A kind of adhesive-free flexible copper clad laminate and preparation method thereof

An adhesive and flexible technology, used in the manufacture of printed circuits, the manufacture of printed circuit precursors, and the improvement of metal adhesion to insulating substrates. , The effect of uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present application provides a method for preparing an adhesive-free flexible copper-clad laminate. In a specific embodiment, it includes the following steps:

[0038] S1: Aminopropylalkoxysilane and water were used to modify the surface of the copper foil by atomic layer deposition to obtain a surface-modified copper foil;

[0039] S2: Depositing a PI film on the surface of the surface-modified copper foil by atomic layer deposition;

[0040] S3: performing rapid heat treatment on the PI film deposited in step S2.

[0041] In some preferred embodiments, at least one of the following conditions may also be preferred:

[0042] Step S1 comprises the following steps:

[0043] S1.1: Place the copper foil in an atomic layer deposition reactor at 120-150°C for pretreatment to remove physically adsorbed water molecules on the surface of the copper foil; the pretreatment time is preferably about 30 minutes;

[0044] S1.2: Deposit aminopropylalkoxysilane on the surface of...

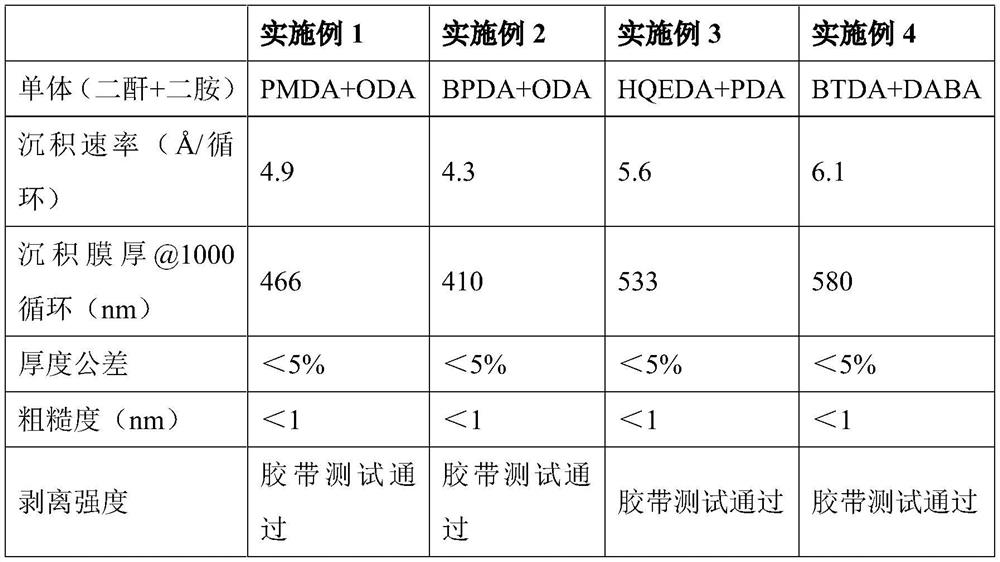

Embodiment 1

[0065] Raw materials:

[0066] Pyromellitic dianhydride (PMDA)

[0067] Diaminodiphenyl ether (ODA)

[0068] Nitrogen (carrier / cleaning gas)

[0069] RA copper foil (thickness: 1 / 2OZ)

[0070] γ-Aminopropyltrimethoxysilane (APTMS)

[0071] steam

[0072] instrument:

[0073] F-120 type ALD reactor (Finland)

[0074] PEO601 RTA rapid thermal annealing furnace (Germany)

[0075] Experimental steps:

[0076] S1: Using the atomic layer deposition method, the surface of the copper foil is subjected to APTMS-H 2 O modification treatment, obtain surface modified copper foil, wherein, copper foil adopts rolling copper foil (RA copper foil), concrete steps are as follows:

[0077] S1.1 Place the copper foil in an ALD reactor at 120-150°C for pretreatment for 30 minutes to remove water molecules physically adsorbed on the surface of the copper foil;

[0078] S1.2 Deposit APTMS by ALD on the surface of copper foil (reaction pressure: 20-50mbar; deposition temperature: 90-130°C;...

Embodiment 2

[0093] The difference from Example 1 is that this example is the ALD deposition of BPDA-ODA type PI on the copper foil surface, and the specific deposition cycle and reaction conditions in step S2 are: BPDA gas pulse (deposition temperature: 170 ° C, pulse Time: 3.0s)-N 2 (Purge time: 1.5-3.0s)-ODA gas pulse (deposition temperature: 150°C, pulse time: 2.0s)-N 2 (Purge time: 1.5-3.0s). All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com