Transmission coil for magnetically-coupled resonant wireless power transmission system

A resonant radio and transmission coil technology, applied in electromagnetic wave systems, transformers/inductor coils/windings/connections, circuits, etc., can solve problems such as low transmission efficiency, low coil quality factor, and large parasitic capacitance, and achieve unity Good, the quality factor is improved, and the effect of large self-inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

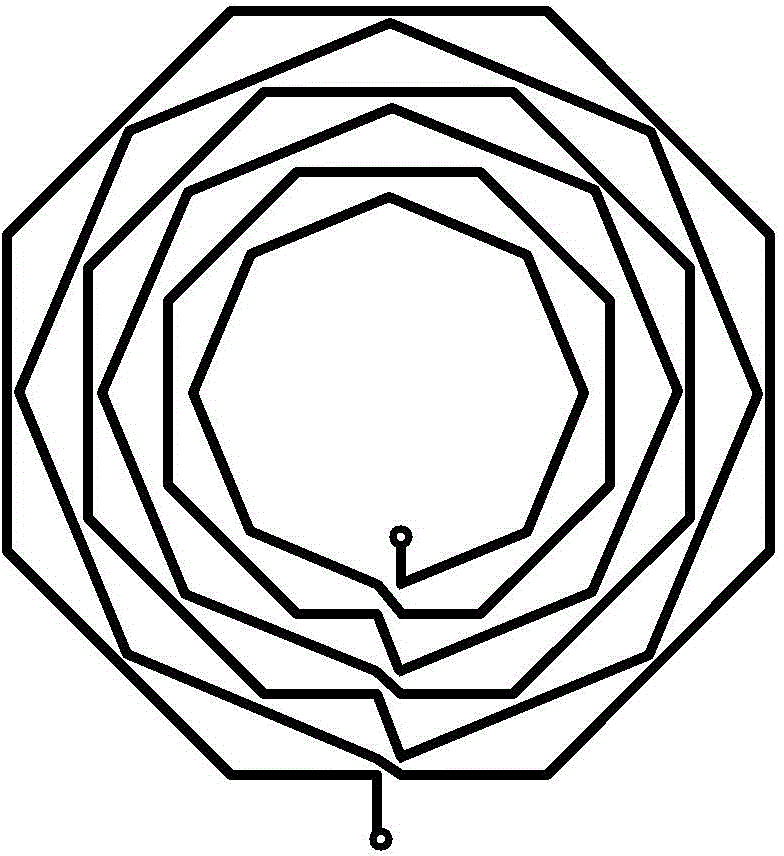

[0010] Specific embodiment one: reference figure 1 To describe this embodiment in detail, a transmission coil for a magnetic coupling resonance wireless power transmission system described in this embodiment includes a multi-turn coil, each turn of the coil is a regular polygon, and the geometry of each turn of the coil The centers are all located at the same point, all the turns of the coils are located on the same plane, and the vertex of any one turn of the polygonal coil is directly opposite to the midpoint of the corresponding side of the adjacent turn.

[0011] The transmission coil used in the magnetic coupling resonance wireless power transmission system described in this embodiment adopts a planar structure, that is, all turns of the coil are located on the same plane, which is convenient for processing in a printed circuit board; It is a polygonal structure, and the adjacent two-turn polygons are angularly misaligned, that is, the vertex of any one-turn polygon is direc...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment is a further description of a transmission coil used in a magnetic coupling resonance wireless power transmission system described in Embodiment 1. In this embodiment, all turns of the coil have the same winding direction.

specific Embodiment approach 3

[0013] Specific embodiment three: This embodiment is a further description of a transmission coil used in a magnetic coupling resonance wireless power transmission system described in specific embodiments 1 or 2. In this embodiment, any one-turn polygonal coil and phase The coils of adjacent turns are connected end to end.

[0014] The adjacent coils are connected end-to-end, that is, the head end of one turn of the coil is connected to the tail end of the adjacent previous turn, and the tail end is connected to the head end of the next adjacent turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com