Coated cutting tool with excellent chipping resistance and wear resistance

A cutting tool and surface coating technology, which is applied in the field of surface coating cutting tools, can solve the problems of reduced wear resistance, high impact and intermittent properties, and reduced toughness, and achieve excellent chipping resistance and wear resistance , Excellent cutting performance, excellent chipping resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] As raw material powders, medium-coarse WC powder with an average particle size of 5.5 μm, fine-grained WC powder with an average particle size of 0.8 μm, TaC powder with an average particle size of 1.3 μm, NbC powder with an average particle size of 1.2 μm, and an average ZrC powder with a particle size of 1.2 μm, Cr with an average particle size of 2.3 μm 3 C 2 Powder, VC powder with an average particle size of 1.5 μm, (Ti, W)C [in mass ratio, TiC / WC=50 / 50] powder with an average particle size of 1.0 μm, and Co powder with an average particle size of 1.8 μm , and these raw material powders were mixed into the compounding composition shown in Table 1, and paraffin wax was further added and ball milled in acetone for 24 hours. After drying under reduced pressure, it was extruded with a pressure of 100Mpa and stamped into a prescribed shape. Various compacts, these compacts are heated to a specified temperature in the range of 1370-1470 °C at a heating rate of 7 °C / min i...

Embodiment 2

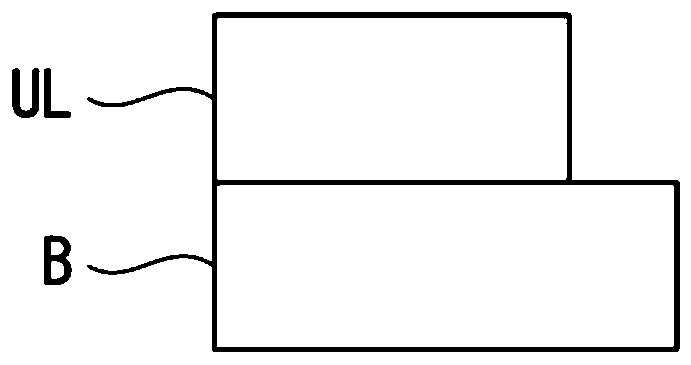

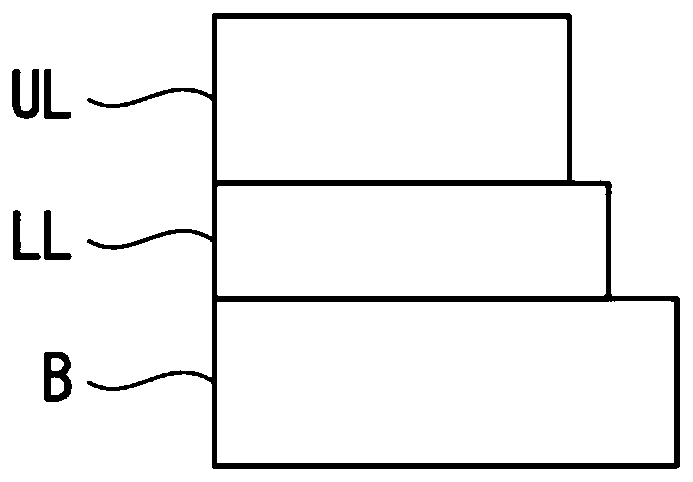

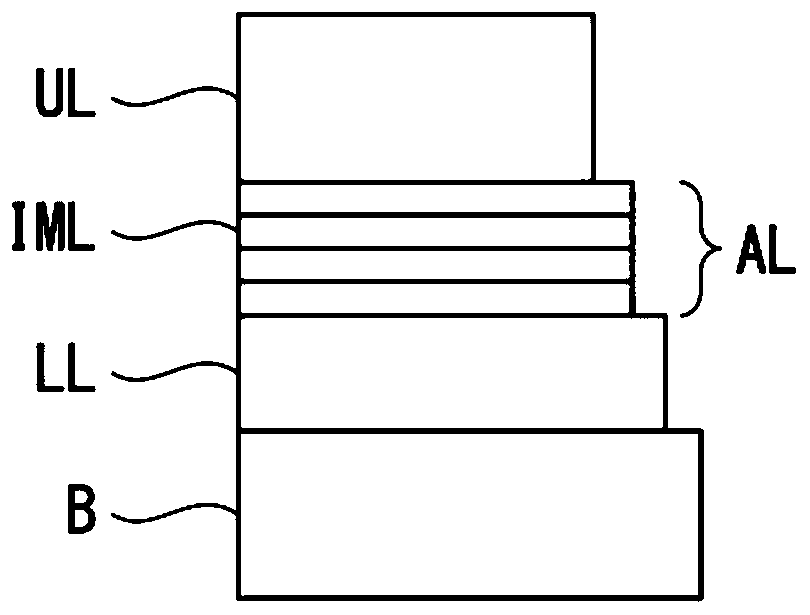

[0173] With respect to the tool substrates 1 to 3 used in Example 1, coated tools 11 to 15 of the present invention having a hard coating layer composed of a lower layer and an upper layer, and coated tools of the present invention having a hard coating layer composed of a lower layer were produced by the following method. 1. The coated tools 16 to 20 of the present invention having a hard coating layer composed of an intermediate layer and an upper layer, wherein the intermediate layer is composed of an alternate lamination structure of thin layers A and thin layers B.

[0174] (a) Tool bases 1 to 3 are installed along the outer periphery at a position spaced apart from the central axis on the turntable of the AIP device shown in FIG. A target (cathode electrode) composed of an Al-Ti-Si alloy of a given composition, and a target (cathode electrode) composed of an Al-Cr-Si-Cu alloy of a predetermined composition is arranged on the other side, in the same manner as in Example 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com