component:

[0086] 80 parts of polyaspartic acid ester resin A;

[0087] 15 parts of polyaspartic acid ester resin B;

[0088] 0.5 parts of dispersant;

[0089] Thixotropic agent 0.5 part;

[0090] 1.5 parts of coupling agent;

[0091] 0.3 part of defoamer;

[0092] 0.1 parts of plasticizer;

[0093] Leveling agent 0.5 part;

[0094] Titanium dioxide 8.0 parts.

[0095] B component: polyether modified IPDI trimer.

[0096] The polyether polyamine used is polyetheramine D230; the dispersant is cetyl dimethyl tertiary amine; the thixotropic agent is bentonite; the coupling agent is KH570; the defoamer is silicone defoamer; plasticizer It is dibutyl phthalate; the leveling agent is polyacrylate leveling agent.

[0097] Mix components A and B evenly in a mass ratio of 2:1 to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com