Inner-cooling type hobbing cutter

A hob, cold type technology, applied in the direction of milling cutter, gear tooth manufacturing device, gear teeth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

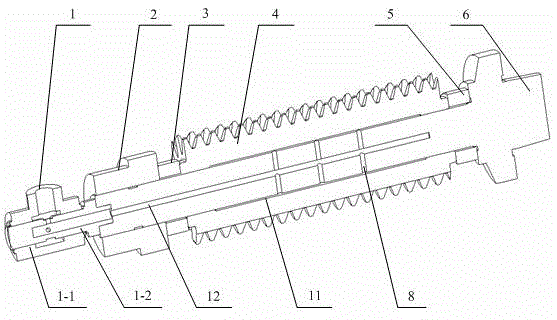

[0023] As shown in Figure 1, an internally cooled hob includes a cutter bar 6 and a hob 4, and the hob 4 is sleeved on the cutter bar 6; the hob 4 is connected by a key 13 to fix its axial rotation degree of freedom. The washers 3 and 5 fix the degree of freedom of axial movement, and the other four degrees of freedom are restricted by the cutter rod 6, so as to be fixed on the cutter rod 6; the hob head seat 2 plays the role of supporting the cutter rod 6, and also through the thread Connect with rotary joint 1.

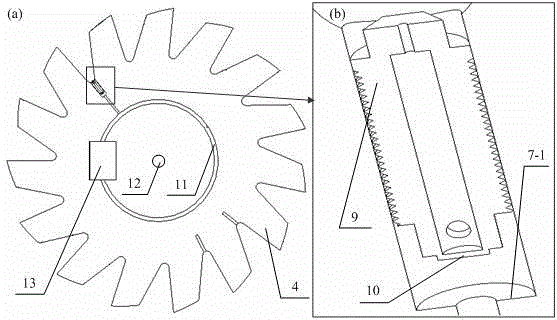

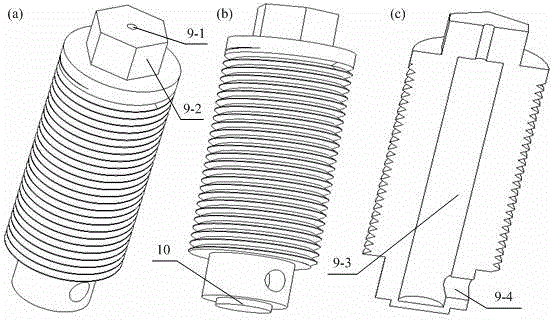

[0024] See Figure 1 and figure 2 , the present invention is based on the existing hob structure, the hob 4 is located in the chip pocket corresponding to the rake face of the cutter tooth and is provided with an oil hole 7; the upper part of the oil hole 7 is correspondingly provided with a hole plug 9, and the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com