Casting process of excavator bucket teeth

A technology of excavator bucket teeth and casting process, which is applied to the casting process of excavator bucket teeth and the processing field of excavator accessories, can solve problems such as short service life, and achieve the advantages of improving service life, improving service life and increasing density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

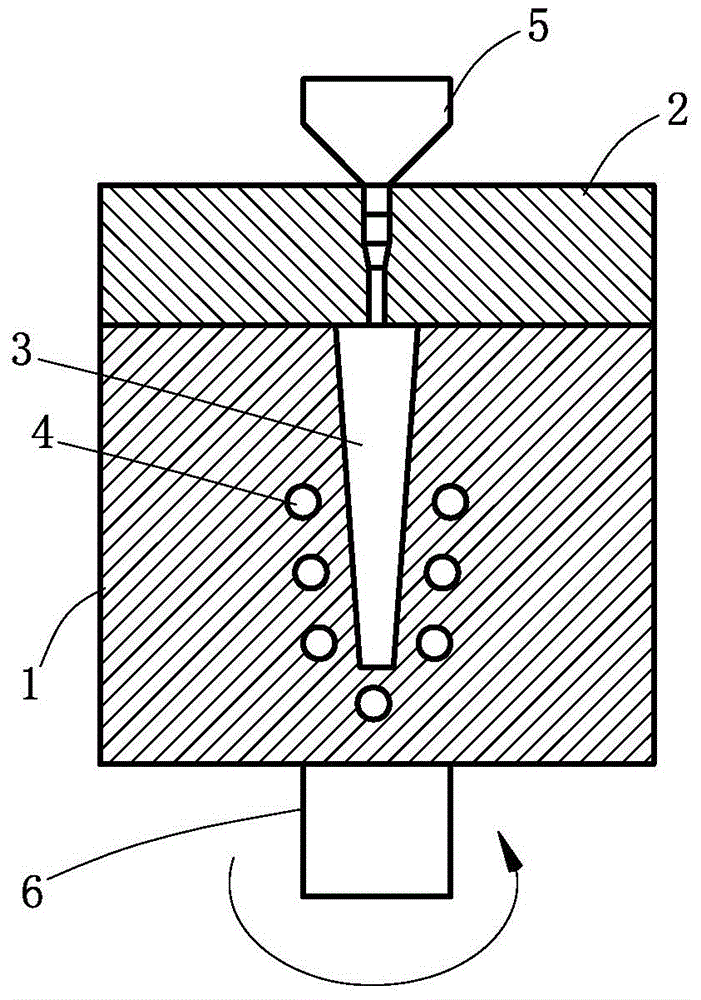

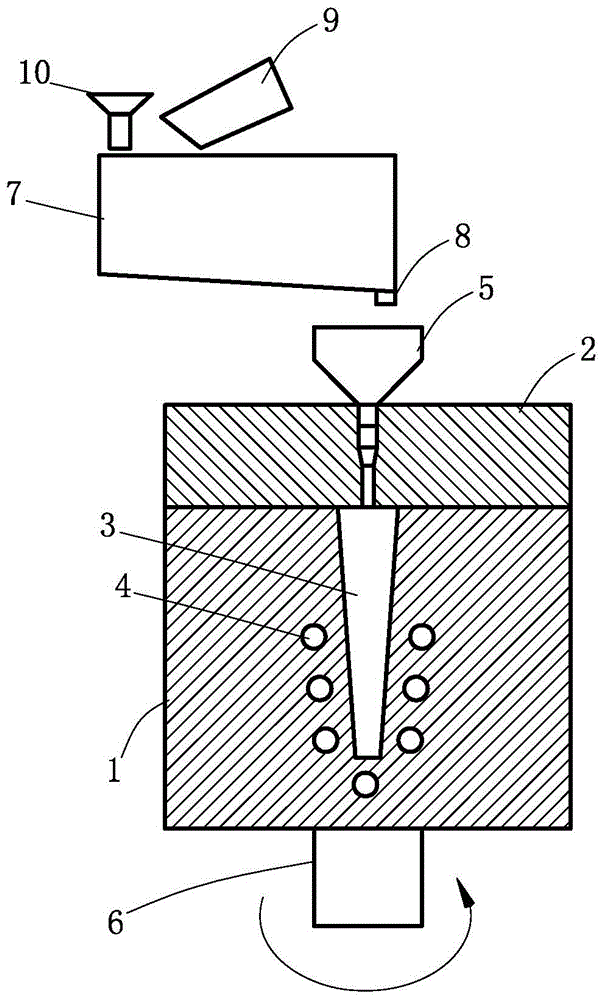

[0033] like figure 1 and figure 2 Commonly shown, the present invention provides a casting process for bucket teeth of an excavator, comprising the following steps: (1) making a sand box, the sand box includes an upper sand box 2 and a lower sand box 1, and the upper sand box 2 is provided with Sprue cup 5 and sprue, bucket tooth cavity 3 is provided on the lower sand box 1, the bucket tooth cavity 3 is frustum-shaped, electric heating tube 4 is arranged around the bucket tooth cavity 3, the upper sand box 2 and the lower sand box The box 1 is fixedly installed on a turntable 6 driven by a power unit after mold closing. The center of rotation of the bucket tooth cavity 3 is consistent with that of the turntable 6. The sprue adopts a straight sprue to ensure the smooth flow of molten steel. Casting; (2) smelting, when the temperature reaches 1560°C, feed silicon-calcium-barium core wire for immersion deoxidation treatment, control the calcium weight percentage to 0.0015-0.002...

Embodiment 2

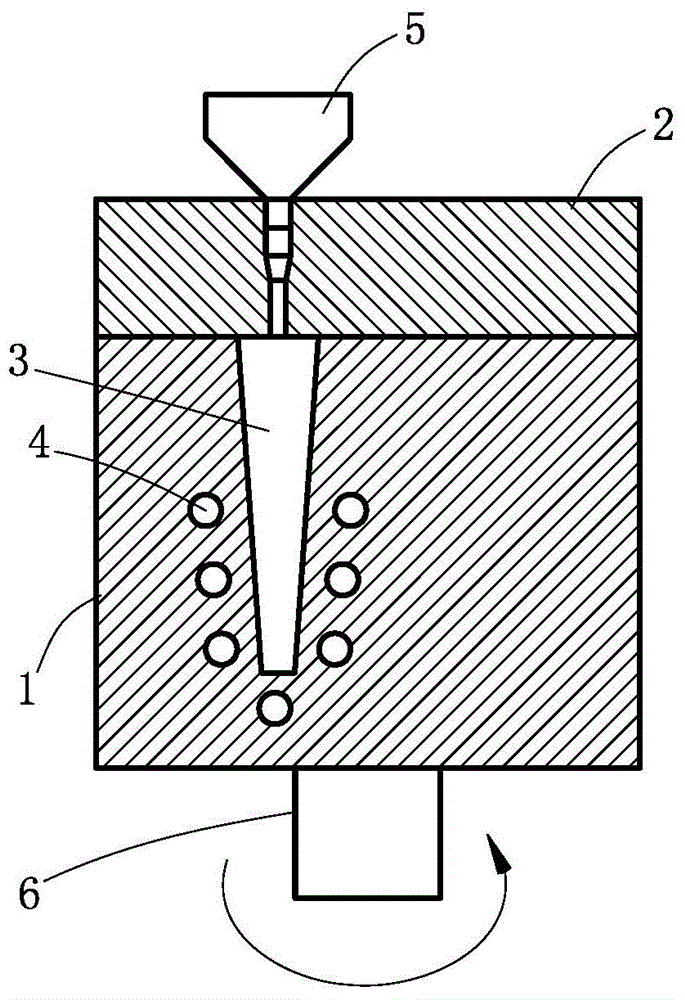

[0036] like image 3 As shown, the present invention provides a casting process for excavator bucket teeth, the process is basically the same as that of Embodiment 1, the difference is that the bucket tooth cavity 3 is flat, and the bucket tooth cavity 3 and the rotating table 6 The center of rotation is set eccentrically, so that the wear-resistant and hardened alloy materials are piled up on one side during casting, which is especially suitable for the bucket teeth of the ground-breaking type and the bucket tooth of the shovel type, which greatly improves the hardness and wear resistance of the lower surface of the bucket teeth , prolong the service life of this type of bucket teeth.

Embodiment 3

[0038] like Figure 4 As shown, the present invention provides a casting process for excavator bucket teeth, the process is basically the same as that of Embodiment 2, the difference is that several flat bucket tooth cavities 3 are eccentrically arranged around the center of rotation, and the cast The radially arranged flat sprue and the vertically arranged straight sprue are used to cast several bucket teeth at the same time, which greatly improves the forming efficiency of the bucket teeth, realizes mass production, and further reduces production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com