CCD imaging system calibration and adjustment device

An imaging system and calibration technology, used in image analysis, image communication, image data processing, etc., can solve the problems of low measurement accuracy and poor measurement reproducibility, and achieve the goal of avoiding manual operation, easy operation, and measurement accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

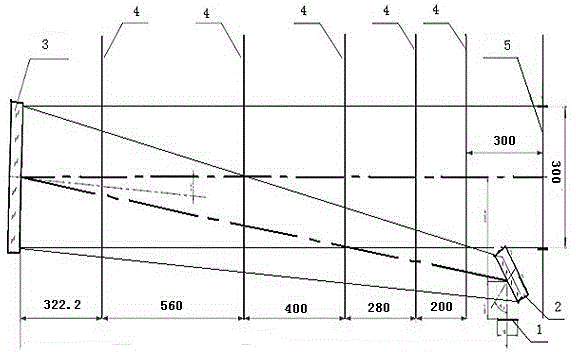

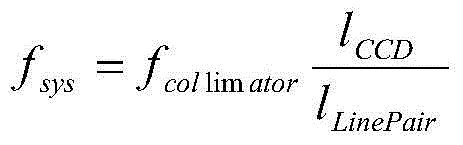

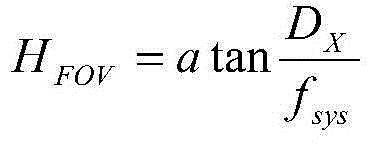

[0015] Embodiment 1: as figure 1 As shown, this embodiment provides a CCD imaging system calibration adjustment device that is less affected by human factors, has high measurement accuracy, and has a high degree of automation, including a collimator (not shown in the figure), and a front end of the collimator An exit aperture 5 is provided, and the rear end of the collimator is provided with a parabolic primary mirror 3; one side of the collimator is provided with a target 1 (the target 1 can be arbitrarily replaced according to the required test parameters), so The position of the target 1 is close to the exit diaphragm 5 and is set at 90 degrees with the exit diaphragm, and the collimator is provided with a plane secondary mirror 2, a parabolic primary mirror 3 and more than one barrier screen 4; the barrier The screen 4 is provided with a light hole. The plane secondary mirror 2 is located at the front end of the collimator and behind the exit diaphragm 5, the parabolic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com