Steel belt surface colouring method

A surface coloring and steel strip technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of low environmental cost and extremely difficult control of quality and color uniformity. The layer structure is dense, no peeling, and the effect is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

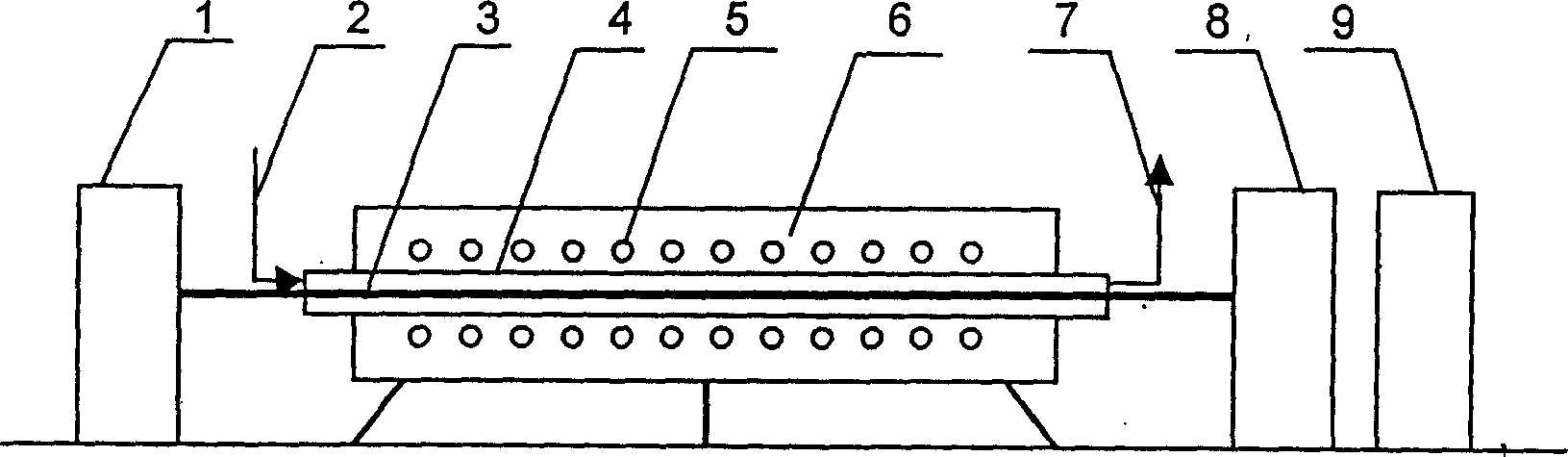

Image

Examples

Embodiment 1

[0012] The 0.5mm thick steel strip passes through the 10m long coloring treatment furnace at a speed of 5m / min. The actual residence time of the steel strip in the furnace is 2min, the furnace temperature is 280°C, and the ammonia decomposition gas flow rate is 2m 3 / h, to obtain a uniform color, yellow steel strip.

Embodiment 2

[0014] The 0.5mm thick steel strip passes through a 10m long coloring treatment furnace at a speed of 2m / min. The actual residence time of the steel strip in the furnace is 5min, the furnace temperature is 350°C, and the ammonia decomposition gas flow rate is 1m 3 / h, to obtain a uniform color, blue steel strip.

Embodiment 3

[0016] A 2mm thick steel strip passes through a 10m-long coloring treatment furnace at a speed of 1m / min. The actual residence time of the steel strip in the furnace is 10min, the furnace temperature is 560°C, and the flow rate of methanol cracking gas is 0.2m 3 / h to obtain a uniform and black steel strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com